Elevator door sill with hidden guide

A threshold and guide rail technology, applied in the direction of elevators, transportation and packaging in buildings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

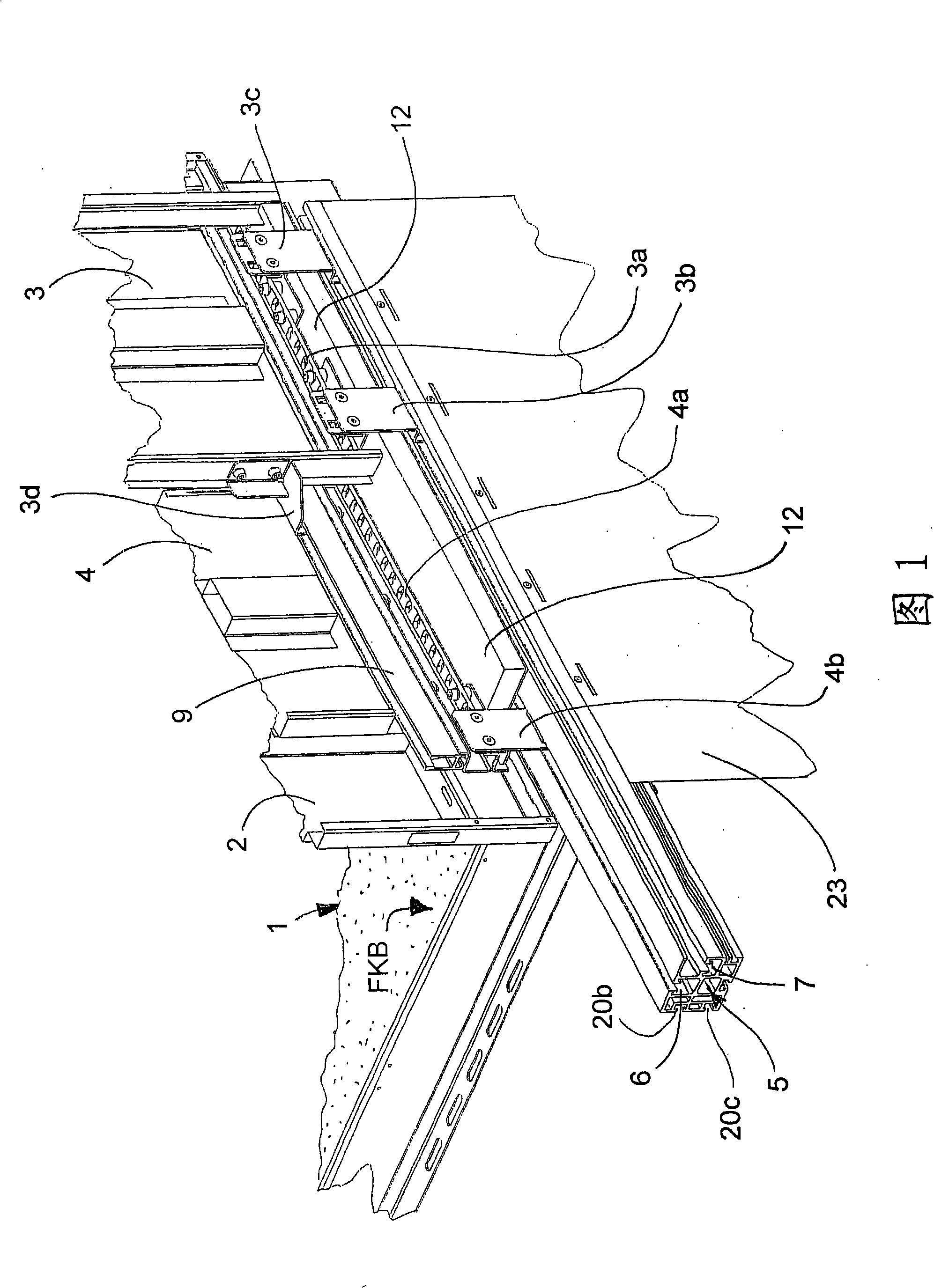

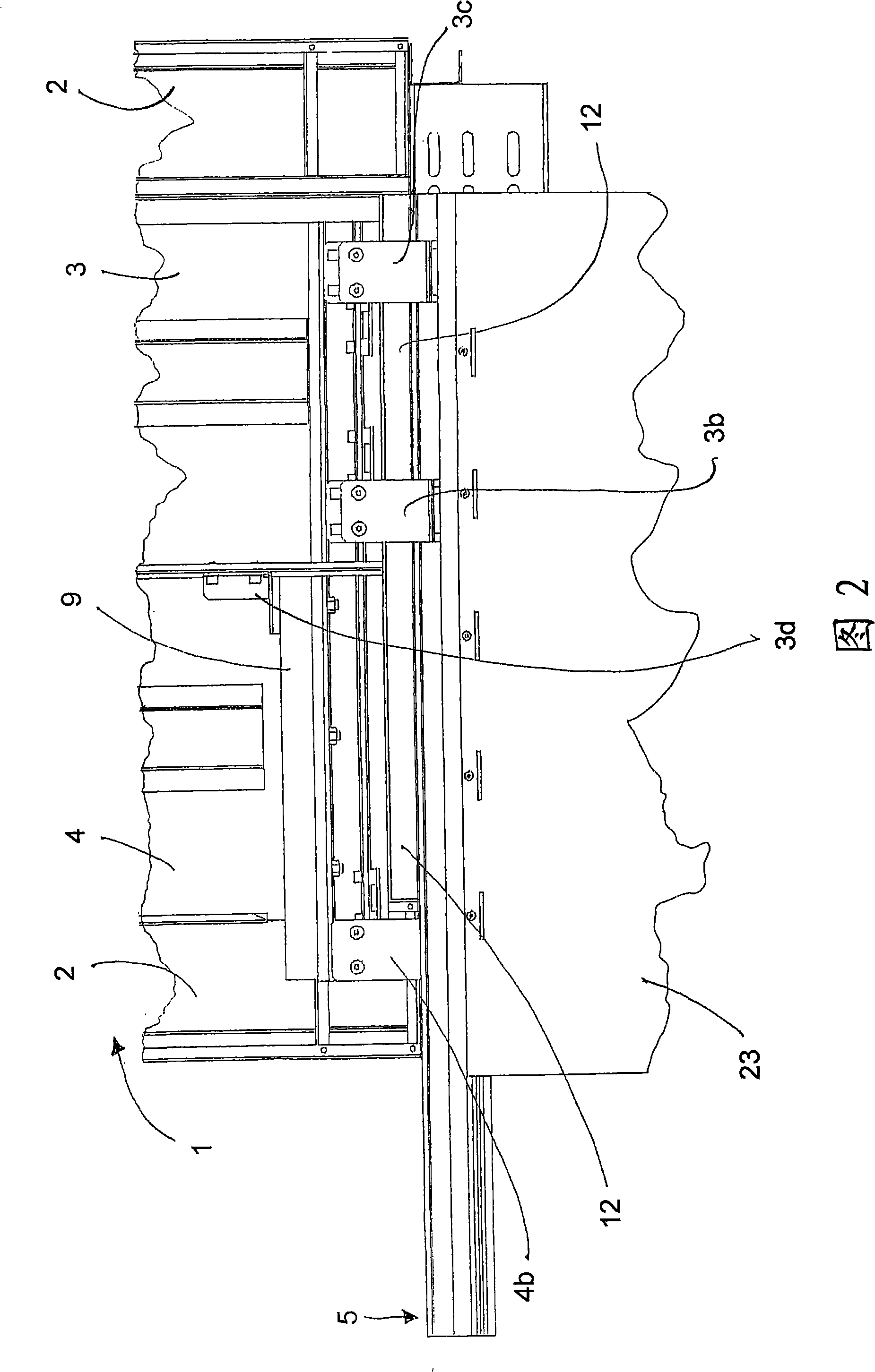

[0029] Figure 1 shows a view (from the outside) of the door area of an elevator car 1 in a schematic representation;

[0030] The invention will be described in terms of an elevator car door system. However, the description is similarly applicable to elevator hoistway door systems as well.

