Winding frame with monitored secondary travel

A winding machine, the first technology, applied in the direction of thin material processing, conveying filamentous materials, transportation and packaging, etc., can solve the problem of unsuitable winding performance and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

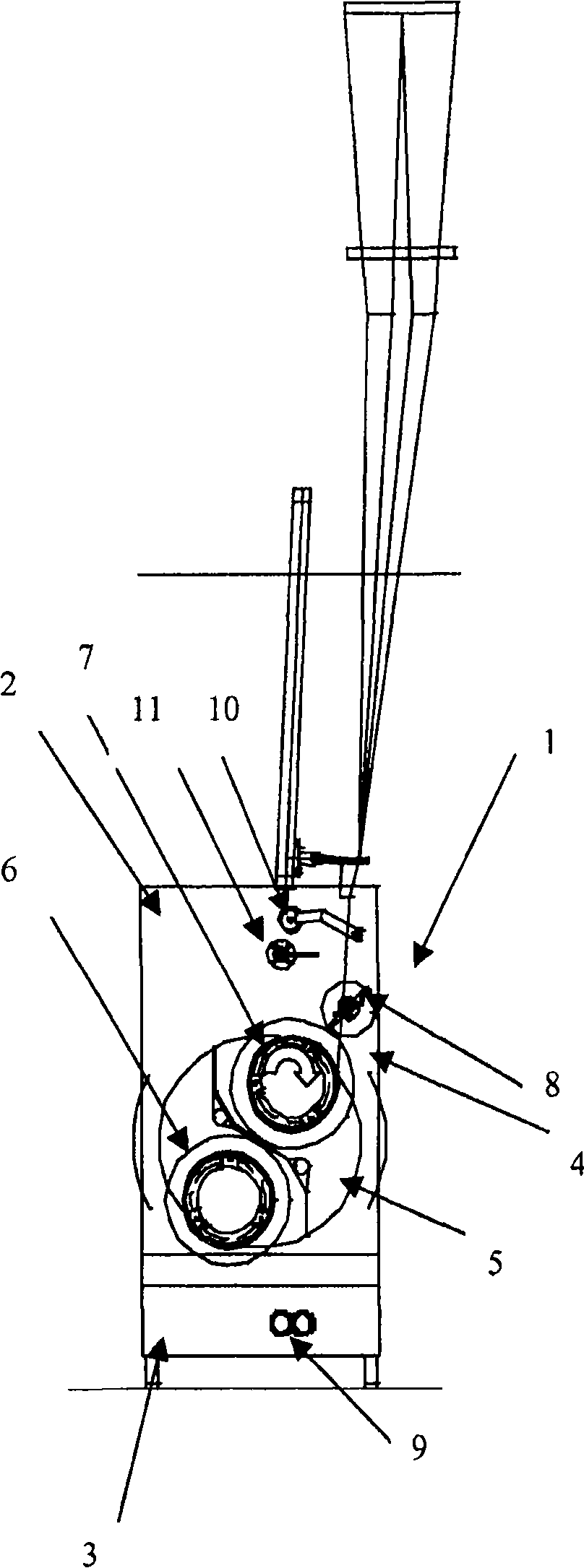

[0044] The best embodiment of the winding machine 1 according to the invention is in figure 1 As shown in , the winding machine comprises a metal chassis 2 obtained by the technique of mechanical welding of preprocessed mechanical components or metal components defined in commercial standards. The underframe 2 mainly comprises a substantially rectangular base 3 arranged on rationally arranged feet arranged to correspond to the configuration or distance of the forks of a forklift or similar handling equipment, so as to facilitate The winder is inserted into the drawing position.

[0045] On the base, in the housing part, is mounted a closure structure 4 designed to house all the components necessary for the functioning of the winding machine 1 . To this end, in a non-limiting manner, the cabinet-shaped enclosure has the management and command means required to control the different mechanisms that will be described later in this description.

[0046]Wire, hydraulic, electric,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com