Gas-liquid-solid three-phase separator

A three-phase separator, gas-liquid-solid technology, applied in the separation method, dispersed particle separation, sediment separation by centrifugal force, etc., can solve the problems of large separator volume, poor gas separation effect, complex internal structure, etc., to achieve separation High efficiency, convenient operation and maintenance, and solve the effect of high equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing:

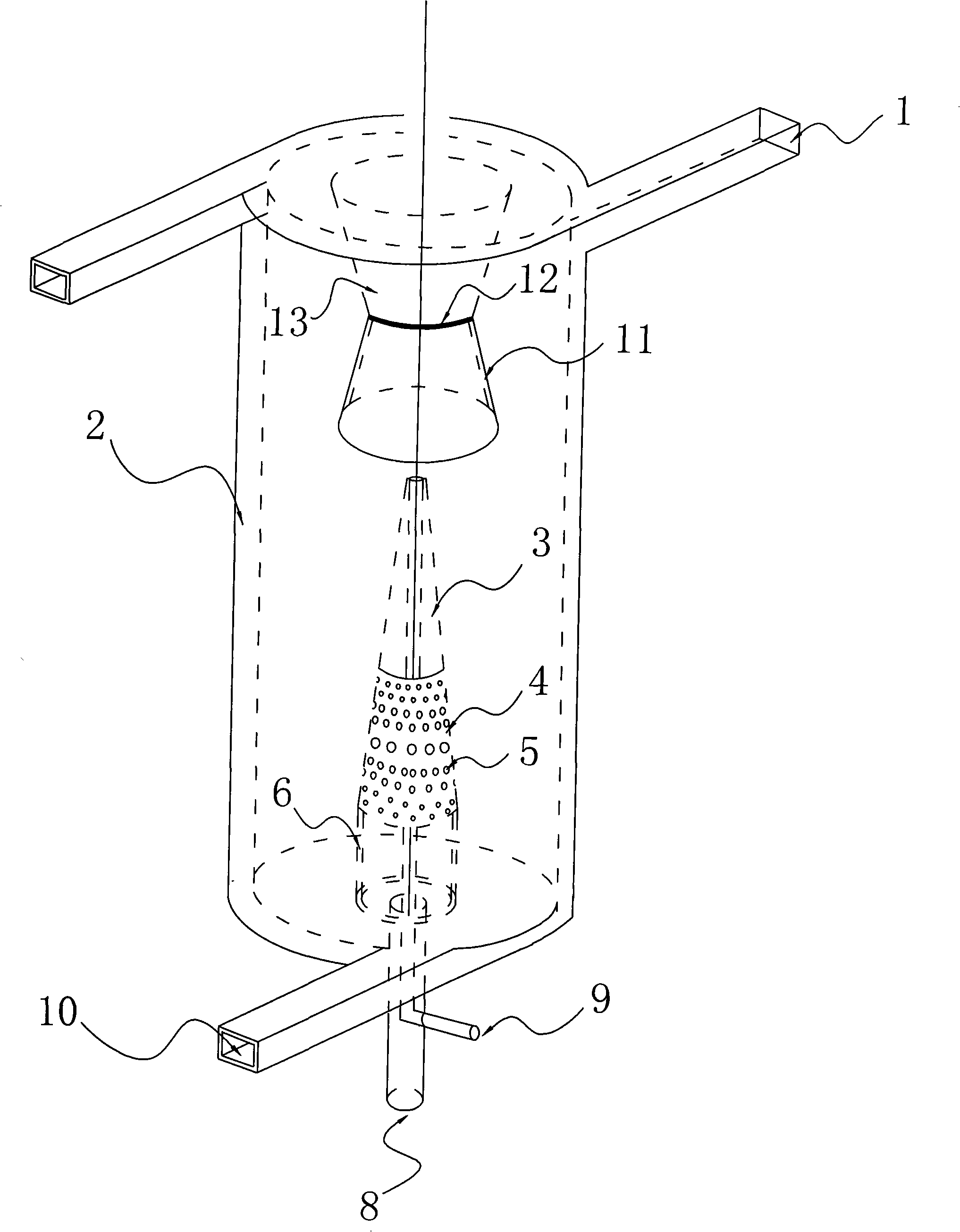

