Micro electro mechanical system (MEMS) gyroscope, chip level temperature control method thereof and processing method thereof

A gyroscope and chip technology, which is applied in the direction of speed measurement by gyro effect, instrument, metal material coating process, etc., can solve the problems of unfavorable miniaturization and integration of micro gyroscopes, process incompatibility, and reduce micro gyroscopes, etc., to achieve Easy to integrate and array, omit the refrigeration device, and the process achieves simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

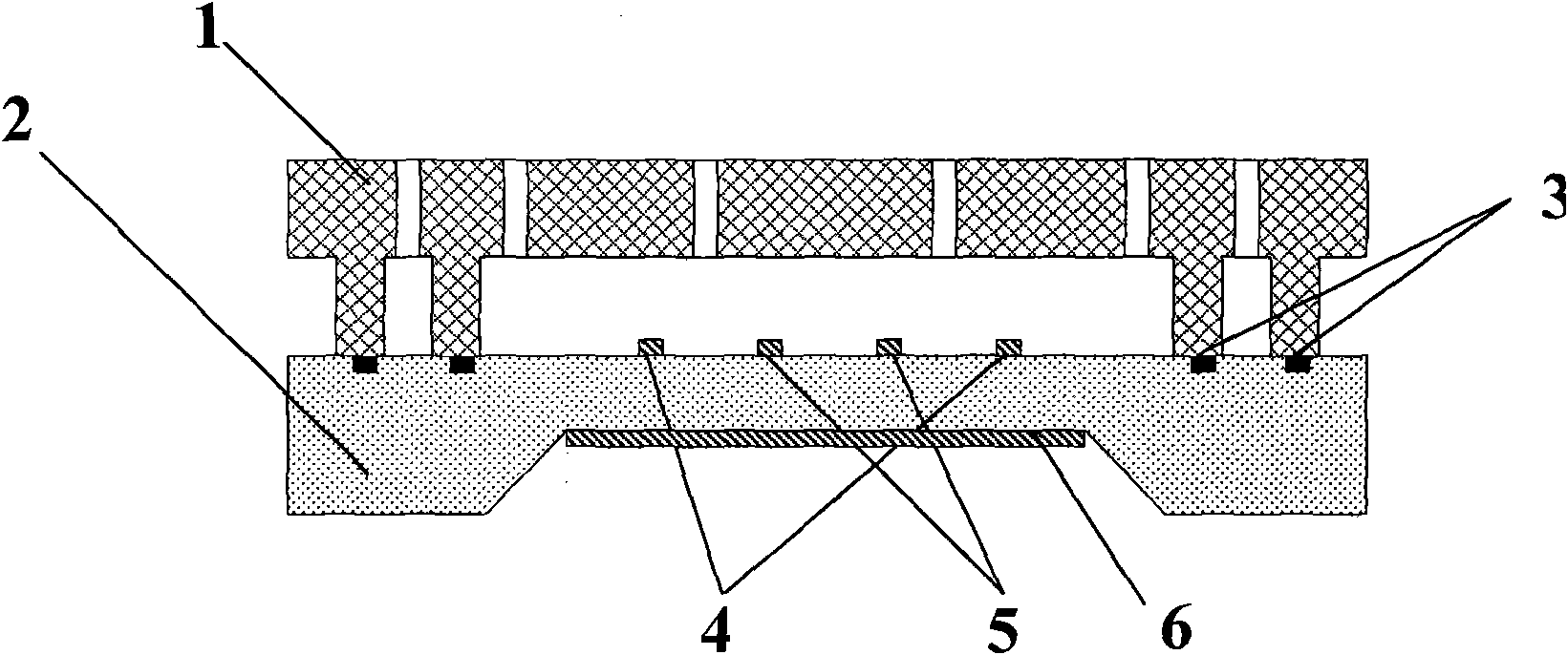

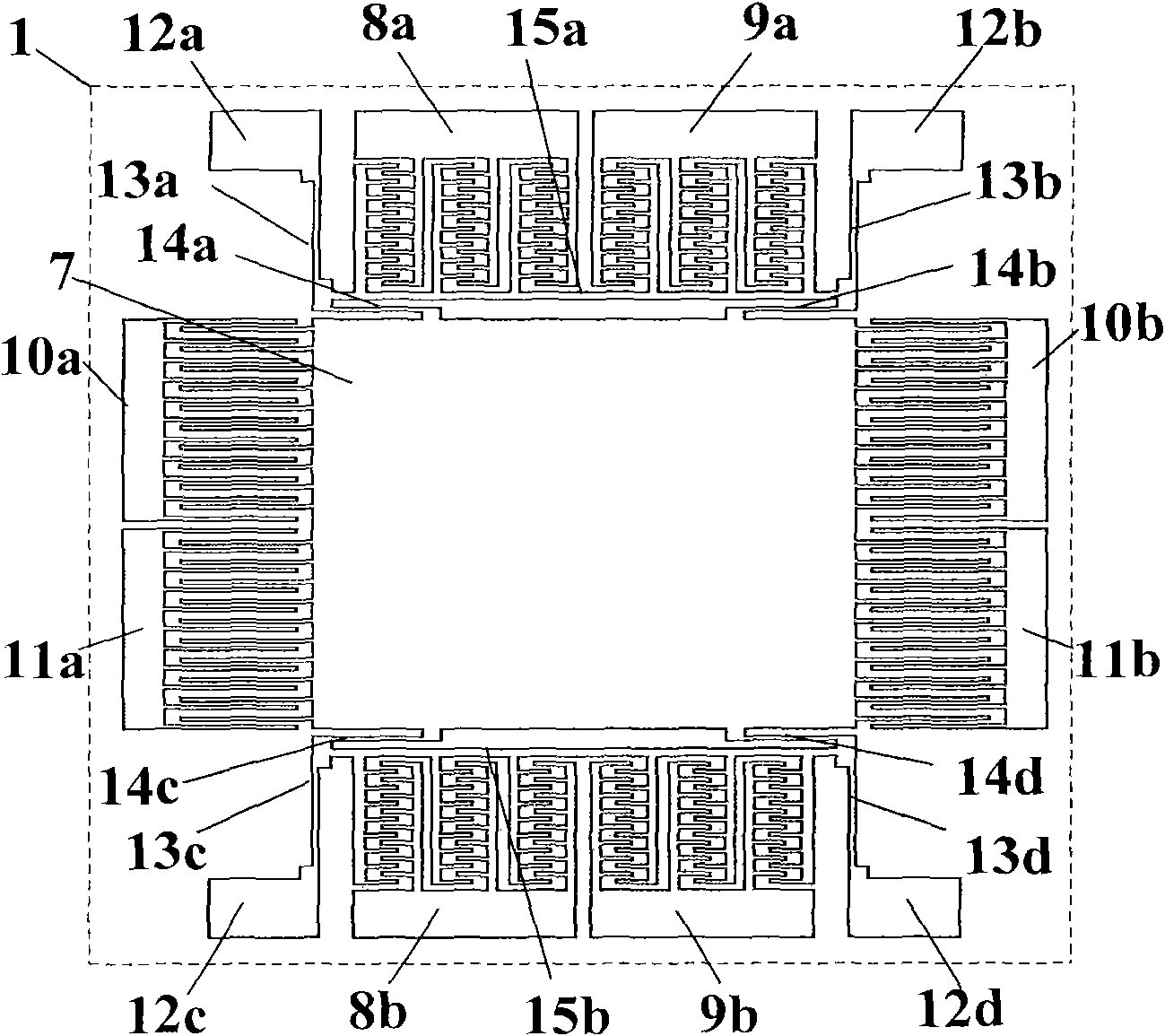

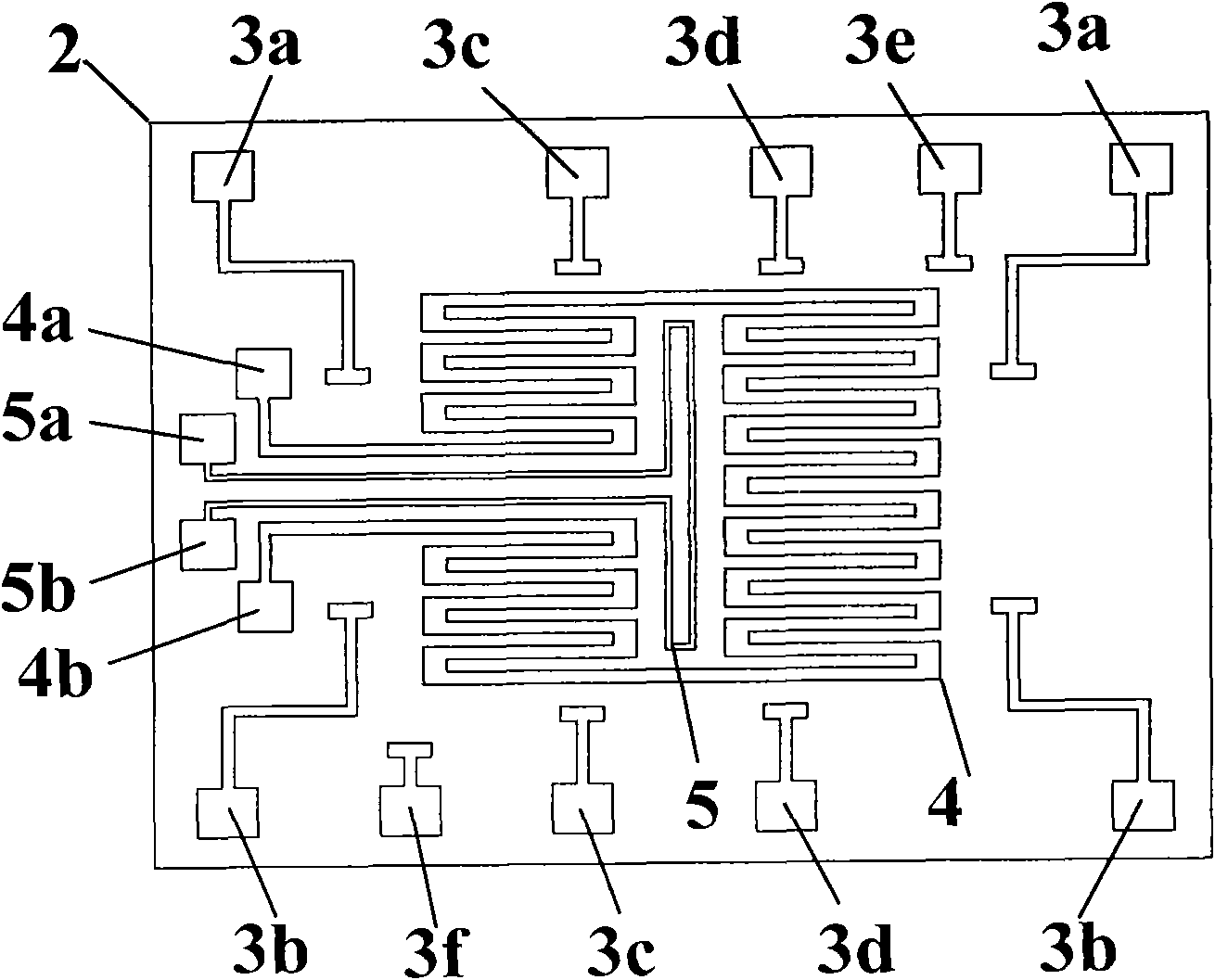

[0038] A MEMS gyroscope integrated with a micro heater and a temperature sensor is composed of an upper part and a lower part. and a glass base for the signal leads. In order to allow the silicon structure part of the MEMS gyroscope chip to be heated evenly and measure the temperature of the silicon structure in real time, the micro heater and temperature sensor adopt two sets of nested serpentine structures and are located directly below the silicon structure; in order to achieve high sensitivity and repeatability Well, the micro heater and temperature sensor use Pt metal material. The MEMS gyroscope chip is heated by applying a voltage across the micro-heater, and the integrated temperature sensor is used to monitor the temperature of the gyroscope chip in real time to drive the peripheral circuit to adjust the voltage across the heater to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com