Engine/valvetrain with shaft-mounted cam followers having dual independent lash adjusters

一种气门机构、发动机的技术,应用在发动机元件、机器/发动机、阀装置等方向,能够解决气门操作不能精确地同步、磨损、气门构件磨损等问题,达到减少机械加工复杂性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

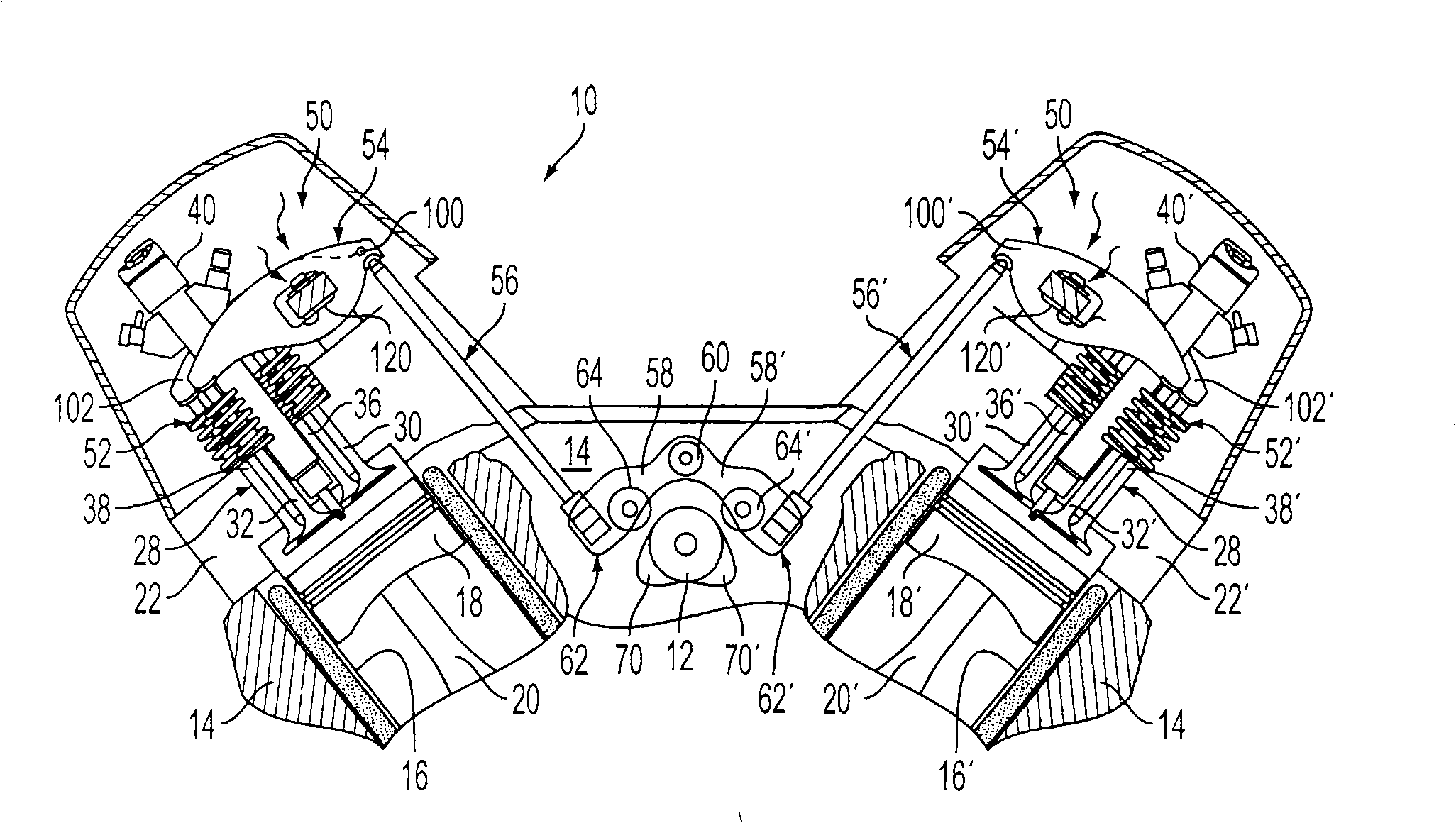

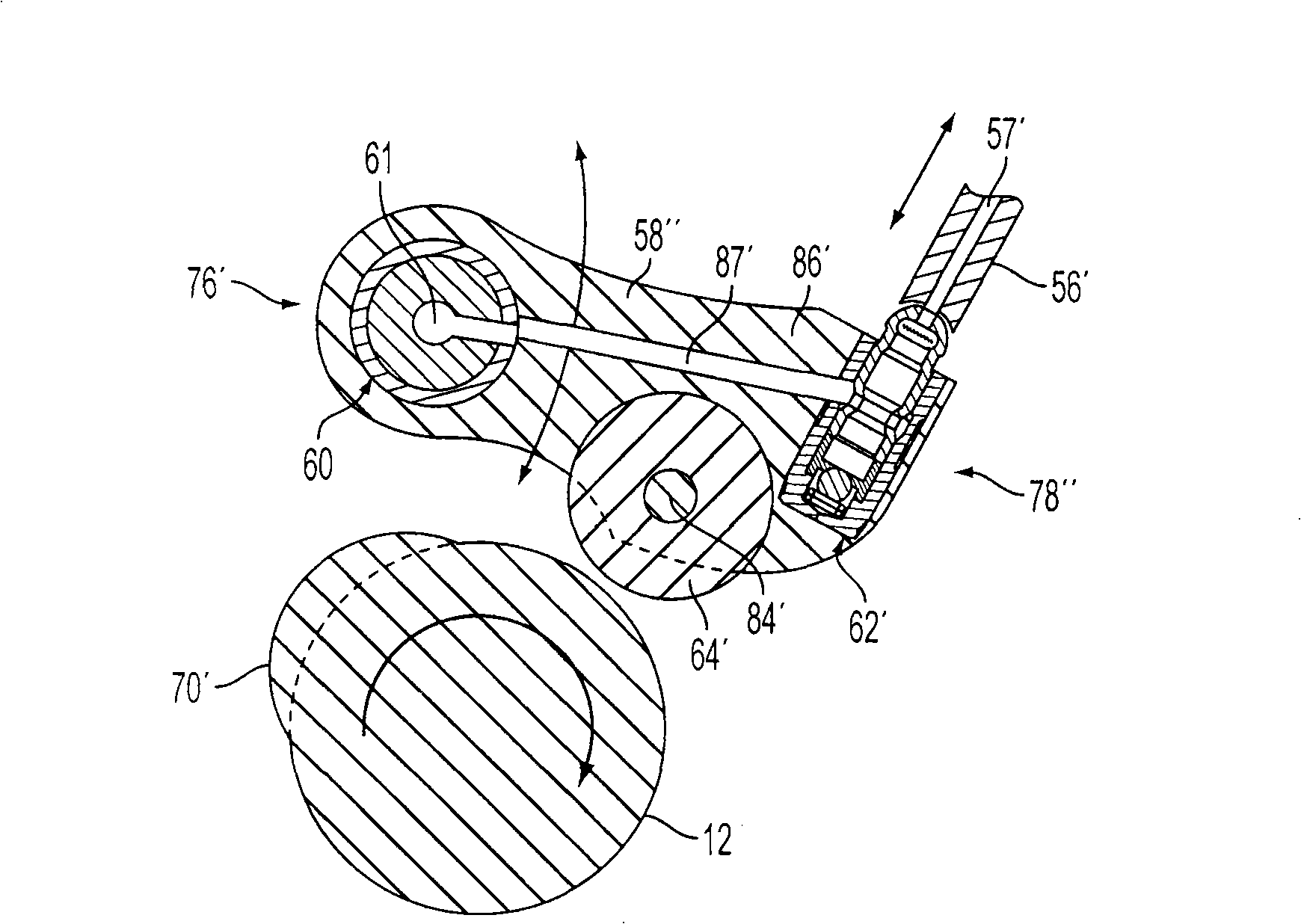

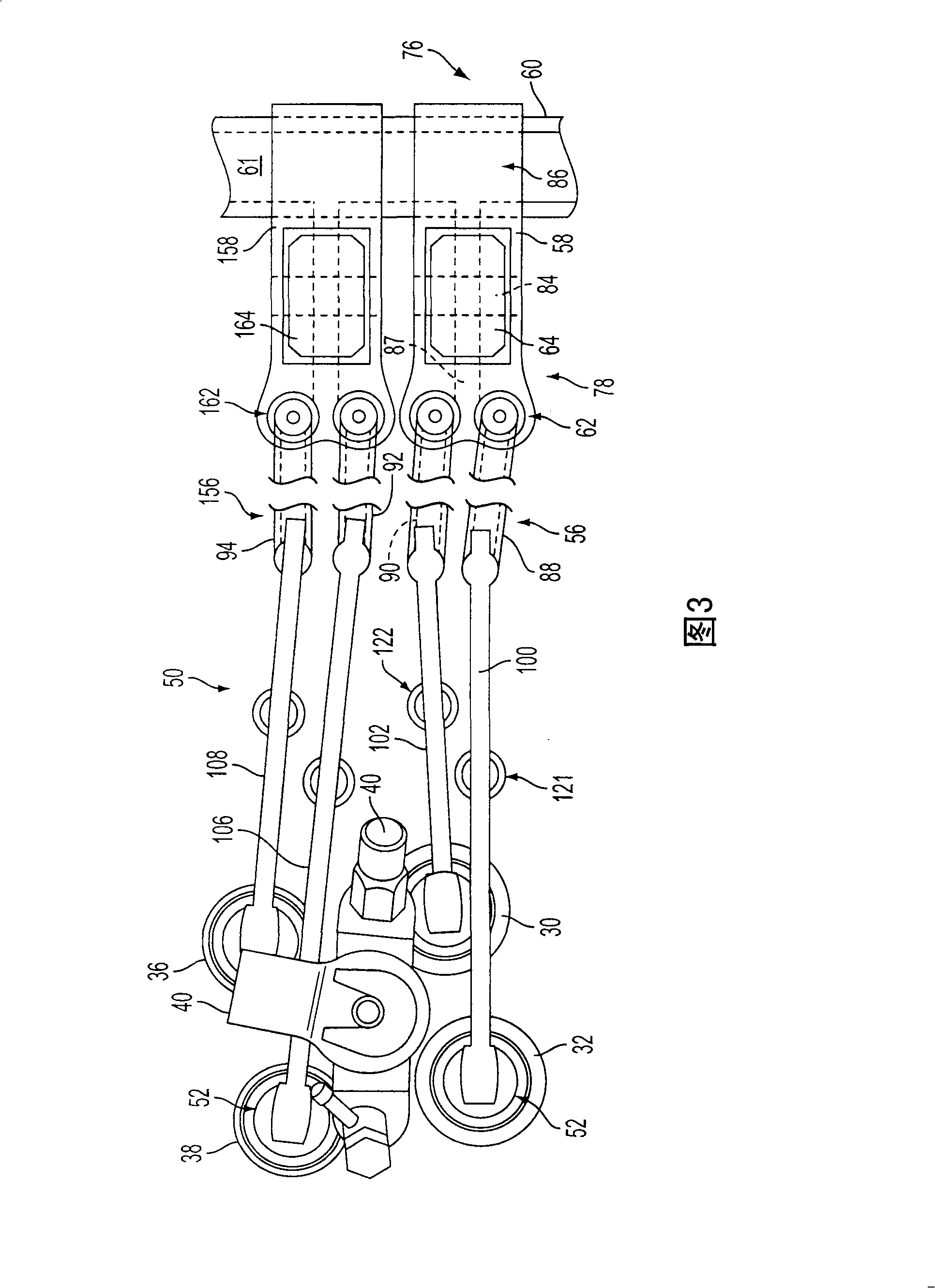

[0015] Those skilled in the art will appreciate that various features of the embodiments shown and described with reference to any one of the figures may be combined with features in one or more other figures to create alternative embodiments not shown or described in detail. . Combinations of the features shown may result in typical embodiments for typical applications. However, various combinations and modifications of the features consistent with the teachings of the present invention may be desired for particular applications or implementations. The exemplary embodiment shown generally relates to a four-stroke, multi-cylinder, direct-injection, compression-ignition internal combustion engine having in-block cam or pushrod valve trains, and while a V-engine configuration is shown, the invention also Can be used in an inline engine configuration. Those skilled in the art will recognize similar applications or implementations in conjunction with other engine / vehicle technol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com