Earthing rotating plough drilling machine

A drilling rig and drilling box technology, which is applied in the field of soil-cultivation rotary plough drilling rigs, can solve the problems of the rotary plough blade being unable to deeply transmit the ploughed land and being easily affected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

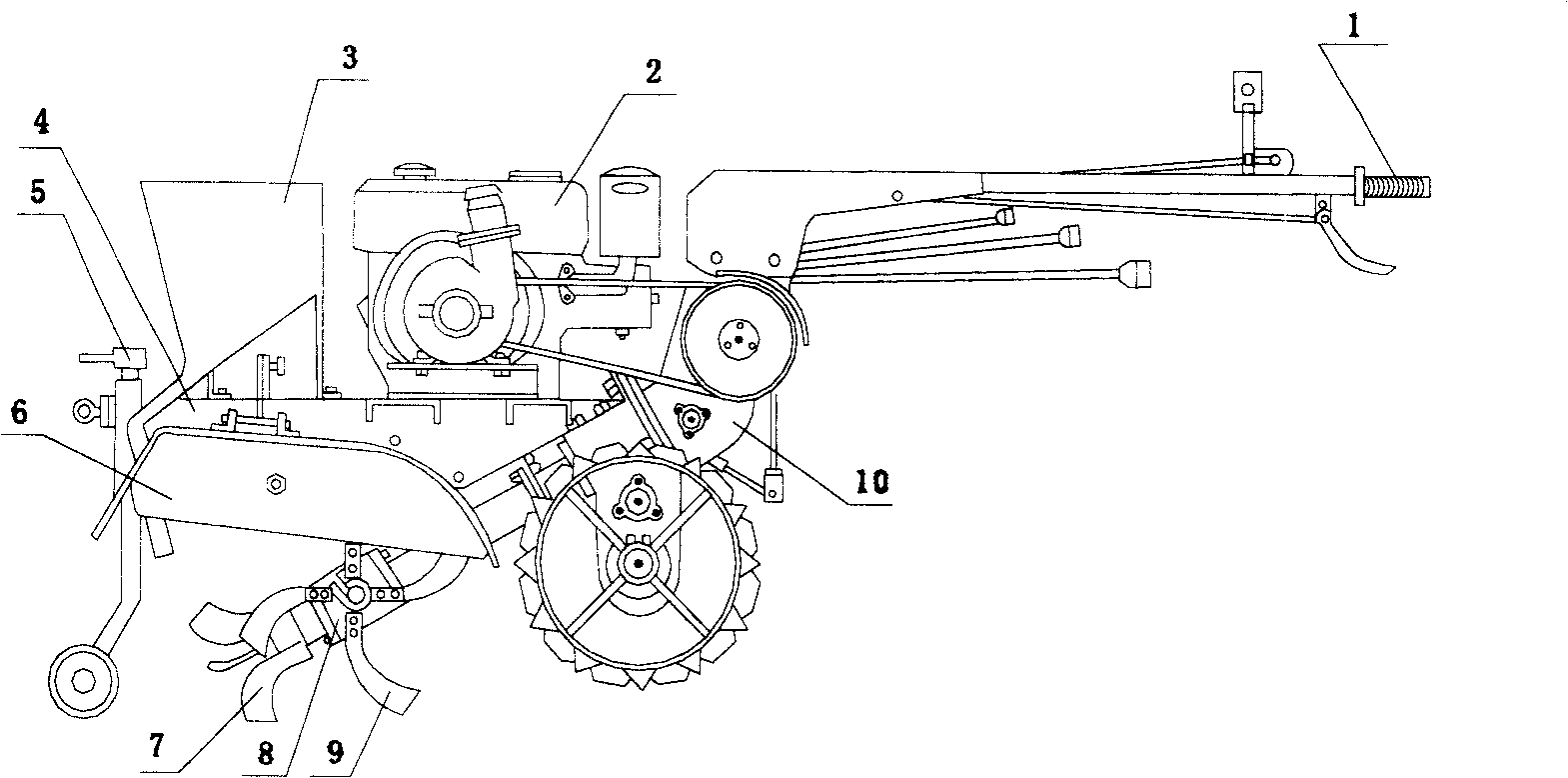

[0019] A rotary plow drilling rig for cultivating soil, comprising a power machine 2 and its power transmission mechanism, a driving wheel and a rotary tillage device. The power machine 2 is arranged on the top of the machine beam 4, a rotary plow drilling box 8 is arranged below the power machine 2, and a universal movable control handle 1 is arranged on the soil-cultivating rotary plow drilling machine, and the rotary tillage device includes a rotary plow drilling box 8 The three-claw leaf drill 7 at the front end and the rotary tiller 9 arranged on both sides of the rotary plow drill case.

