Straightthrough type double glazing vacuum heat collection tube

A technology of vacuum heat collecting tube and double-layer glass, which is applied to solar heat collectors, solar heat collectors using working fluids, heating devices, etc., can solve the problems that the expansion difference is not easy to eliminate, and achieve easy promotion and simple structural design , The effect of performance safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

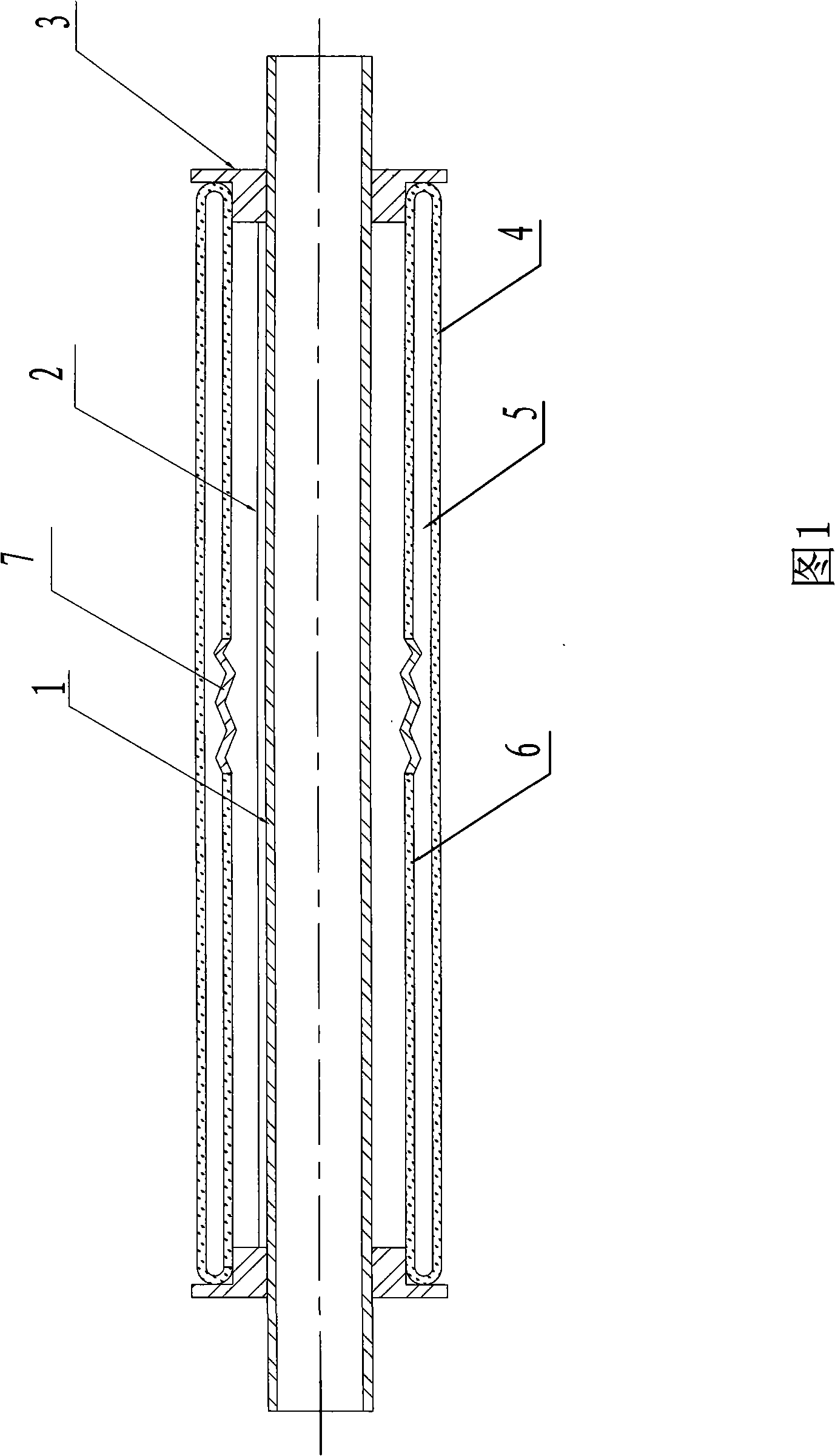

[0021] A kind of double-layer glass straight-through vacuum heat collecting tube as shown in Figure 1, comprises the vacuum bushing that is made up of glass inner tube 6 and glass outer tube 4, is vacuum layer 5 between glass inner tube 6 and glass outer tube 4, described There is also a metal absorption tube 1 inside the vacuum sleeve, and a solar absorbing coating 2 is arranged on the metal absorption tube 1. The metal absorption tube 1 and the vacuum sleeve are sealed and connected by a gasket 3, and the two ends of the glass sleeve are Open your mouth. The metal absorption pipe 1 adopts a straight pipe, and a corrugated pipe 7 is arranged on the glass inner pipe 6 . The set bellows can well eliminate the expansion difference caused by the temperature difference and prevent the pipe burst phenomenon.

