Aluminum electrolysis production cell controlling machine data replenishing system

A technology of supplementary system and cell control machine, which is applied in the field of data supplementation system of aluminum electrolysis production cell control machine, can solve the problems of difficulty in production management, blind spots in control and management, inability to accurately understand the actual situation of the electrolytic cell, etc., so as to avoid production management problems. the effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

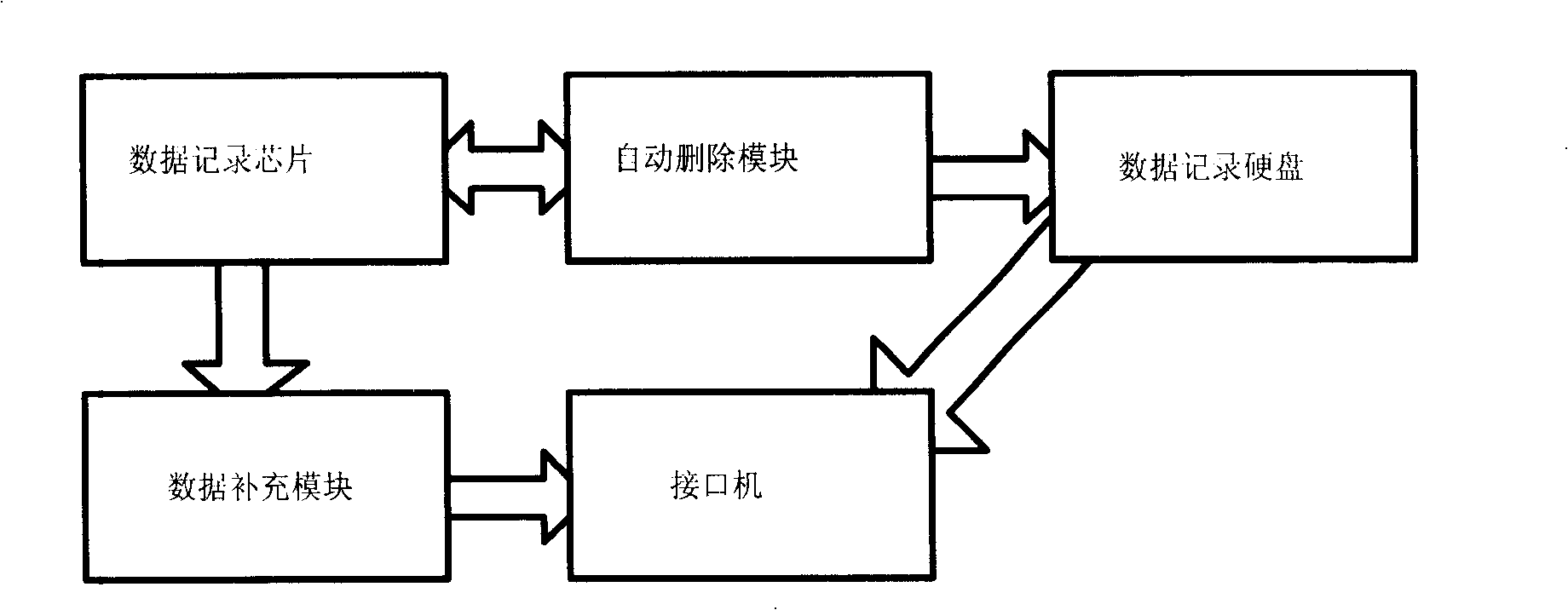

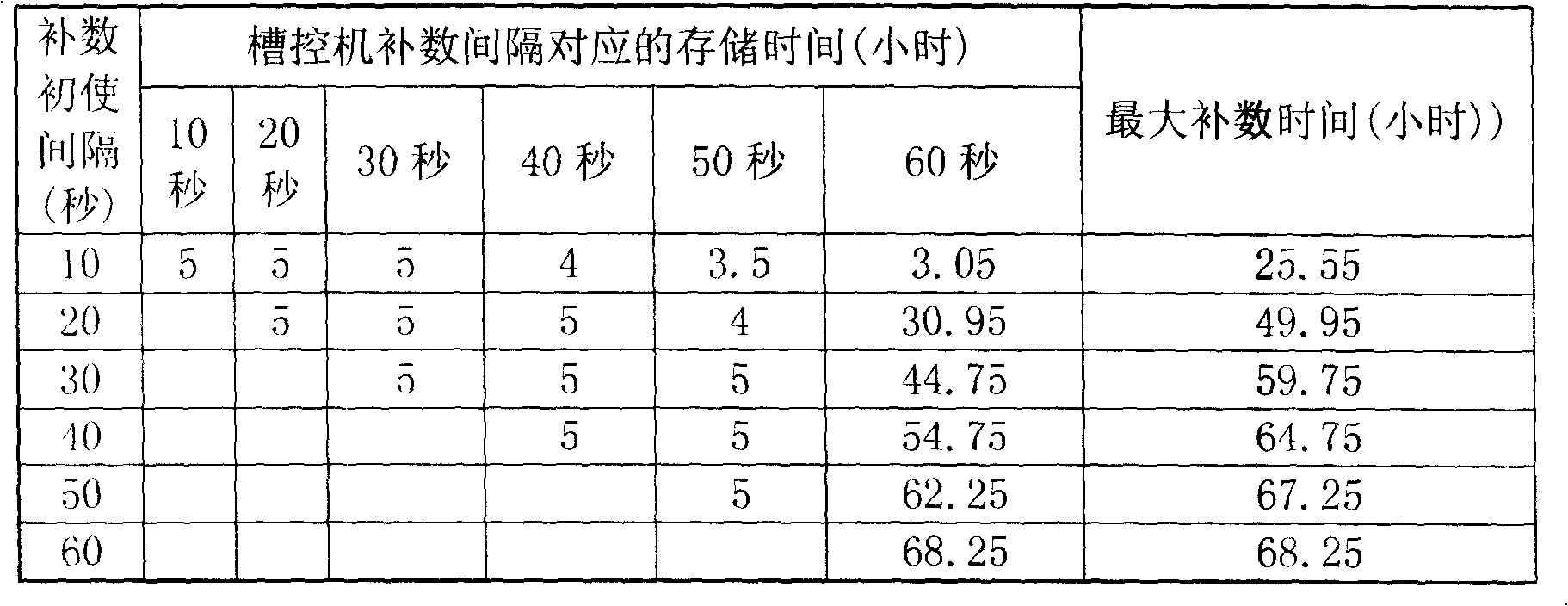

[0013] Embodiment: the slot control machine is provided with a data recording chip, and after the communication with the interface machine is interrupted, the data recording chip records the data and status collected and analyzed by the slot control machine; the data supplement module, the slot control machine communicates with the interface machine After the interruption, use the pre-programmed program to record the data and status collected and analyzed by the slot control machine according to the initial interval of 10s to 60s. The data supplement is sent to the server during the complement time; the automatic deletion module is connected to the data recording chip. After the data supplement is completed, the automatic deletion module transmits the signal to the data recording chip, and the data recording chip deletes the recorded data after receiving the signal. When the communication between the slot control machine and the interface machine is normal, but the server canno...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com