Plastic crusher

A pulverizer and plastic technology, applied in the field of plastic crushing, can solve the problems of incomplete crushing, inability to clean dirt such as sediment, and unsatisfactory crushing results, and achieve the effect of improving product quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

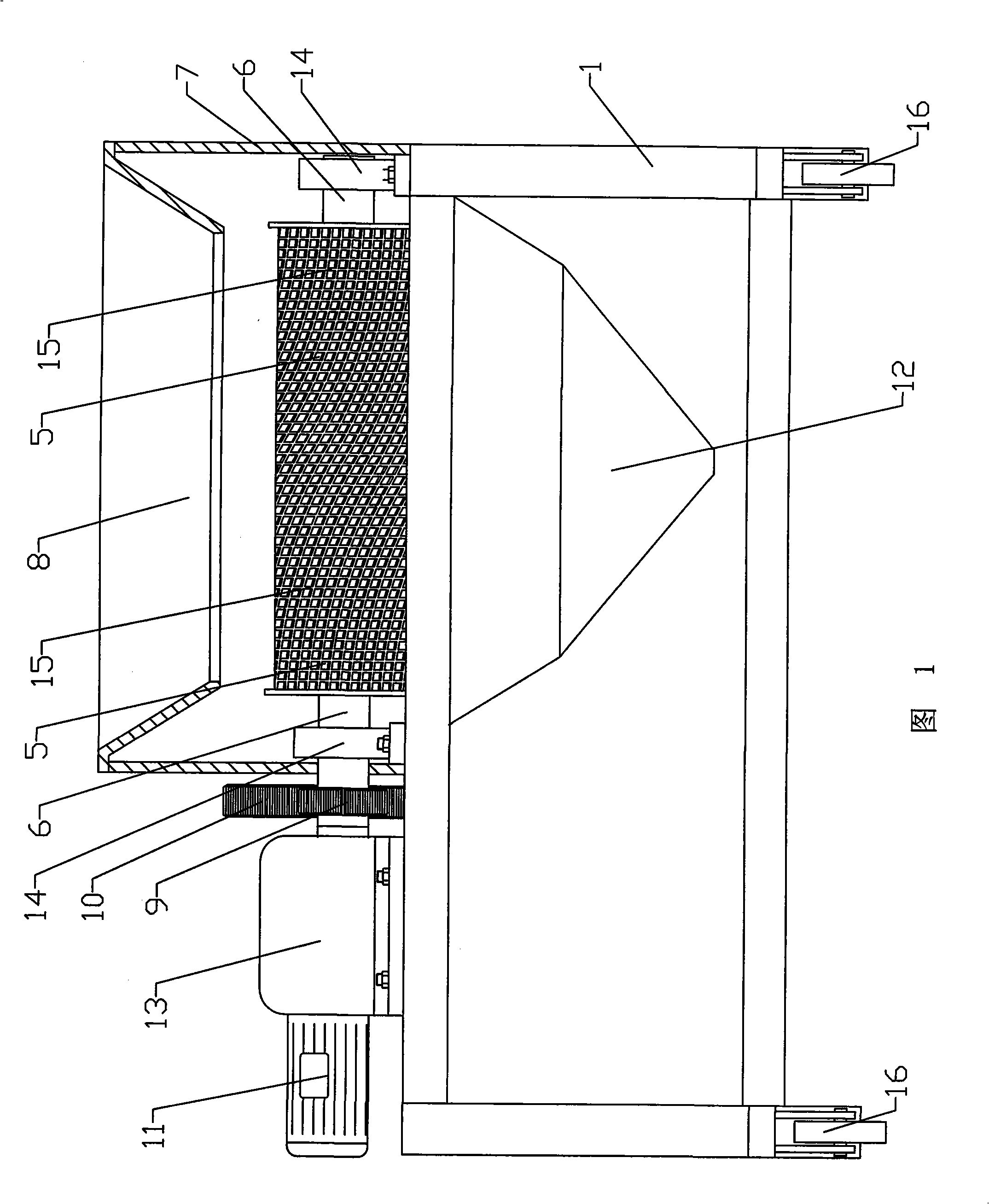

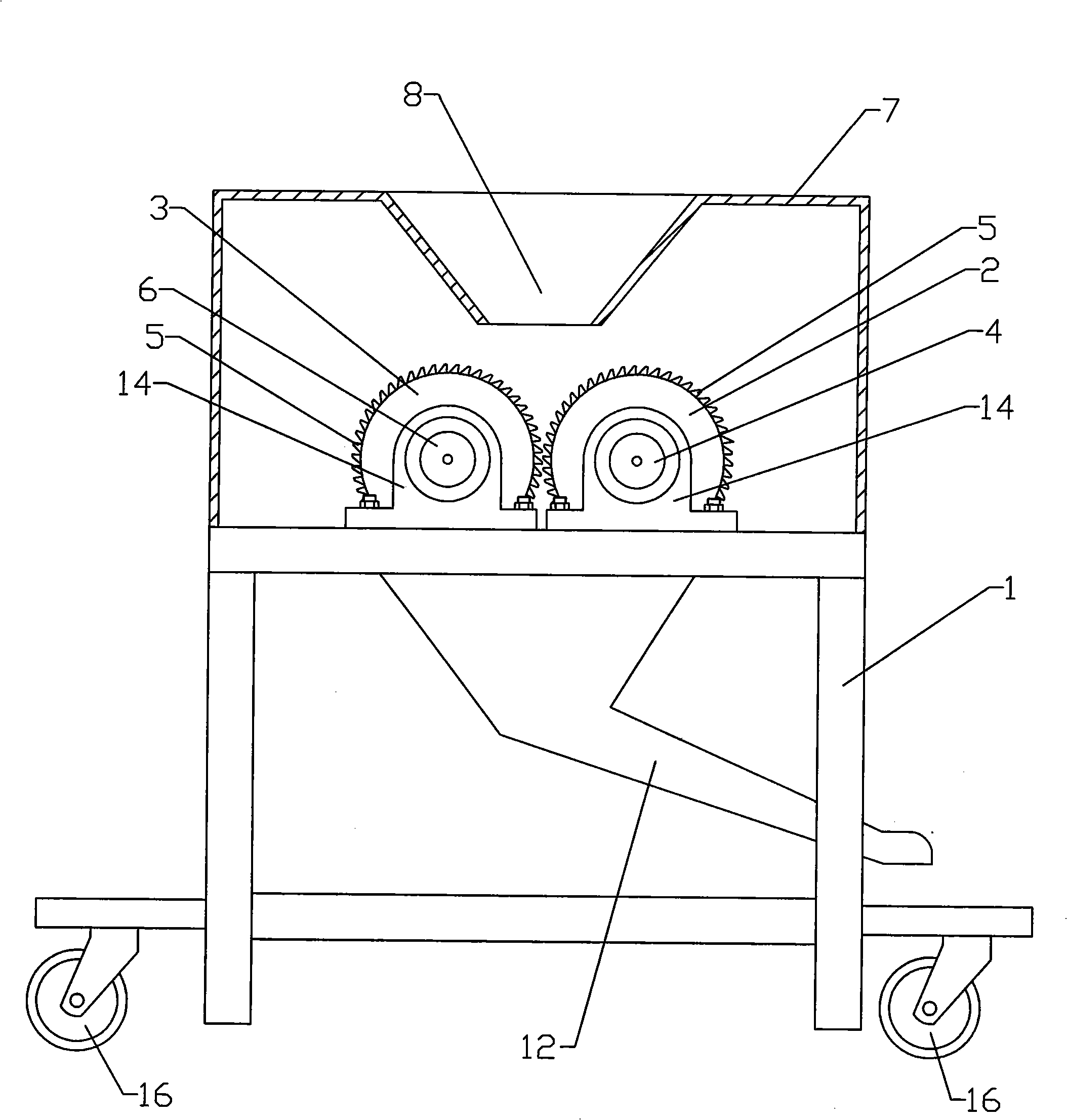

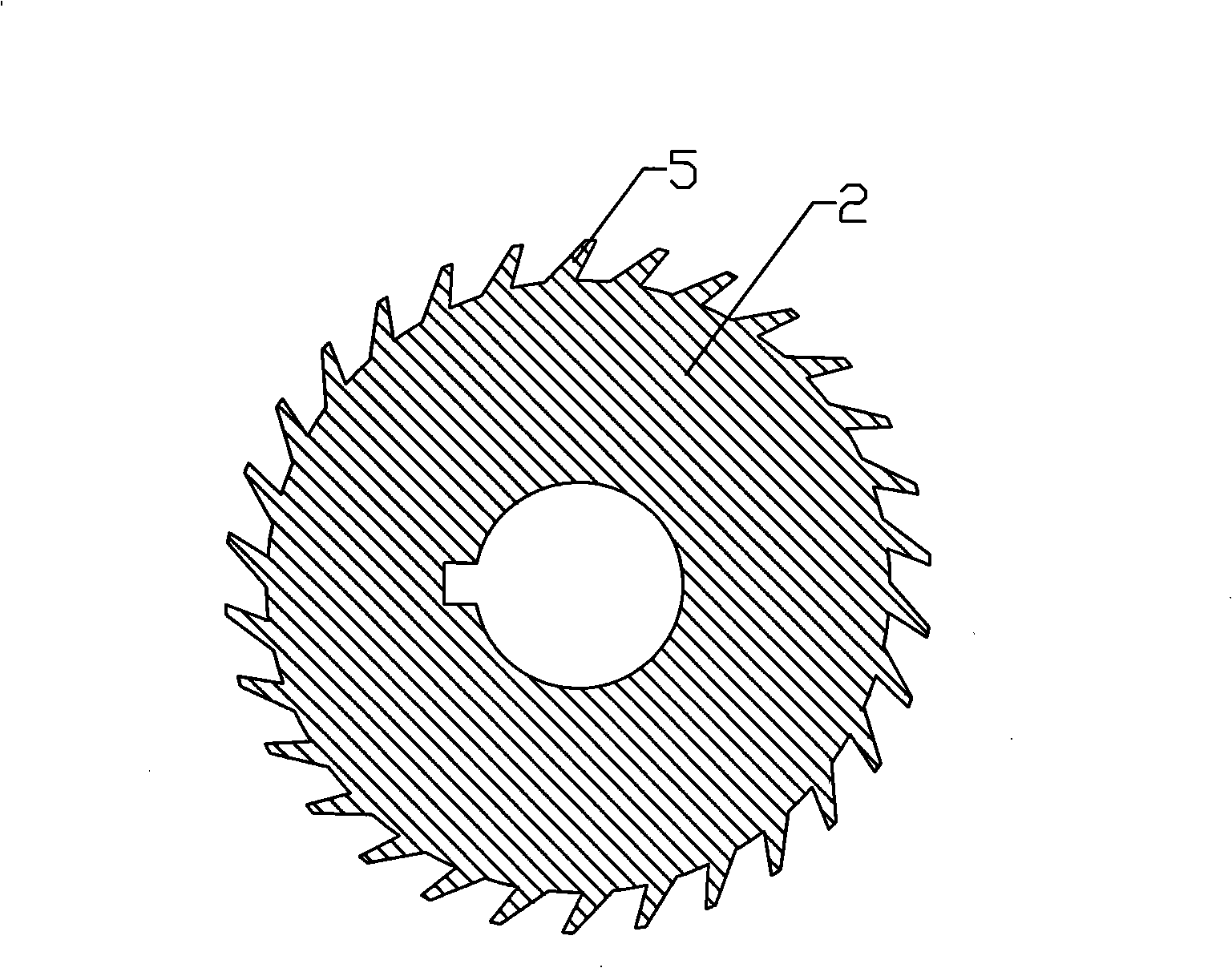

[0019] Embodiment, as shown in Figure 1, figure 2 As shown, the plastic pulverizer includes a frame 1, and a crushing roller 2 and a crushing roller 3 are installed side by side on the frame 1, and the crushing roller 2 and the crushing roller 3 are respectively supported on the frame 1 by bearing blocks 14, The crushing roller 2 and the crushing roller 3 are respectively provided with several rows of crushing teeth 5, and the several crushing teeth 5 are respectively spirally arranged on the outer circumferences of the crushing roller 2 and the crushing roller 3, and the adjacent rows of crushing teeth There are interval grooves 15 therebetween, and the crushing teeth 5 on the crushing roller 2 and the crushing roller 3 are interlacedly arranged, and the crushing teeth 5 on the two crushing rollers extend into each other's interval grooves 15, and the crushing rollers 3 is equipped with a transmission shaft 4, a driven gear 10 is installed on the transmission shaft 4, a rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com