Mechanism for regulating elasticity lining of frequency-changing cyclone compressor

A technology of scroll compressors and regulating mechanisms, which is applied to machines/engines, rotary piston machinery, mechanical equipment, etc., can solve problems such as deterioration of the meshing state, poor overall reliability, and large leakage, and achieve improved meshing reliability and reduced Machining accuracy and the effect of reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

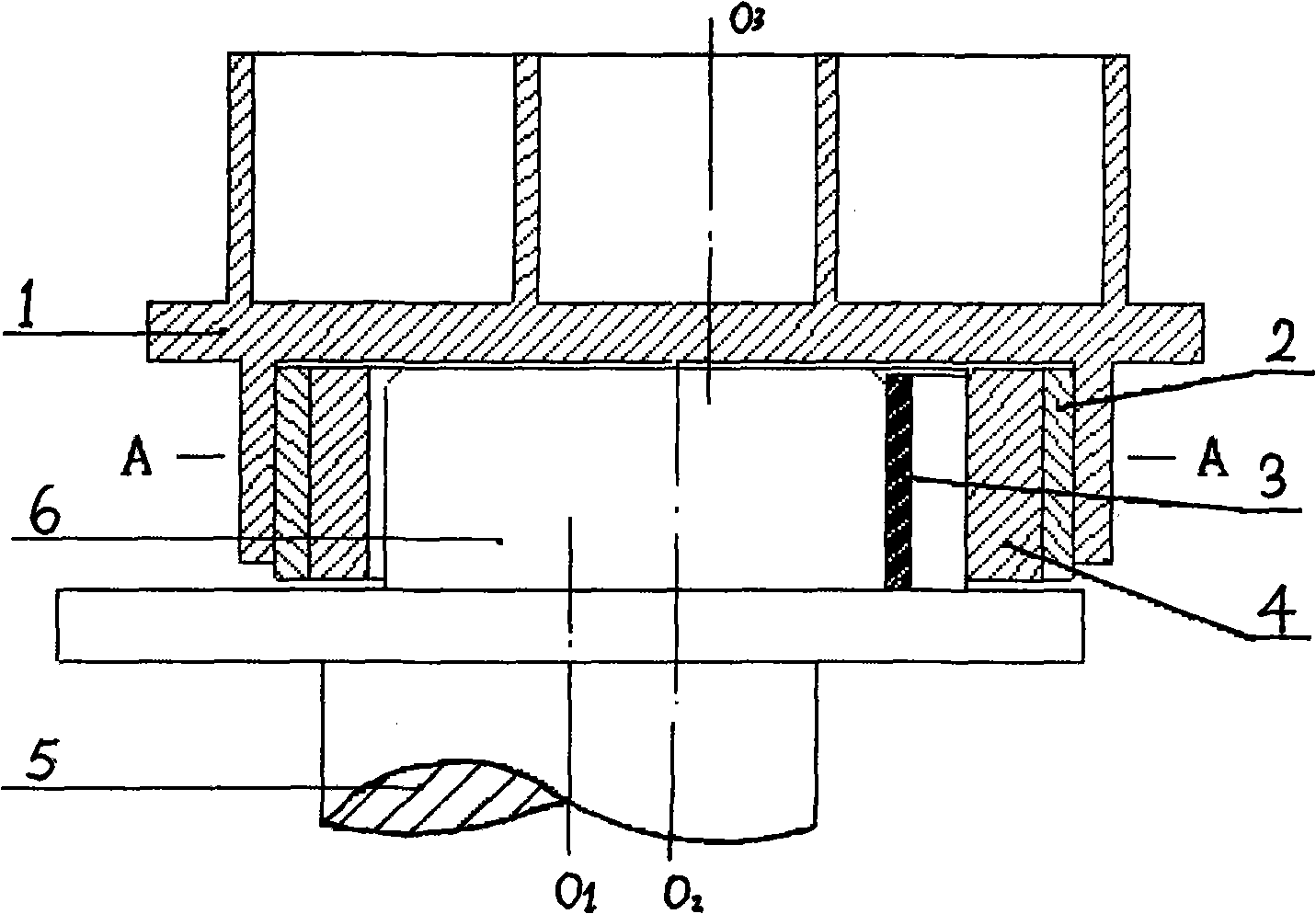

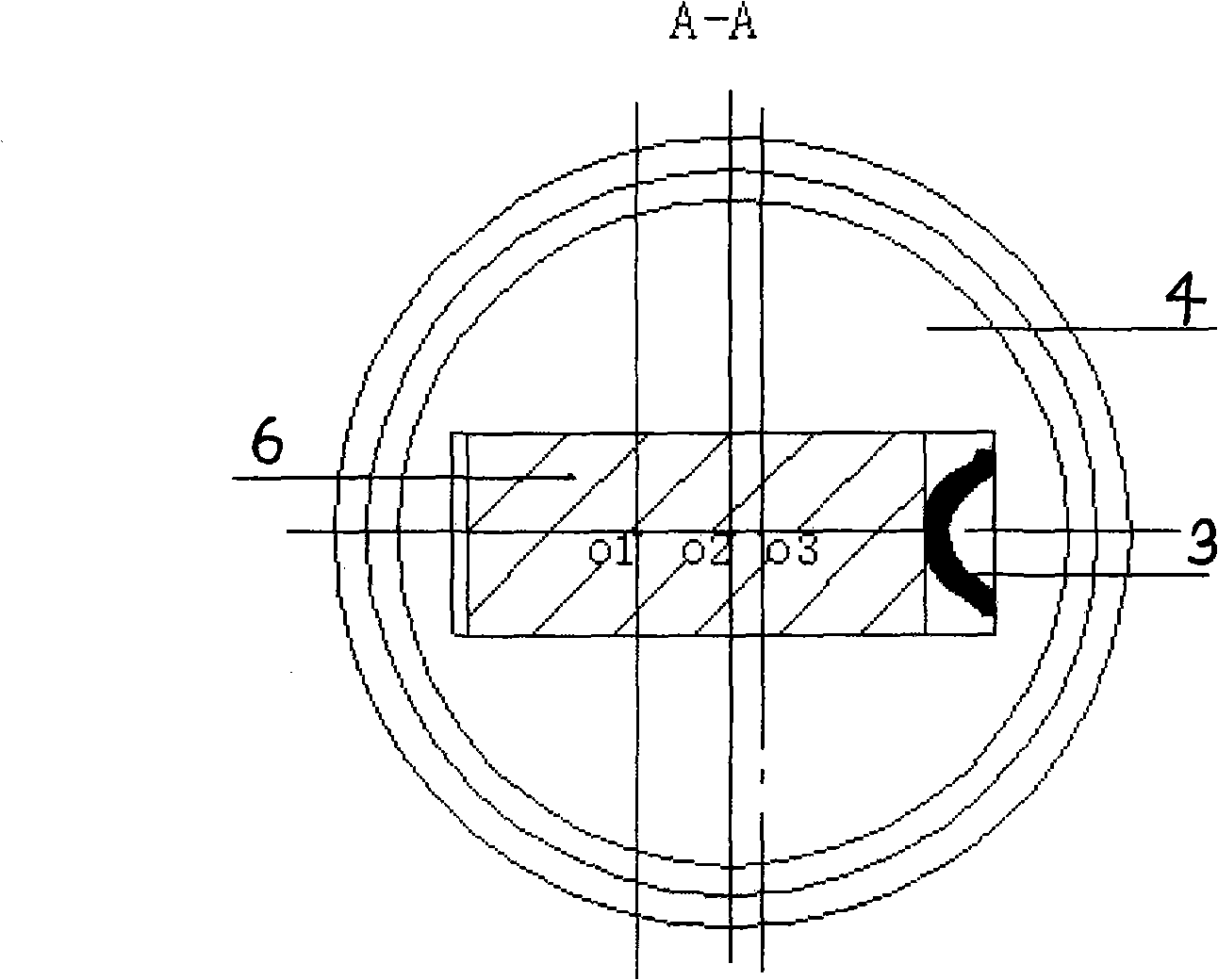

[0016] Such as figure 1 , figure 2 As shown, the elastic bushing 4 is installed on the crank pin 6, the crank pin is connected with the main shaft 5, the sliding bearing 2 is installed on the elastic bushing 4, the moving scroll 1 is installed on the sliding bearing 2, and on the inner surface of the sliding bearing 2 An arc-shaped spring piece 3 is installed between the side plane of the crank pin 6 , and the convex surface of its arc faces the axis O2 of the crank pin 6 . Such as figure 2 As shown, the shape of the cross section of the crank pin 6 is rectangular, and the cross section of the inner hole of the elastic bushing 4 is rectangular. The arc-shaped spring piece 3 is installed on the side close to the axis O3 of the movable scroll 1 on the line connecting the axis O3 of the movable scroll 1 and the axis O2 of the crank pin 6 . The arc plane of the arc-shaped spring piece 3 is symmetrical to the line O2O3 connecting the axis O3 of the movable scroll 1 and the axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com