Rolling bearing, spindle support structure of main motor for railway vehicle, and bearing structure

A rolling bearing and bearing technology, applied in the field of rolling bearings, can solve the problems of abnormal heat generation, insufficient holding force and high consistency, and achieve the effects of extending the maintenance period, preventing grease bias and excellent lubricating performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

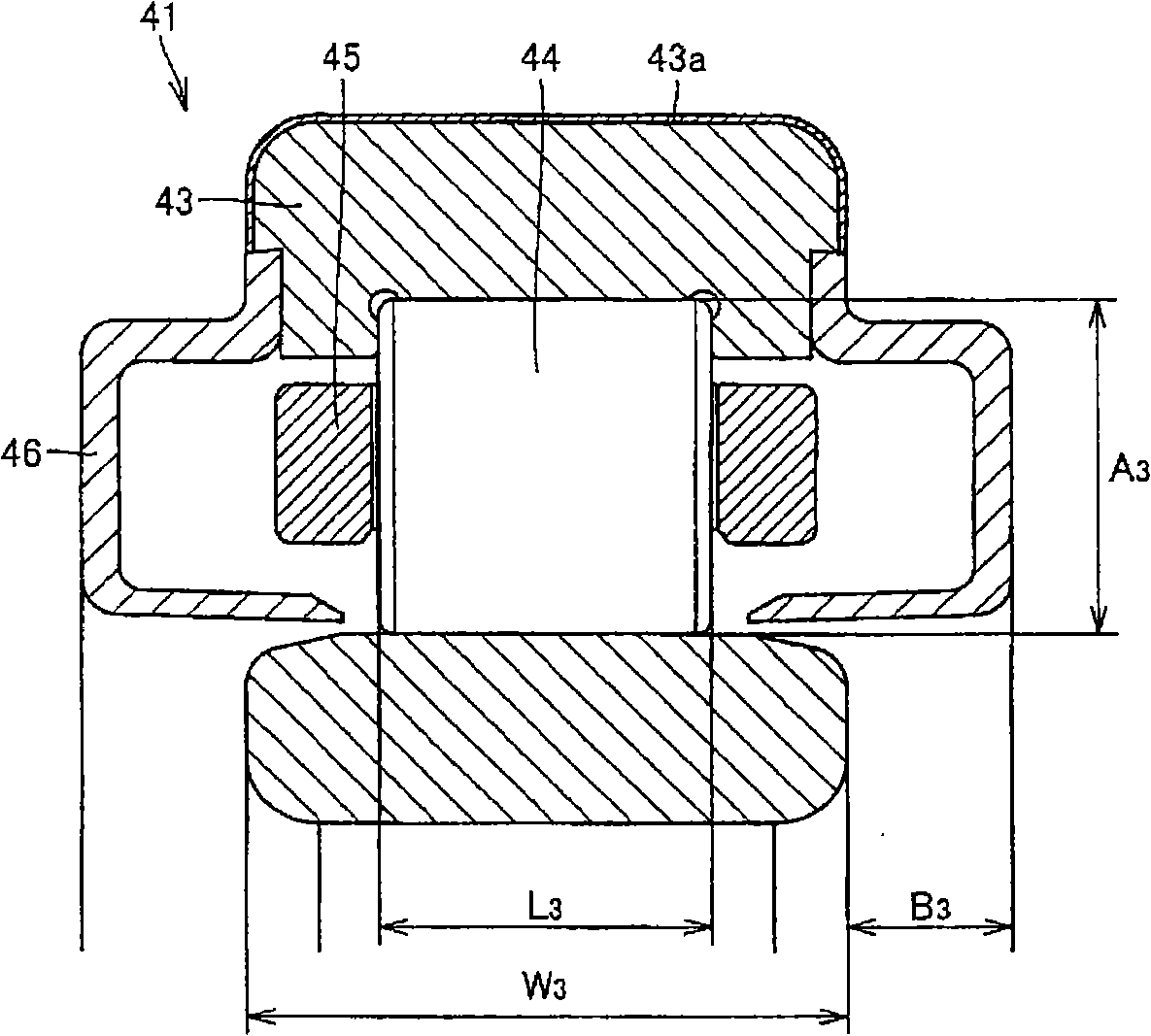

[0104] refer to figure 1 , the cylindrical roller bearing 41 according to one embodiment of the present invention will be described.

[0105] A cylindrical roller bearing 41 includes an inner ring 42, an outer ring 43 having the same axial width as the inner ring 42 and having an insulating layer 43a formed on the outer diameter surface and both end surfaces, and is disposed between the inner ring 42 and the outer ring 43 as rolling elements The cylindrical rollers 44, the cages 45 for keeping the distance between the cylindrical rollers 44, and the seal rings 46 as sealing members protruding from both end surfaces of the inner ring 42 and the outer ring 43 with a substantially U-shaped cross-section. In addition, the insulating layer 43a is formed by sputtering an insulating material such as ceramics, and the bearing internal space is filled with grease.

[0106] In addition, the "approximately U-shaped" mentioned in this specification does not only refer to figure 1 The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com