Method of on-line diagnosis of rift of rolling mill transmission mechanism safety pin

A technology of transmission mechanism and diagnosis method, which is applied in the direction of roll safety equipment, metal rolling, metal rolling, etc., and can solve problems such as rolling mill overturning accidents, rack locking mechanism damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

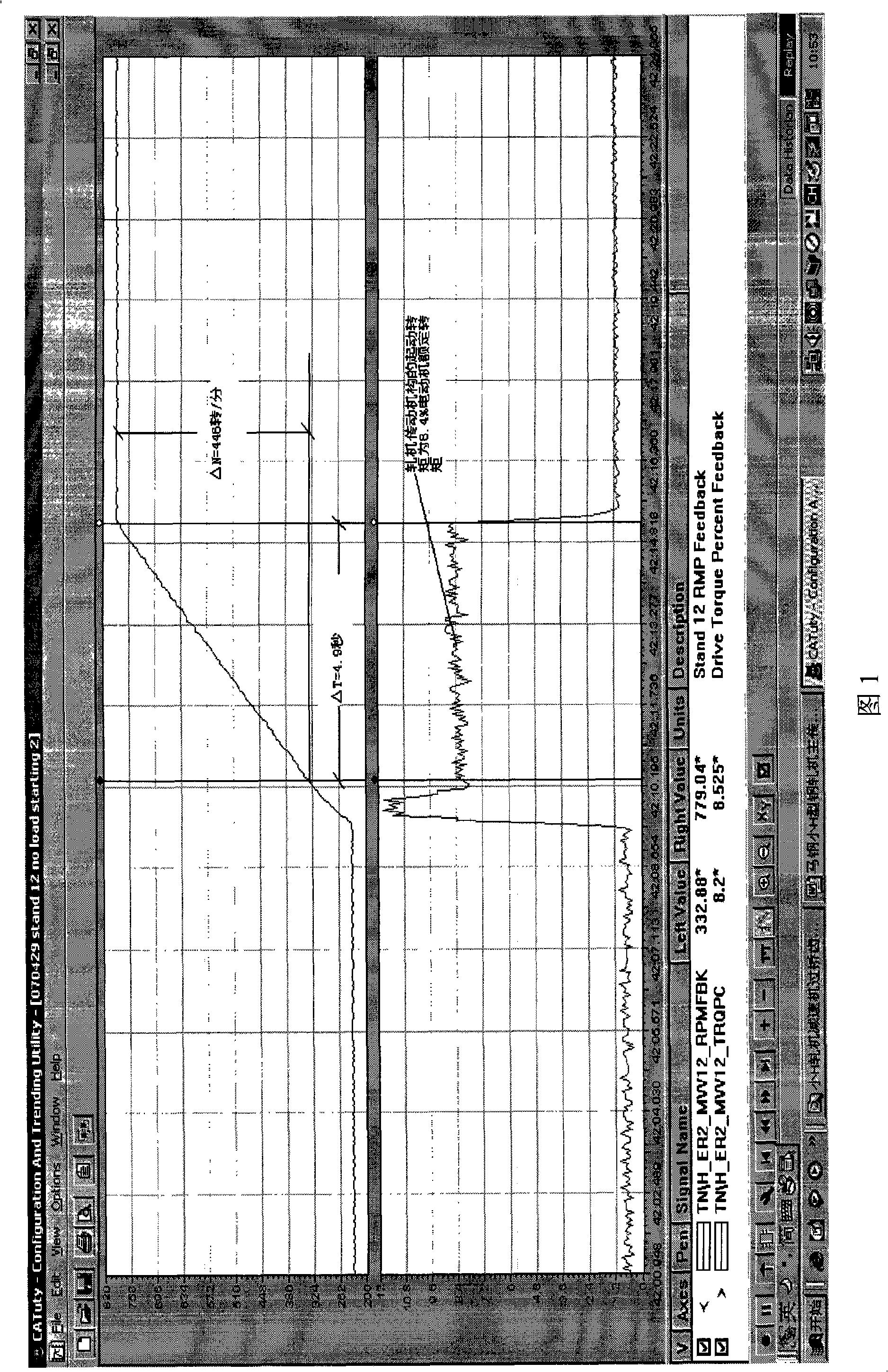

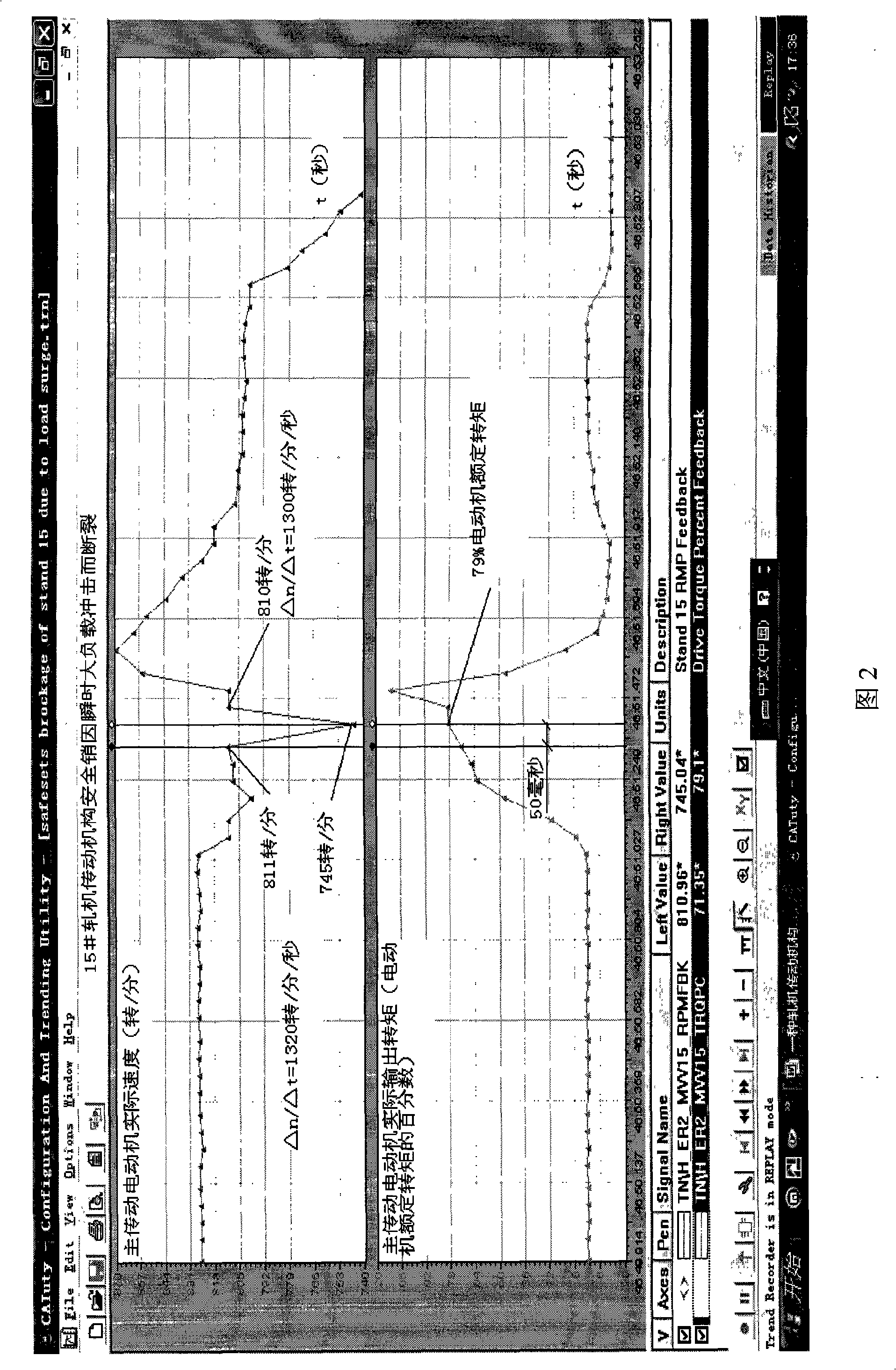

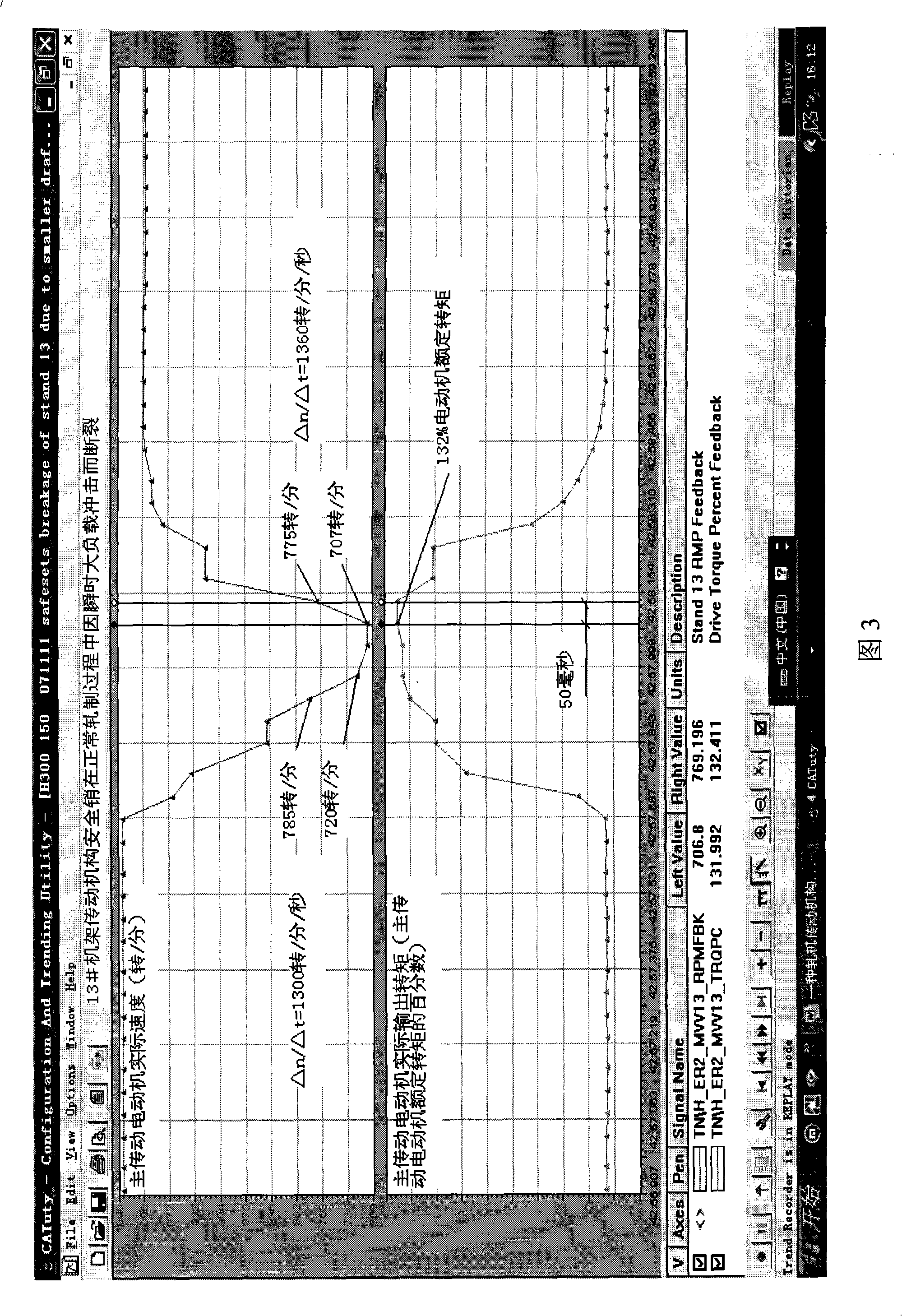

[0032] Now in conjunction with the accompanying drawings, take the small H-shaped steel continuous rolling mill of Maanshan Iron and Steel as an example to specifically illustrate how the present invention is implemented: through the analysis of the safety pin fracture accident of a large number of rolling mill transmission mechanisms of the small H-shaped steel continuous rolling mill: And in the normal rolling process, if the instantaneous impact load of the rolling mill is too large to cause the safety pin of the rolling mill transmission mechanism to break, the instantaneous impact load of the rolling mill is usually within the maximum allowable output torque T of the main drive motor of the rolling mill. dmMore than 1.1 times of that, that is, α=1.1, and after the safety pin breaks, the actual speed of the main drive motor changes from a steep drop to a sharp rise, and its speed increase rate is usually greater than 300 rev / min / s, that is, β=300, However, in the normal pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com