Embodiment 2

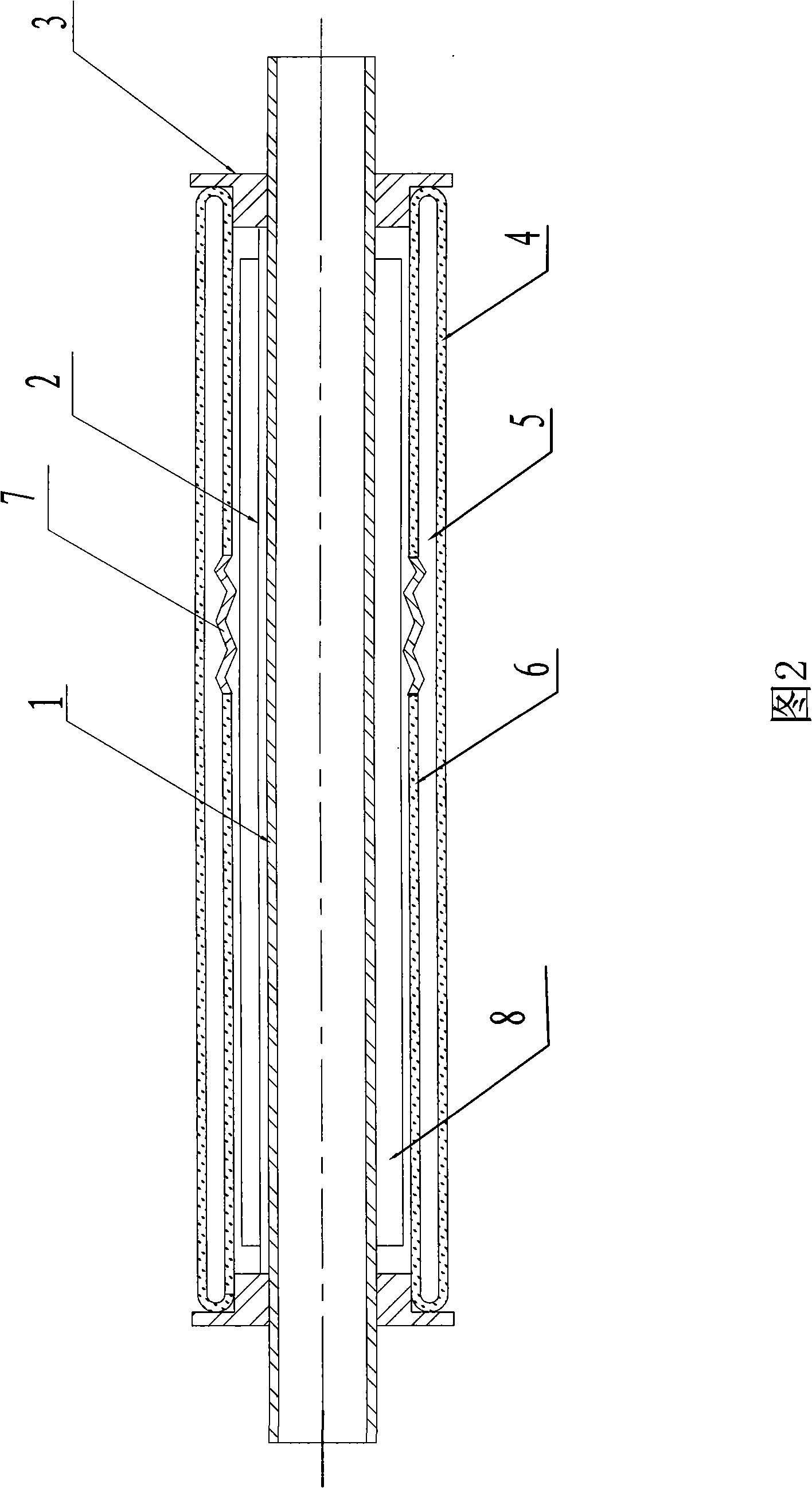

[0023] As shown in Fig. 2, all the other are with embodiment, just also be provided with fin 8 on the metal absorbing tube 1, coating solar absorbing layer on the fin, can increase the effective area of solar absorbing layer like this, can reduce the metal absorbing tube The diameter can effectively reduce the weight of the whole device and make it easier to install.

