Polymer compositions comprising nucleating or clarifying agents

A kind of composition, nucleating agent technology, applied in the field of polymer composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

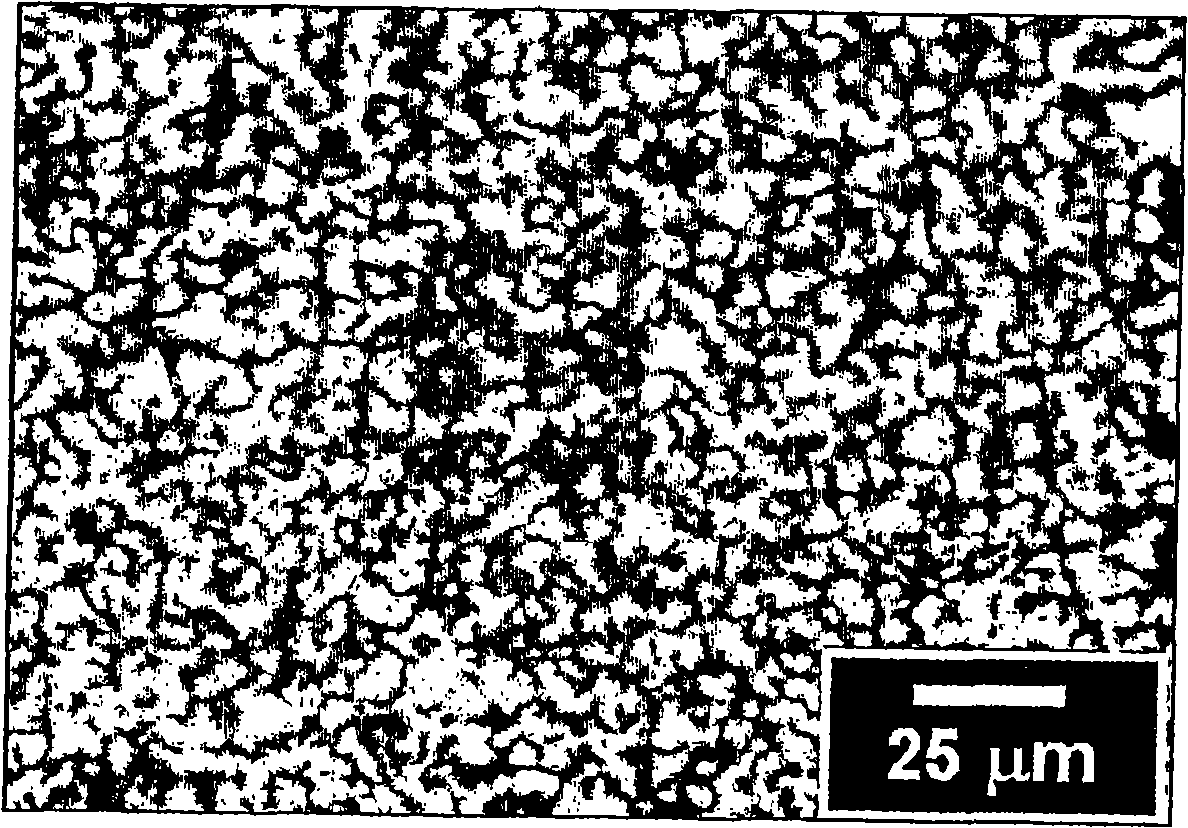

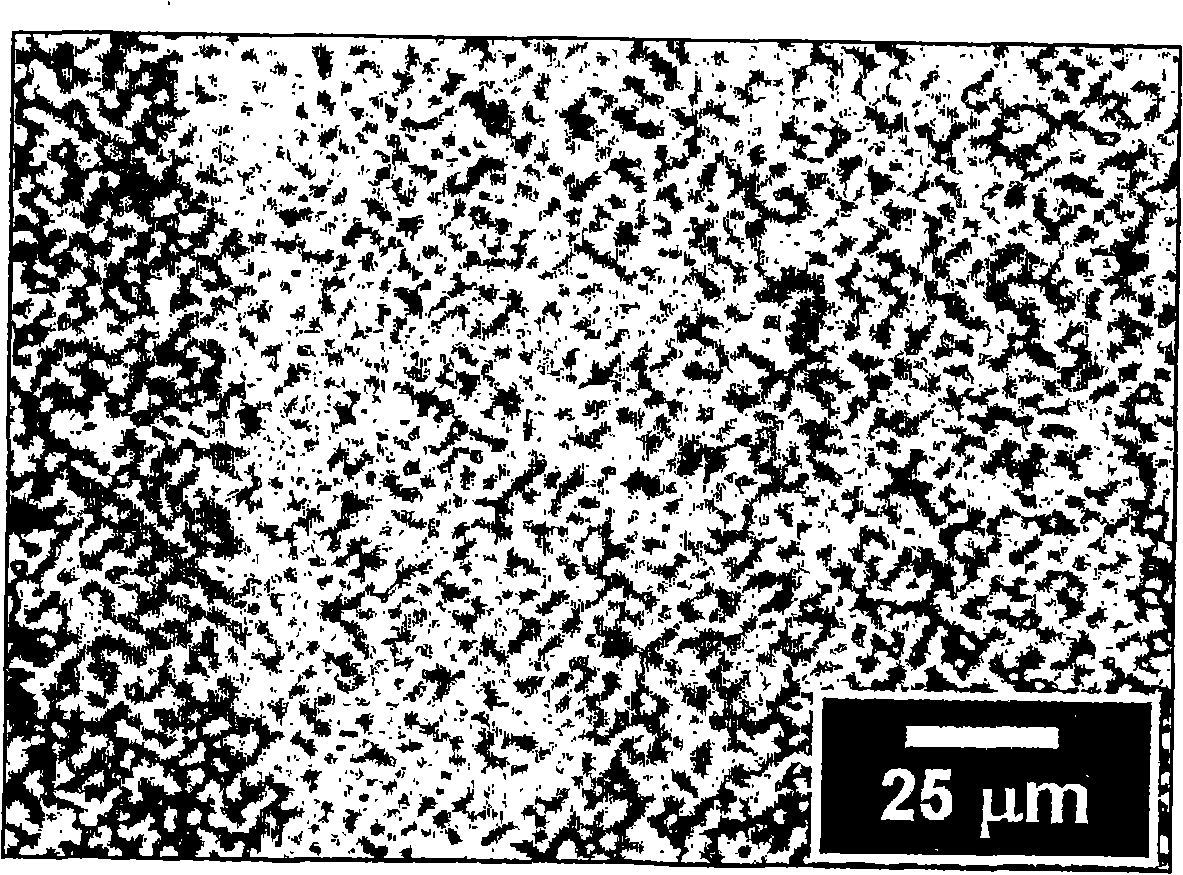

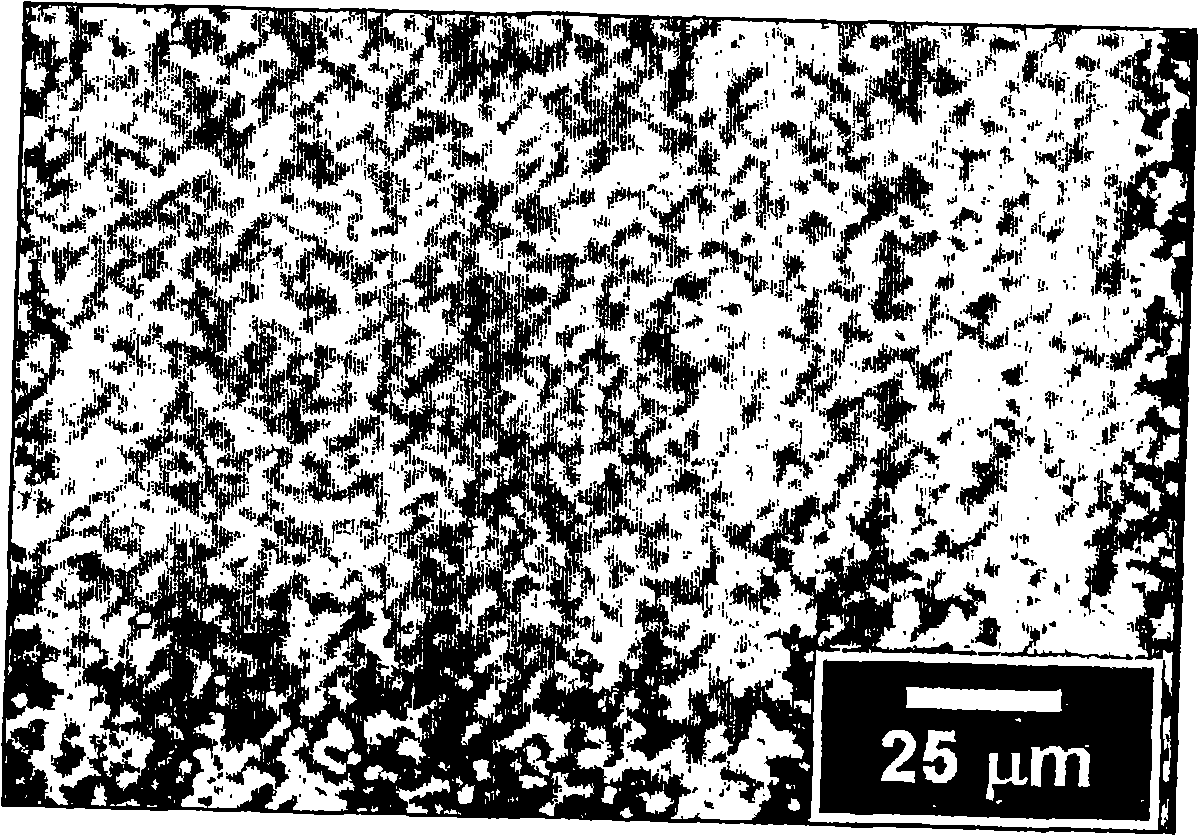

[0064] This example demonstrates the changes in thermal and optical properties exhibited by the polymer compositions described herein. Four samples (1A-1D) were prepared using four commercially available polyethylene resins compounded with about 2.0 wt% (based on the total weight of the polymer composition) of a masterbatch containing about 10 wt% (based on the masterbatch The commercially available 1,3:2,4-bis(3,4-dimethylbenzylidene) sorbitol nucleating agent (the total weight of the feed) ( 3988, available from Milliken Chemical) and approximately 90% by weight (based on the total weight of the