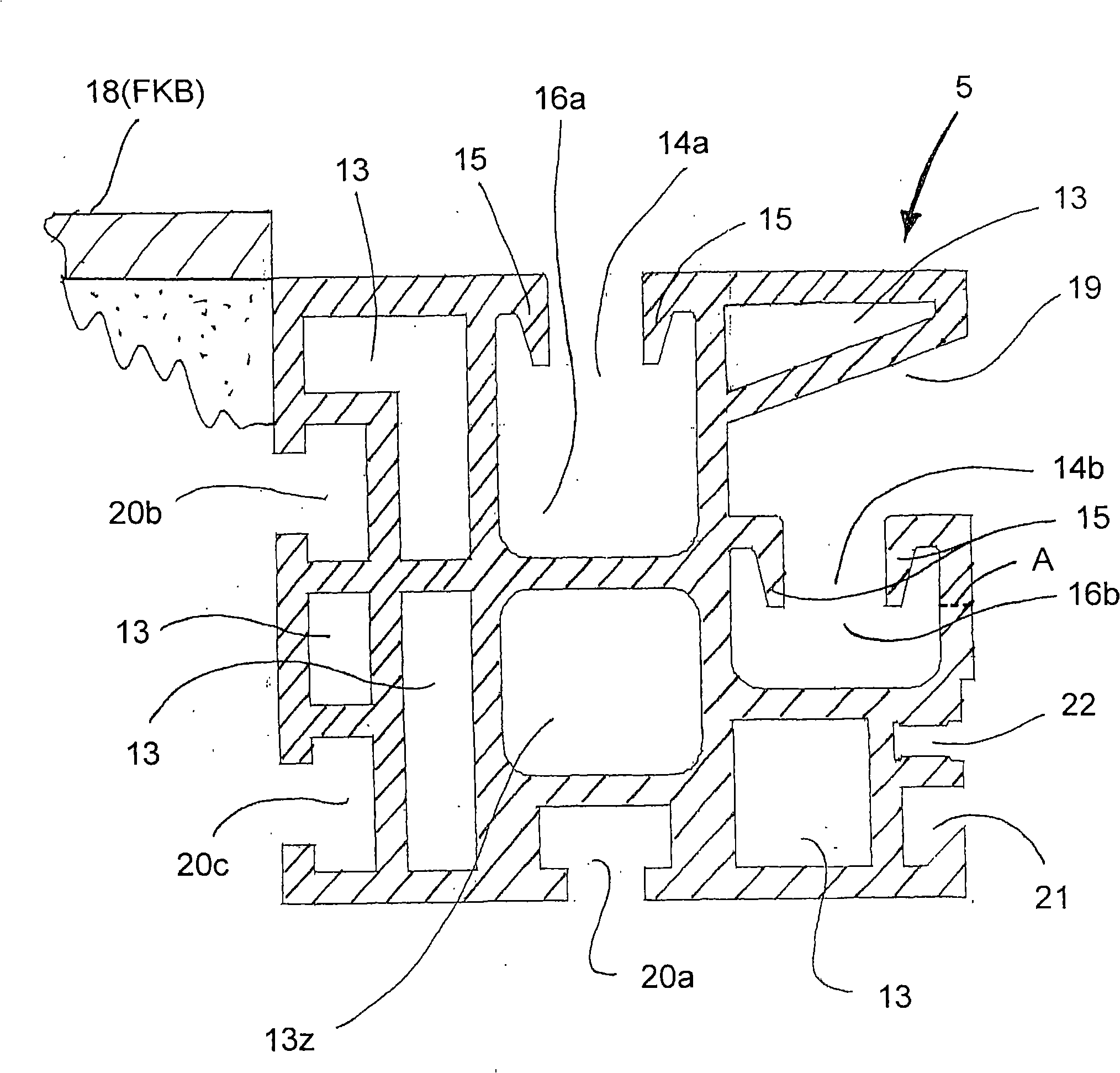

[0031] Here, the elevator car door system comprises two frame surfaces 2 forming a kind of door frame (elevator car door front) for entering the elevator from the front, two door panels 3 and 4 and a threshold 5 car. The threshold 5 is fixed to the lower front edge of the elevator car by T-grooves 20b and 20c arranged on the left side thereof in FIG. 1 . Two door panels 3 and 4 are opened to the left. The two door panels are telescopic in the process, which means that the faster door panel 3 is retracted behind the slower door panel 4 in the open state, looking out from the inside of the elevator car. For this reason, the threshold 5 also protrudes to the left into the elevator shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com