Embodiment 3

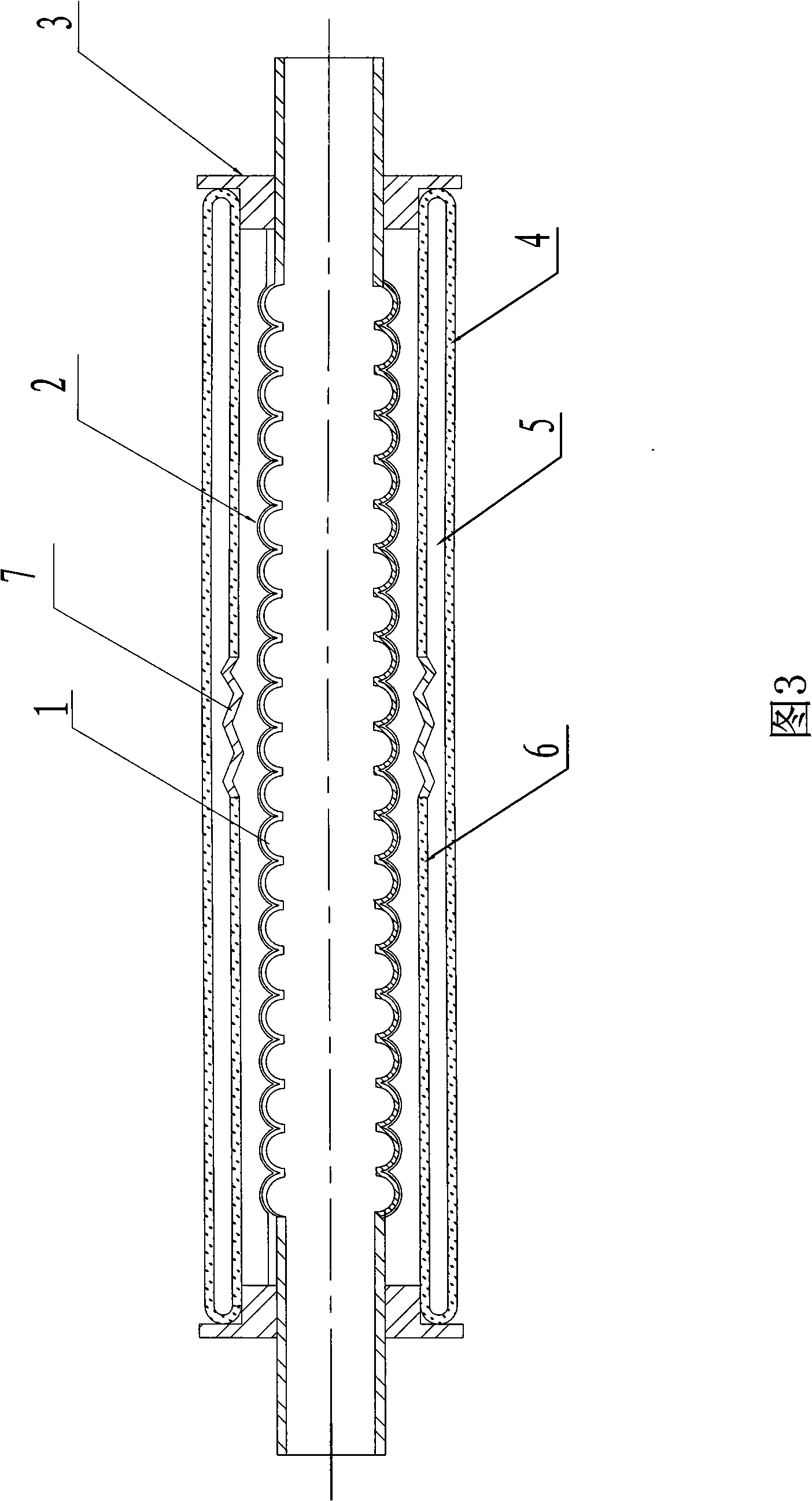

[0025] As shown in Figure 3, the rest is the same as the first embodiment, that is, the metal absorption pipe is replaced by a corrugated pipe from a straight pipe, so that the metal absorption pipe itself can also eliminate part of the expansion caused by the temperature difference.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com