Water flow mud-sand separating system for drip irrigation

A separation system, water flow sediment technology, applied to the separation method, filtration separation, sediment separation by centrifugal force, etc., can solve the problems that the separation of sediment can not achieve efficiency and effect, can not use drip tanks, etc., to achieve a stable separation effect, The effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

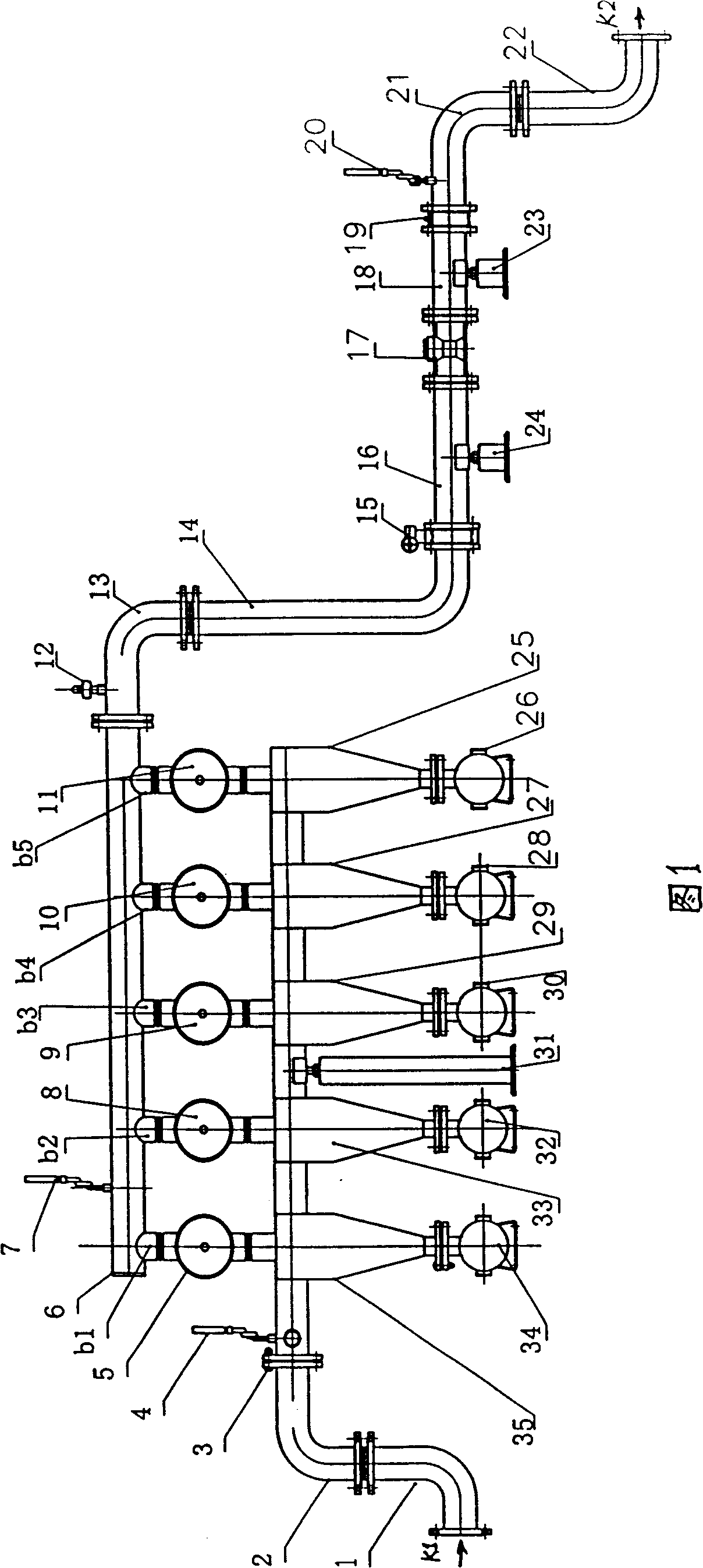

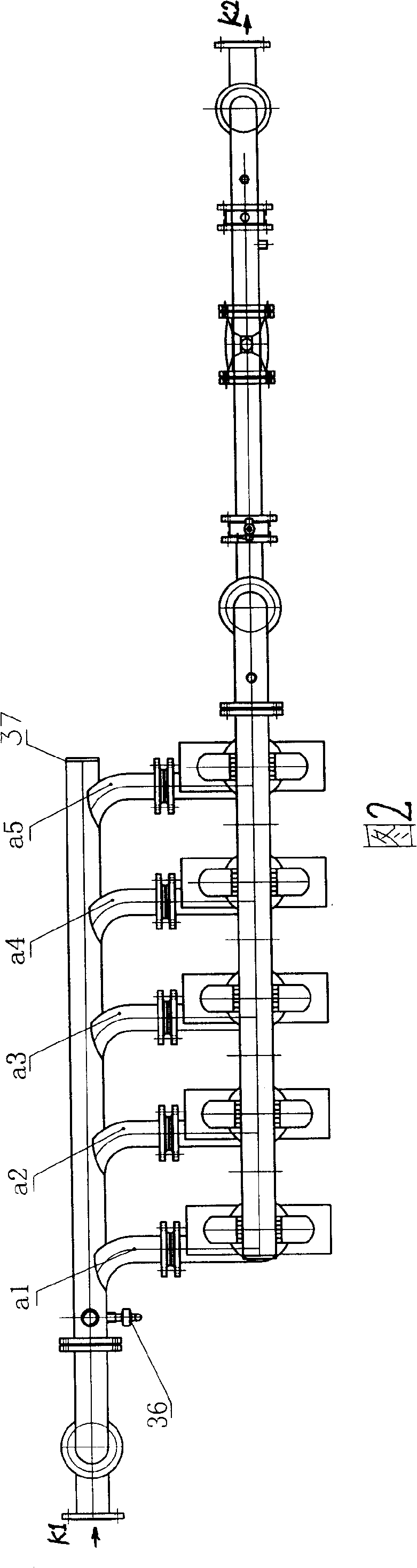

[0008] As shown in Figure 1, the present invention is a kind of water flow sediment separation system that is used for drip irrigation, and the upper part of its cyclone centrifugal separator is a cylinder, and the lower part is a cone, and the sediment outlet at the bottom of the cyclone centrifugal separator is A sand collecting tank is connected, and the water inlet pipe is composed of a first water inlet pipe 1 and a second water inlet pipe 2 . As shown in Figure 2, the second water inlet pipe 2 is connected to the water distribution pipe 37 through the flange 3, and the first water distribution pipe a1, the second distribution pipe a2, and the third water distribution pipe 37 are respectively equipped with five water splitting pipes. The pipe a3, the fourth branch pipe a4, and the fifth branch pipe a5, the water inlet of each branch pipe are installed on the water branch pipe 37 obliquely relative to the flow direction of the water inlet, and the water inlet of the first b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com