Pipeline crack far-field vortex checking method

A detection method, far-field eddy current technology, applied to pipeline systems, measuring devices, instruments, etc., can solve problems such as detection, analysis and discussion of axial cracks in pipelines without ferromagnetic materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

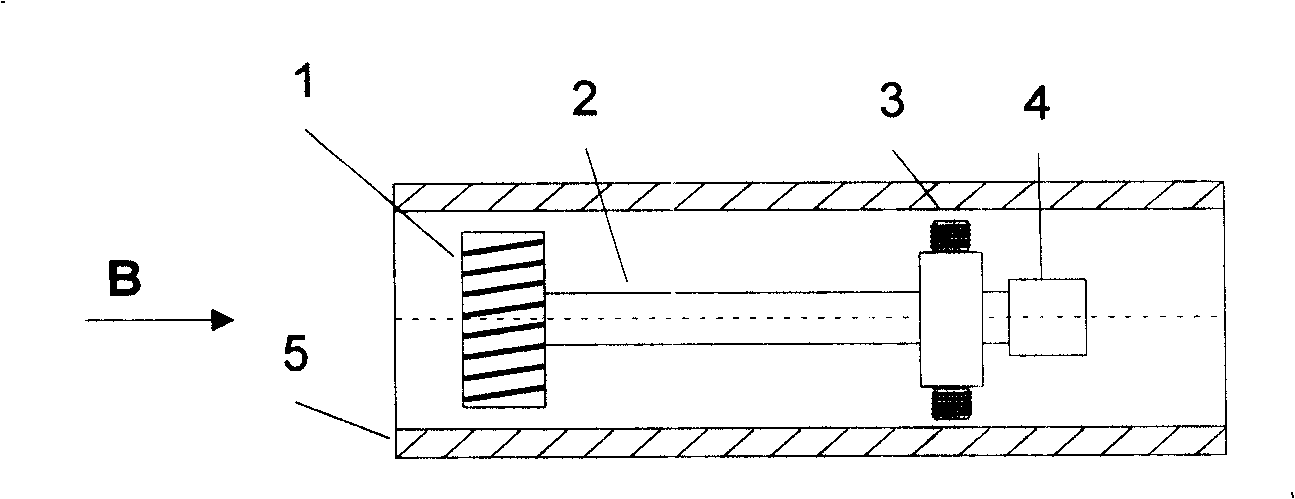

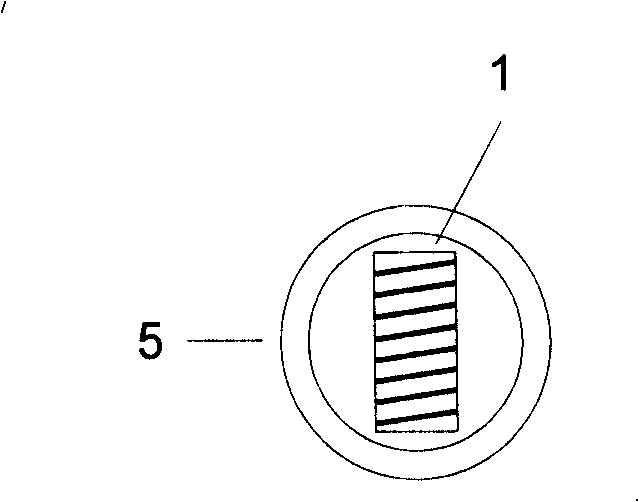

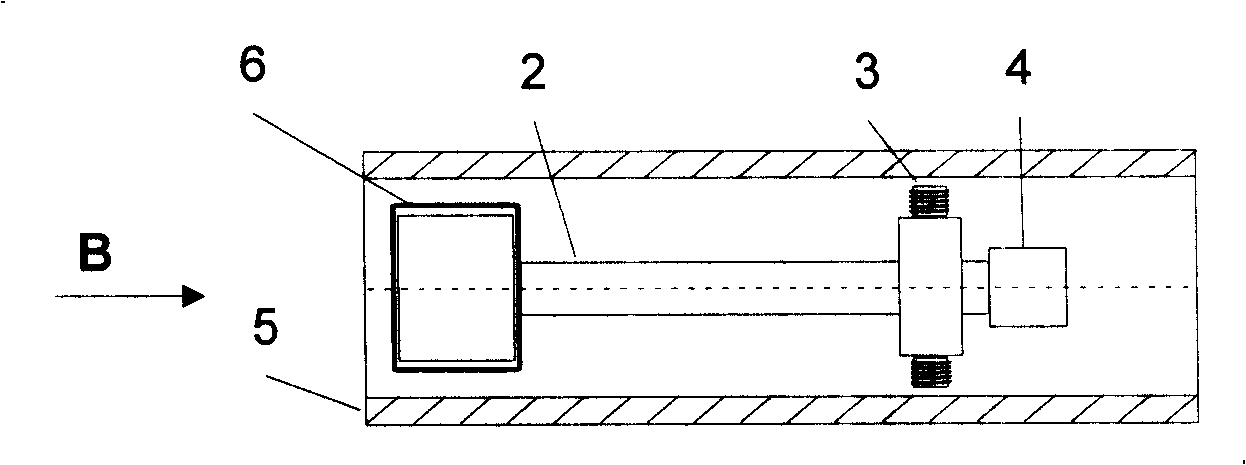

[0026] The technical scheme and implementation of the far-field eddy current detection of pipeline axial cracks involved in the present invention will be further described in conjunction with the accompanying drawings.

[0027] The present invention proposes two far-field eddy current methods based on the same circumferential excitation technology:

[0028] The first method uses the pipe radial excitation coil 1 to replace the coaxial excitation coil used in the original far-field eddy current probe, and passes a low-frequency (20 to 10000 Hz) AC current into the radial excitation coil, and the alternating magnetic field distribution caused by the AC current In the circumferential direction of the cross section of the pipe 5 . Similar to the working principle of the traditional far-field eddy current, the alternating magnetic field induces the eddy current, and radially excites the tube wall near the coil as part of the indirect coupling energy path.

[0029] In the far-field...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com