Rotary proton exchange film fuel battery

A proton exchange membrane and fuel cell technology, applied in fuel cells, solid electrolyte fuel cells, fuel cell components, etc., can solve the problems of difficulty in achieving uniform humidity adjustment, difficulty in uniformly discharging heat, and low power density. The effect of high membrane electrode utilization, reduced difficulty, and high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In the following specific embodiments of the spinning disk type proton exchange membrane fuel cell, it is assumed that the anode reaction gas is hydrogen, and the cathode reaction gas is air.

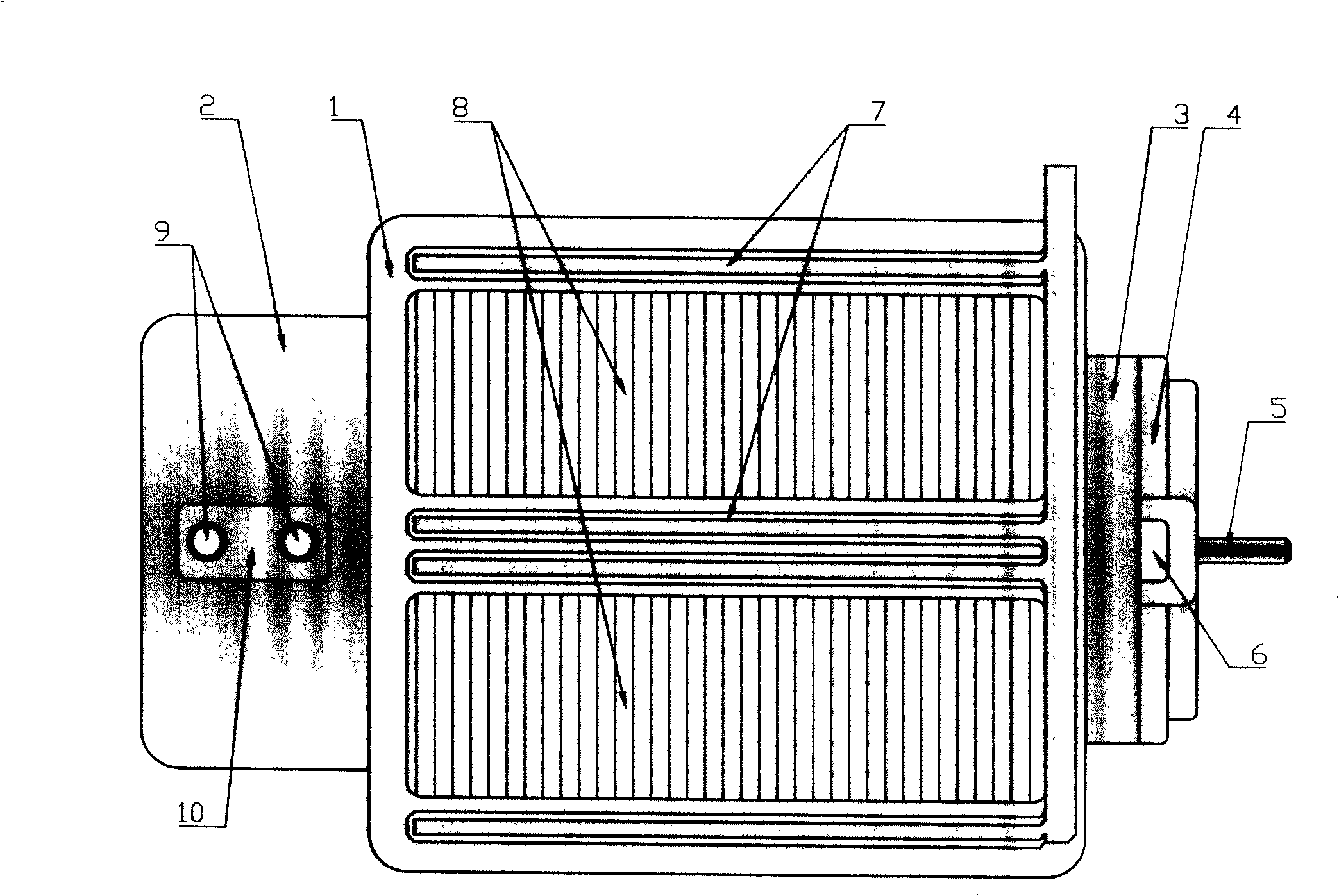

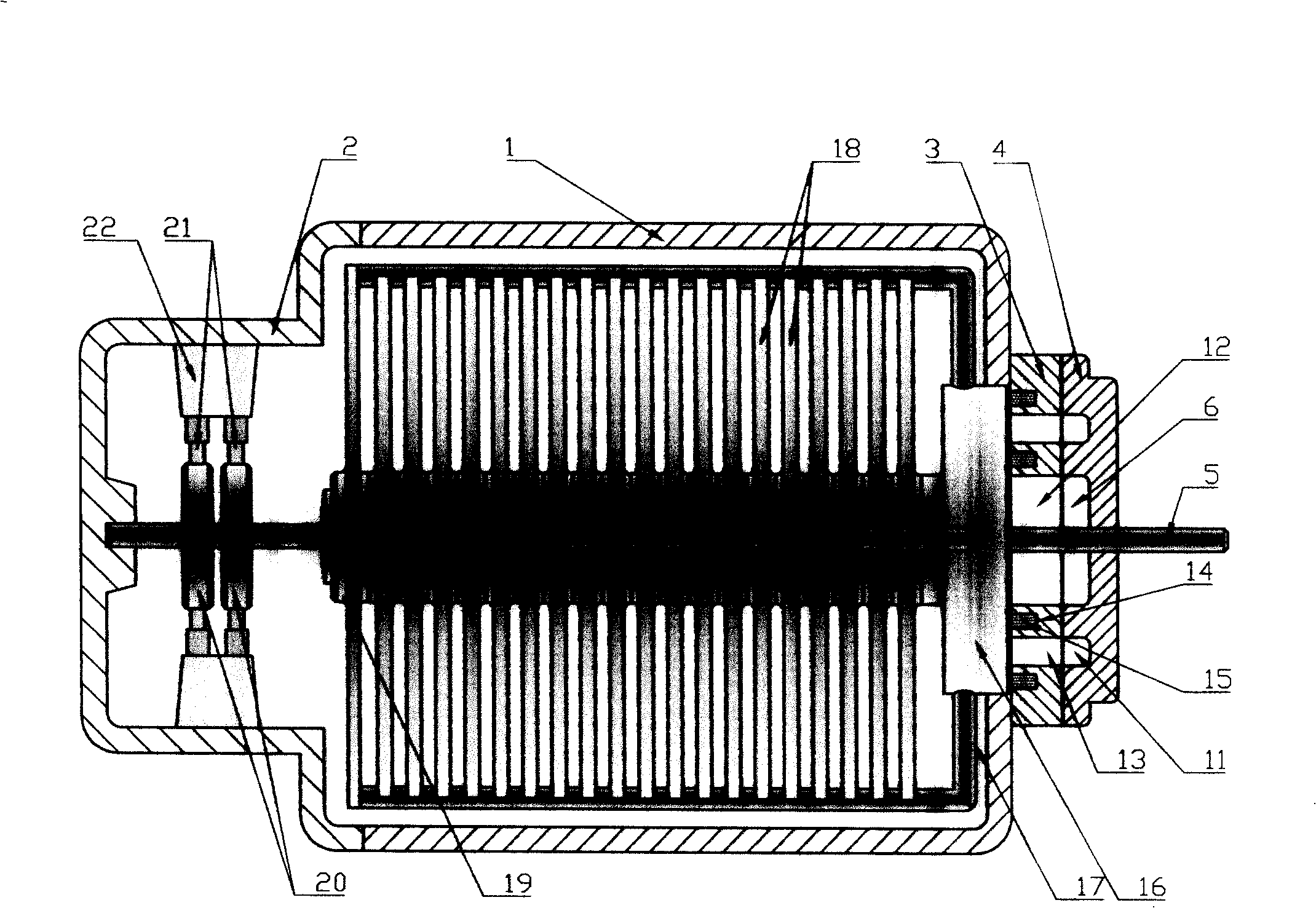

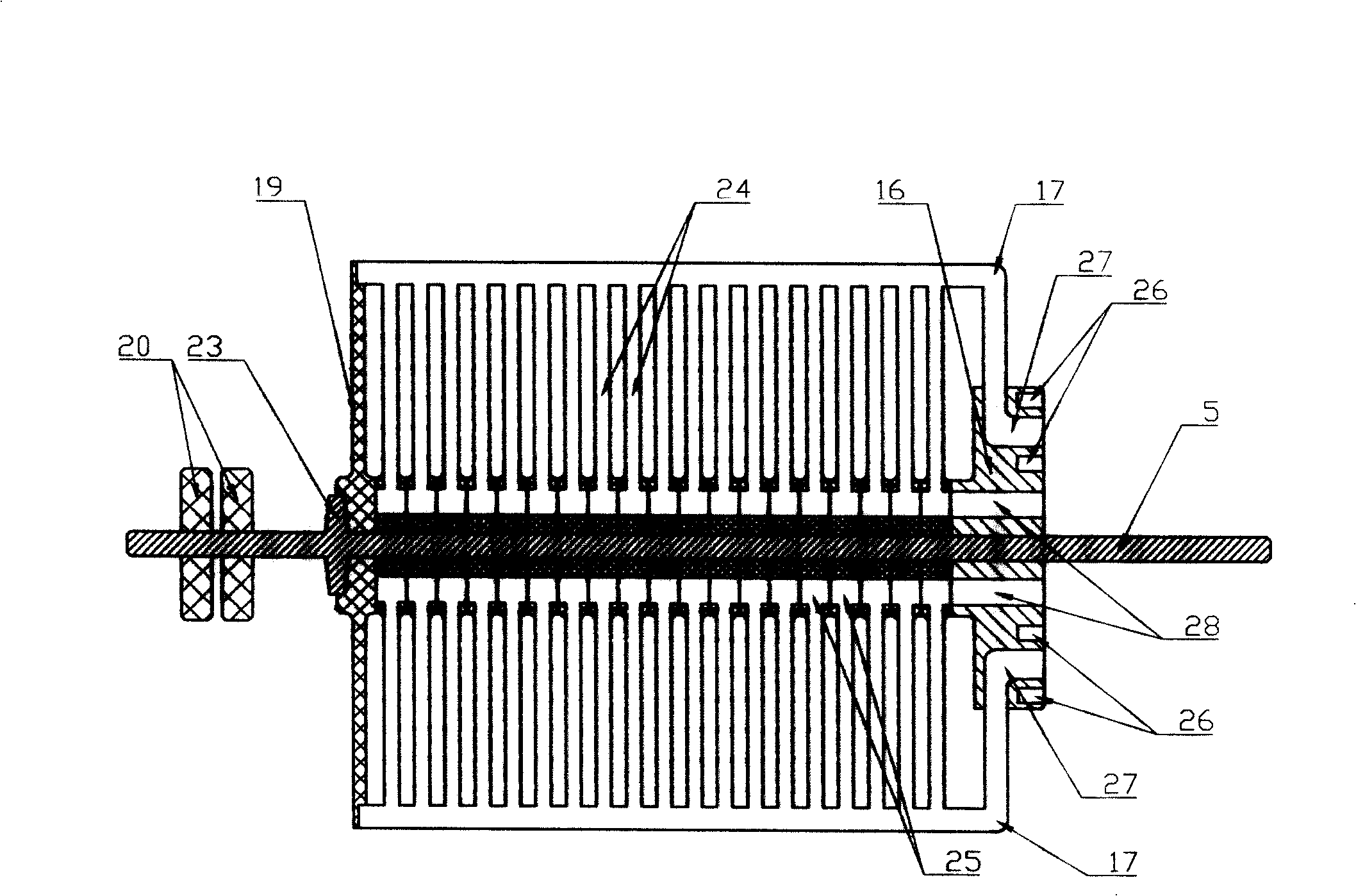

[0031] from figure 1 The base 1 of the rotary disk type proton exchange membrane fuel cell can be seen in the figure, the rear end cover 2, the terminal post seat 10 installed on the rear end cover and the terminal post 9 for leading out the current thereon. Obviously, any other conductive element suitable for making a circuit can be used instead of this terminal. Visible on the support 1 are several water supply pipes 7 that supply water to the spraying device in the support, and the vent 8 of the air supply device. It should be pointed out that in order to improve the air supply efficiency, the relative movement between the air and the rotary disc can be used to reduce the required power of the air supply device, that is, figure 1 The air circulation direction of the upper an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com