Method and device for measuring thermal conductivity, and gas component ratio measuring device

A measuring device and measuring method technology, applied in the direction of measuring device, analyzing material, thermal conductivity of materials, etc., can solve the problems of time-consuming, expensive, and complex structure of the analyzing device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, a thermal conductivity measurement method, a thermal conductivity measurement device, and a gas component ratio measurement device according to the present invention will be described with reference to the drawings.

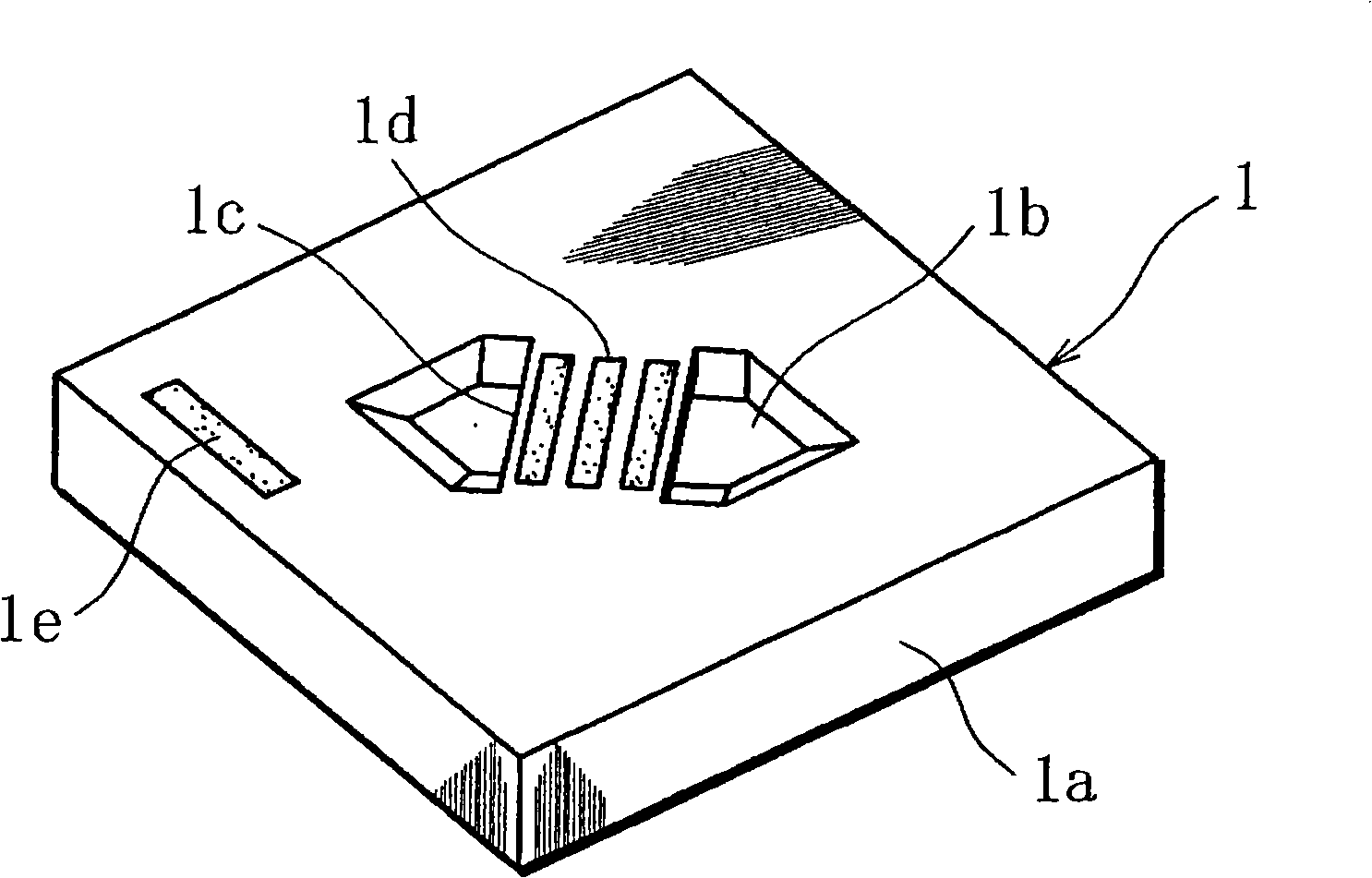

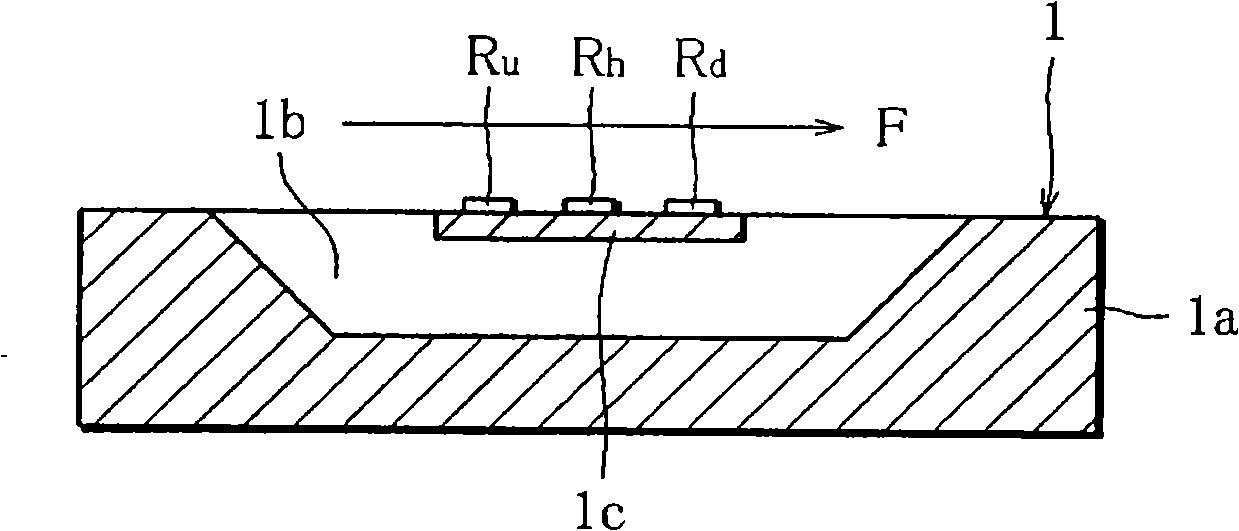

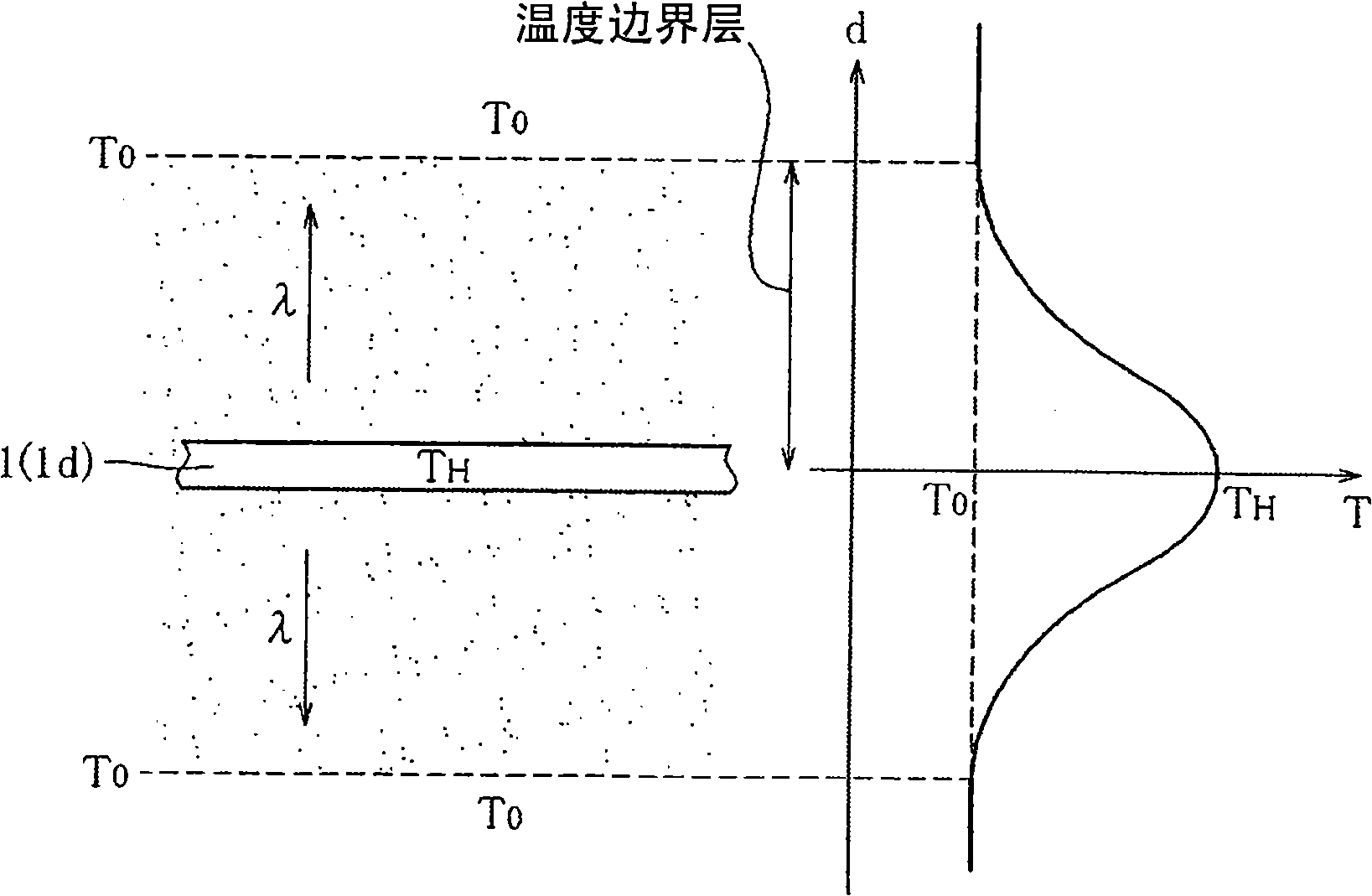

[0031] The present invention is to use for example figure 1 The micro-heater 1 whose schematic configuration is shown basically measures the thermal conductivity of the atmospheric gas (pure gas or mixed gas) based on the calorific value of the above-mentioned micro-heater 1 . Micro-heater 1 is that for example thickness is 0.5mm, length and width dimension are the surface of silicon chip 1a of about 1.5mm respectively, forms concave chamber 1b, bridges on this chamber 1b simultaneously, forms the diaphragm 1c of thin film, A minute heating resistor (heater) 1d made of platinum or the like is provided on the diaphragm 1c. In addition, generally, a temperature sensor 1e for measuring the surrounding temperature is provided on the peripheral p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com