System and method for testing concentricity of lens module

A lens module and detection system technology, applied in the direction of lens position determination, measuring device, testing optical performance, etc., can solve the problems of error, slow speed, low efficiency and precision, etc., improve detection efficiency, reduce production cost, save human effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings.

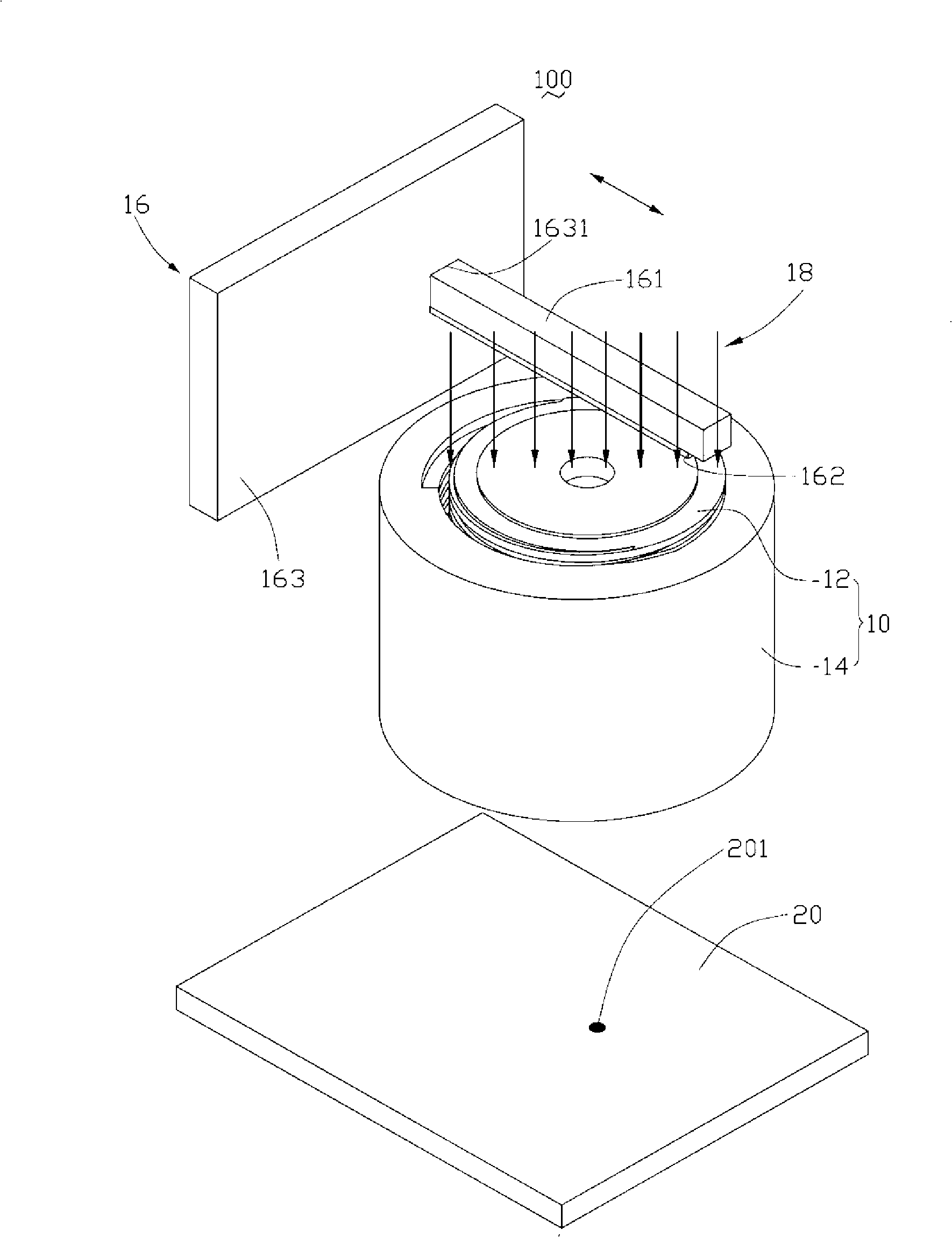

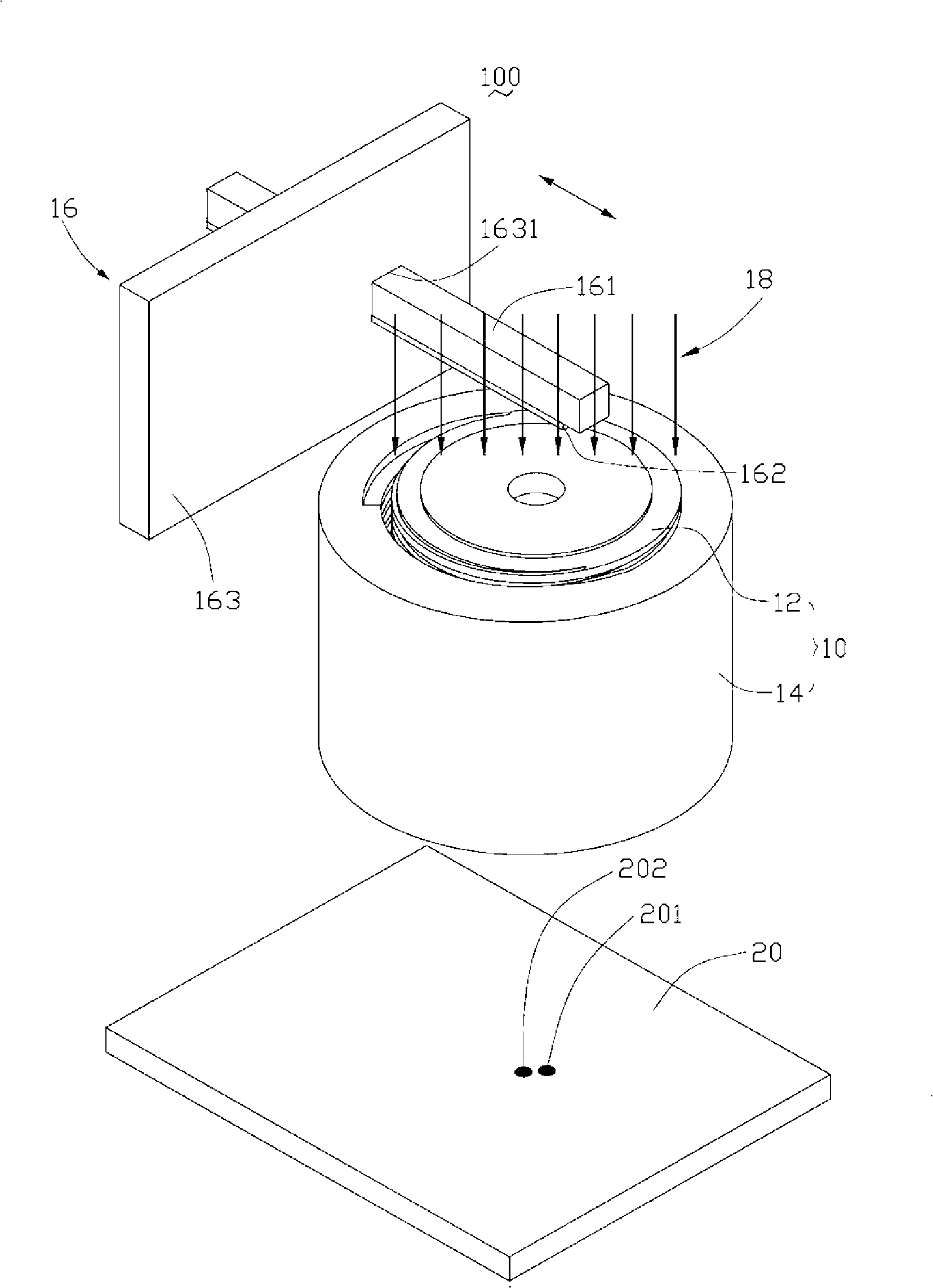

