Convection guide device

A technology of conveying platform and adjusting part, applied in the field of conveying, can solve the problems of waste, failure to use resources effectively, increase production cost, etc., and achieve the effect of reducing production cost, reducing manpower and time, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

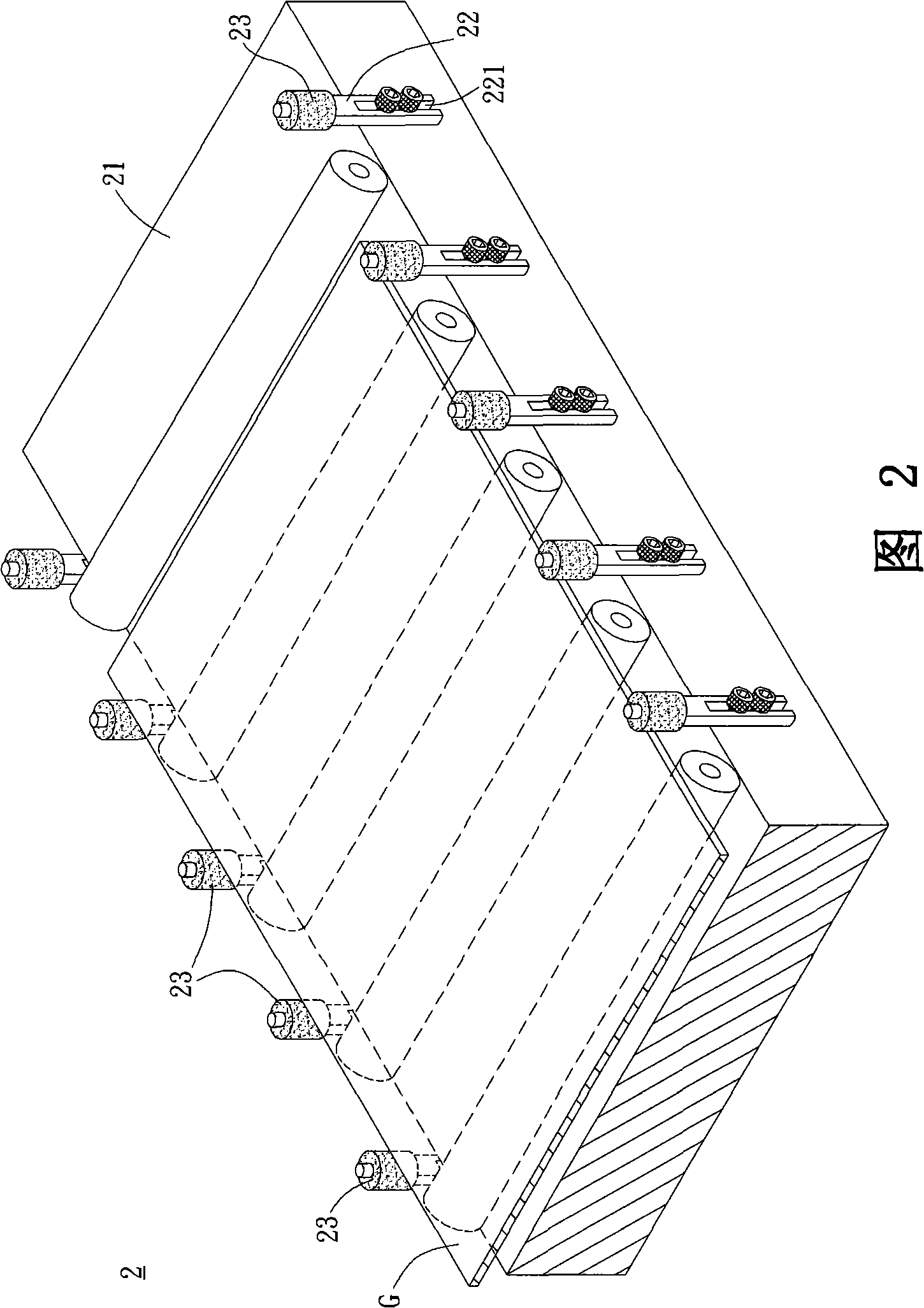

[0034] The first embodiment, please refer to FIG. 2 , the conveying and guiding mechanism 2 of the first embodiment of the present invention is used to convey an object such as a glass substrate G. As shown in FIG. The transmission guiding mechanism 2 includes a transmission platform 21 , several guiding components 23 and several adjusting and fixing components 22 .

[0035] The adjusting and fixing components 22 are respectively disposed on opposite sides of the conveying platform 21 . Each adjustment and fixing assembly 22 has an adjustment part 221, and the adjustment part 221 is connected with the transmission platform 21. The connection method can be locked, clamped, fitted or a combination thereof. The adjustment part 221 includes a groove or an opening , in this embodiment, the adjustment part 221 is illustrated by taking a groove connected with the delivery platform 21 by locking as an example, but it is not intended to limit the present invention.

[0036] The guidin...

no. 2 example

[0046] The second embodiment, please refer to Fig. 5, the difference between the transmission guide mechanism 4 of the second embodiment of the present invention and the first embodiment is that the adjustment and fixing assembly 42 can not only adjust the height of the guide assembly 43, but also Adjust the distance between the guide components 43 arranged opposite to each other.

[0047]In this embodiment, the adjusting and fixing component 42 is substantially L-shaped, and the adjusting and fixing component 42 has a first adjusting part 421 and a second adjusting part 422, and the first adjusting part 421 is connected with the guide component 43 and the second adjusting part 421. The adjustment part 422 is connected. Wherein, the first adjustment part 421 includes a groove or an opening, and the first adjustment part 421 and the second adjustment part 422 can be connected by locking, clamping, fitting or a combination thereof, and the second adjustment part 422 It can also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com