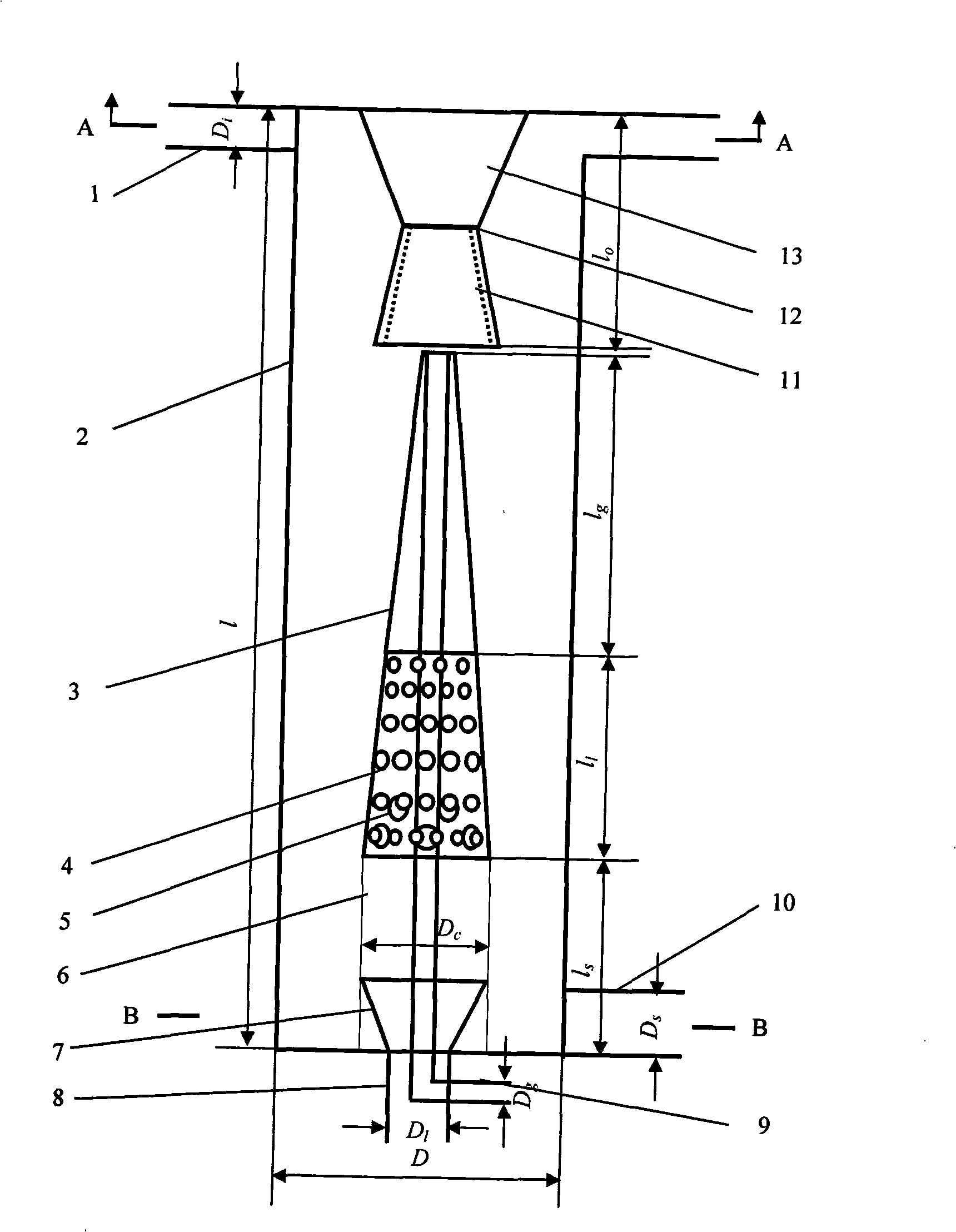

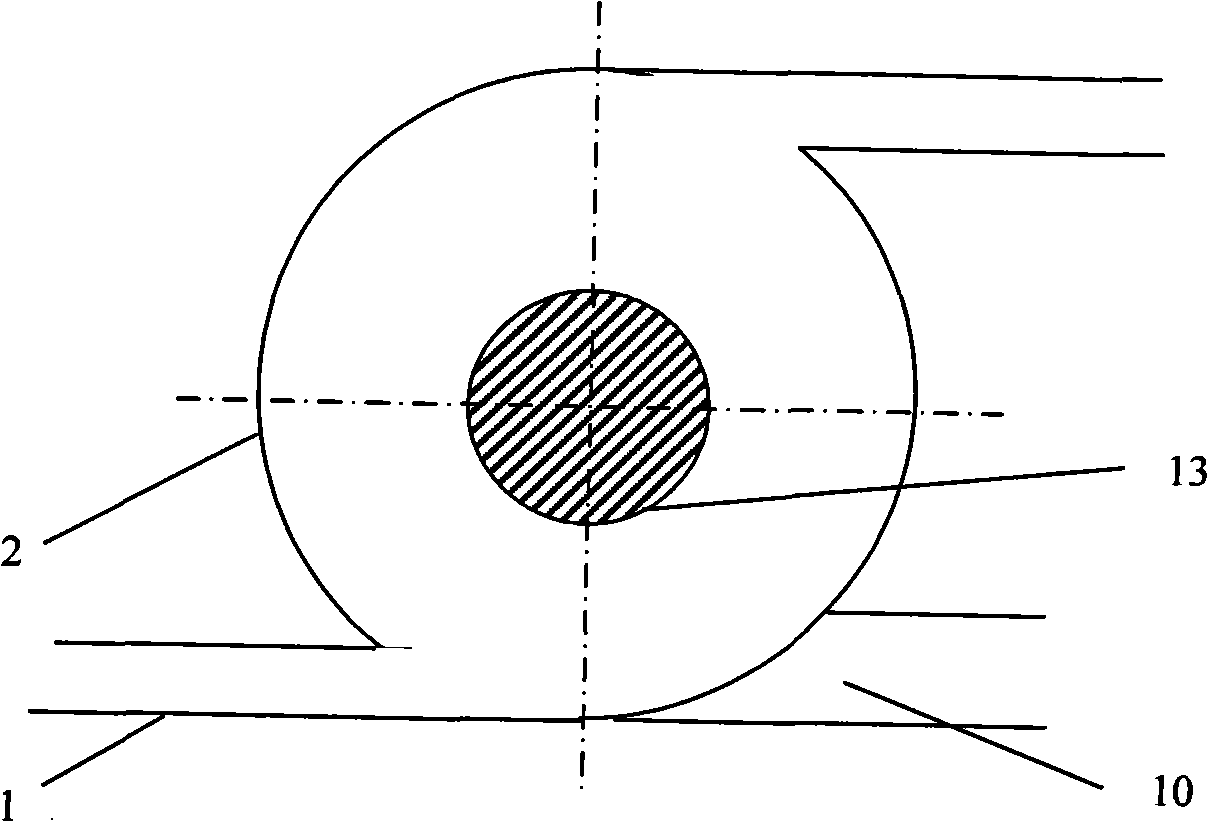

[0013] Gas, liquid and solid three-phase separator described in the present invention, its structure is as follows figure 1 As shown, the main body is a separation cylinder 2 with a symmetrical tangential inlet pipe 1 at the top. The top surface of the separation cylinder 2 is closed, and a hammer-shaped body is fixed at the center of its inner surface. The upper part of the hammer-shaped body is a top cone 13. As the connection end with the inner surface of the separation cylinder, the lower part is a hollow expansion section 11, and the two parts are separated by a baffle plate 12. The bottom end surface of the separation cylinder 2 is closed, and a sand discharge pipe 10 is opened along the tangential direction, and a liquid discharge pipe 8 is opened along the central axis direction. The liquid section 6, the liquid collection section 4 with the liquid collection hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com