masterbatch) of random copolymer polypropylene. Therefore, each compounded polymer composition included 0.2 wt% 1,3:2,4-bis(3,4-dimethylbenzylidene)sorbitol nucleating agent and 1.8 wt% random copolymer propylene.

[0065] Compounded samples were injection molded into 50 mil plaques using an Arburg 40-ton injection molding machine. After storing the molded sheets for at least 12 ...

Embodiment 2

[0073] manufacture of cups

[0074] A series of cups with an average weight of approximately 20 g and a nominal wall thickness of 25 mils (0.025 inches) were produced using a Husky S-90 injection molding machine. The polymer composition used to produce the samples contained approximately 2% by weight (based on the total weight of the composition) of the masterbatch described in Example 1 and 2% by weight of the masterbatch described in Example 9.

Embodiment 3

[0076] A third set of cups (Samples 3A-3B) was produced by the same method as in Example 2. The polymer composition used to produce the cups included a control (sample 3A), which included a commercially available HDPE resin, and a polymer resin according to the invention (sample 3B), which included the same HDPE resin and 2.5 wt % (based on the total weight of the polymer composition) of a masterbatch comprising 4 wt% (based on the total weight of the masterbatch) of commercially available bicyclo[2.2.1]heptane-2,3-dicarboxylate Disodium acid nucleating agent ( HPN-68L, available from Milliken Chemical) and 96 wt% homopolypropylene.

[0077] After storage for at least 12 hours, the samples were evaluated using the BYK Gardner Haze-Gard Plus to determine haze and clarity.

[0078] Table 4. Optical Properties of Samples 3A-3B.

[0079] sample

[0080] As can be seen from the data shown in Table 4, the cups produced using the polymer composition of the present inven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com