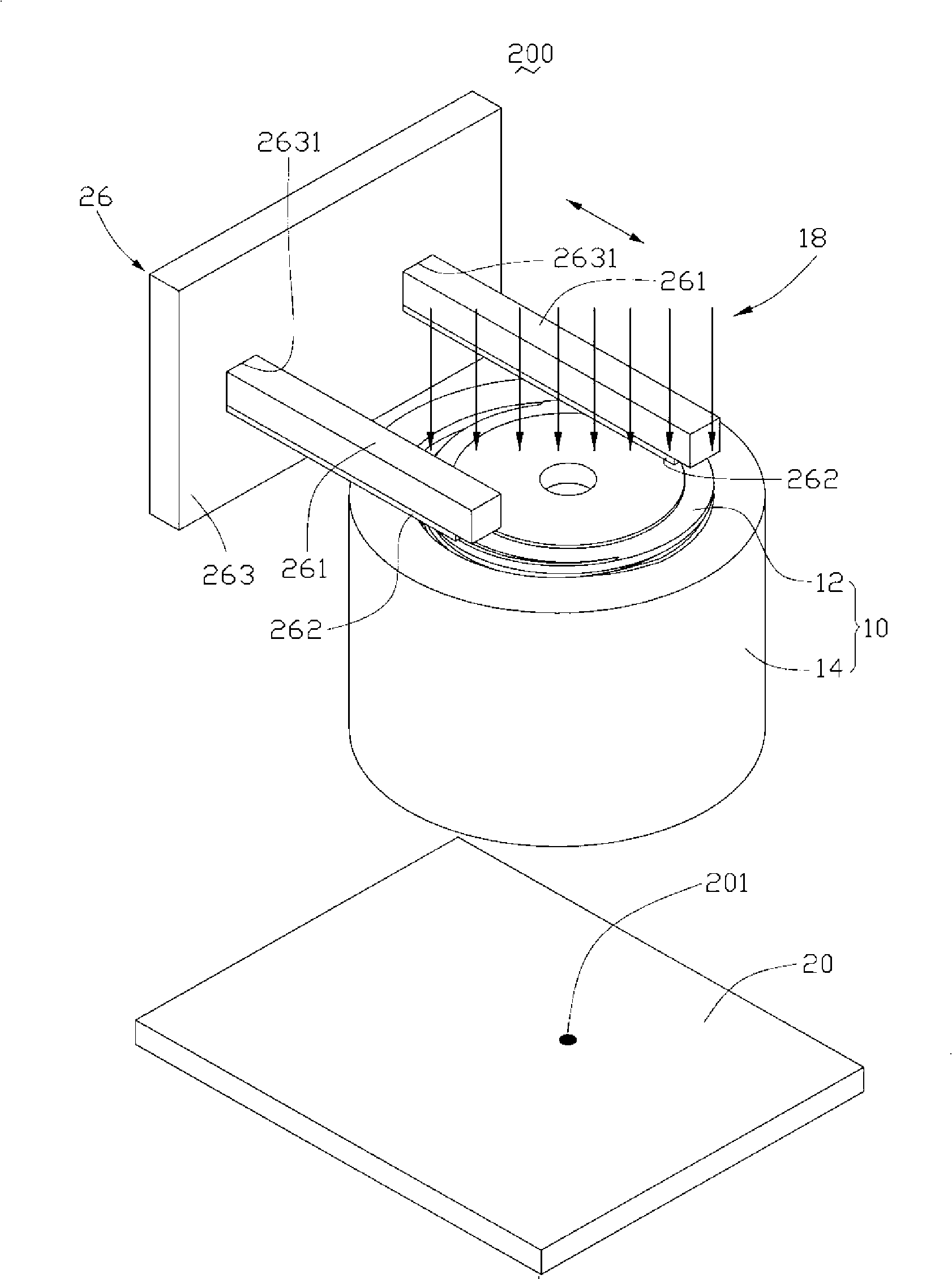

[0014] see figure 1 , is the lens module concentricity detection system 100 according to the first embodiment of the present invention. The lens module concentricity detection system 100 includes a lens barrel rotation driving device 16 , a light source 18 and an optical axis deviation detection device 20 . The detected component in this embodiment is a lens module 10 , which includes a lens barrel 12 and a lens base 14 .

[0015] The lens barrel rotation driving device 16 includes a reciprocating root-type moving rod 161 , a friction block 162 , a moving rod limiting device 163 and a motor (not shown). The reciprocating moving rod 161 is located at one end of the lens module 10 and is in contact with the lens barrel 12 to drive the lens barrel 12 to rotate relative to the lens holder 14. Parameter relationship, specifically, such as the moving length of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com