Non-pressure biogas generating pit

A biogas digester and air extractor technology, which is used in gas production bioreactors, biochemical instruments, waste fuels, etc., can solve the problems of small volume, easy corrosion and gas leakage of the pool body, and inconvenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

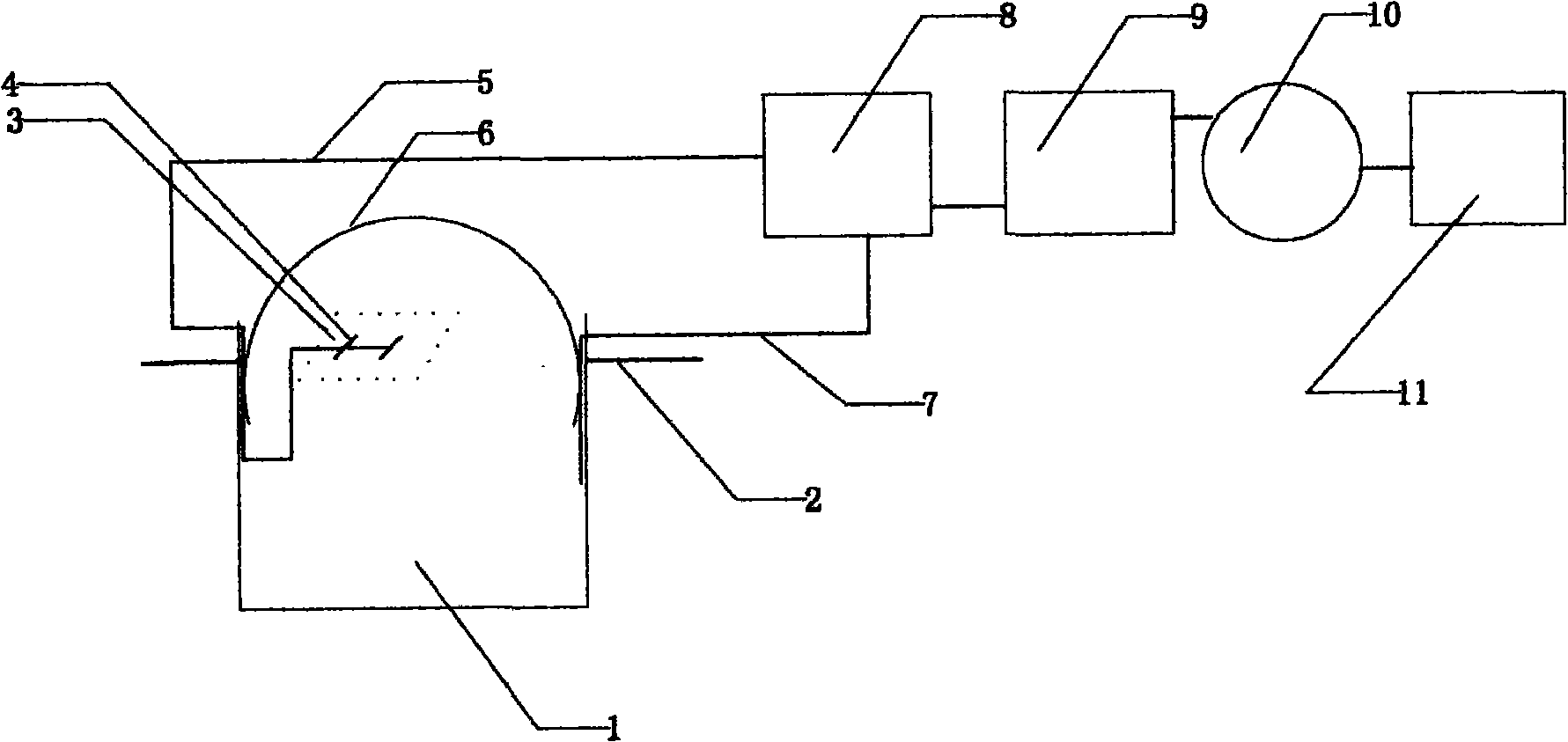

[0006] Further elaboration will be made below in conjunction with accompanying drawings and specific examples:

[0007] See accompanying drawing: Implementation method:

[0008] Dig a cuboid biogas fermentation tank 1, build the dug pool with bricks, after building it, smooth it with cement, the top of the pool will be about 20-30 centimeters higher than the ground level 2, to prevent rainwater from pouring into the pool, The bottom of the pool should be paved with bricks, and then smoothed and calendered with cement. After 7 days of maintenance, water is poured to test the leak. If the water is filled, the drop is less than 10 cm within 2 hours. It is normal, otherwise, the pool is leaking. Add materials after building the pond. If the fermented material is straw, add urea to adjust the carbon-to-nitrogen ratio to about 25:1, then add part of the biogas fermentation liquid into the biogas digester, and place a foam plastic board 3 in the middle of the digester. The plastic p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com