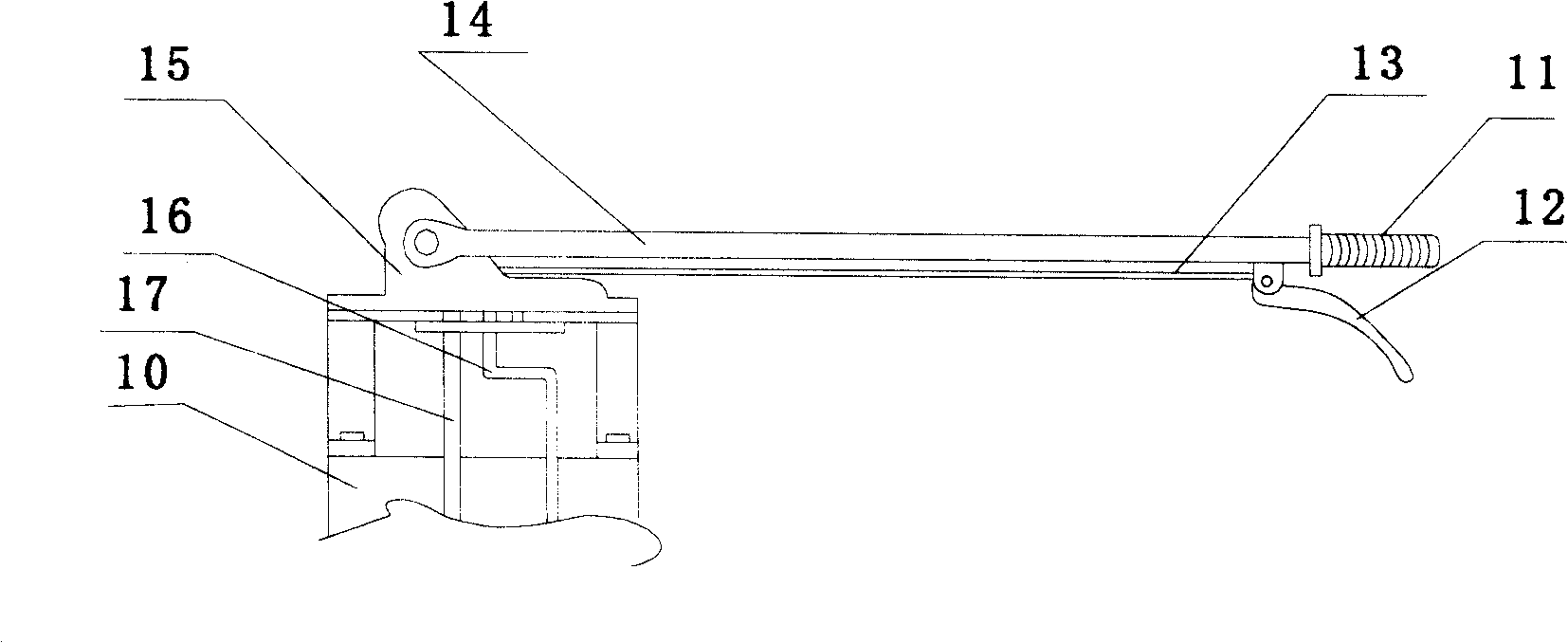

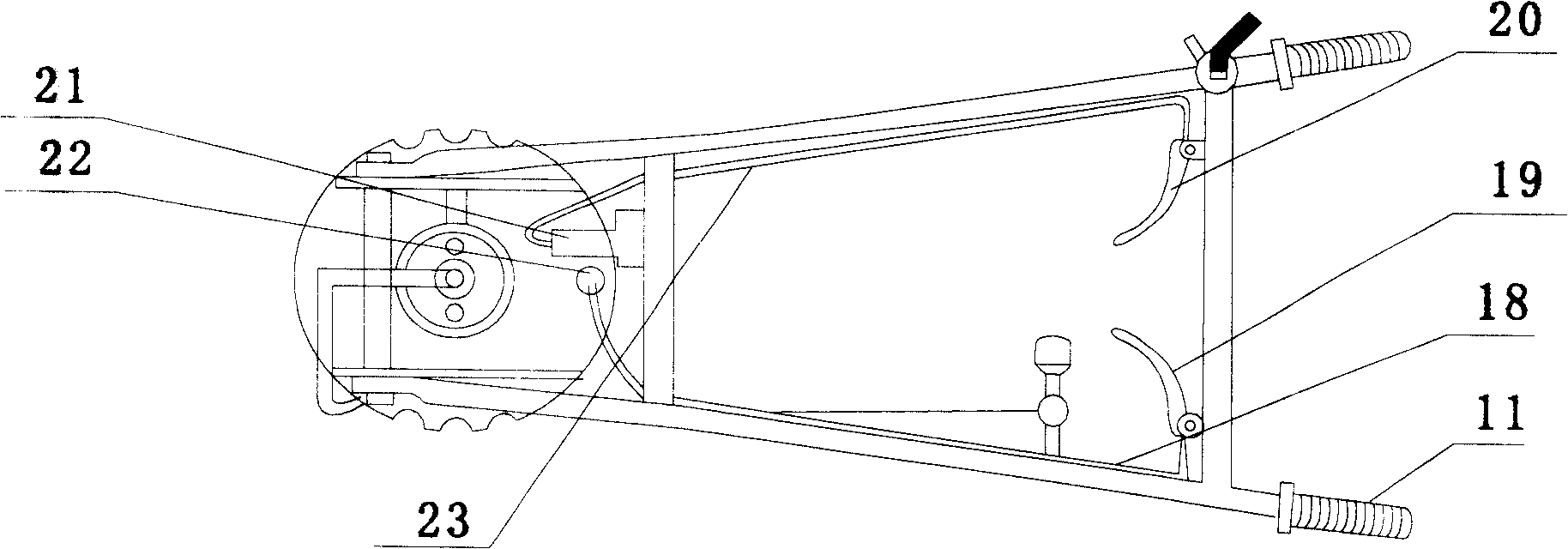

[0020] The universal movable control handle includes a handle 11, an accelerator and clutch control mechanism and a handrail 14. The front end of the handrail 14 is equipped with a turntable 15 connected to the locomotive gearbox 10. A clutch pull rod 17 is arranged in the center of the turntable 15. The clutch There is respectively a steering pull rod 16 on the rotating disk 15 on both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com