Grinding mechanism of coffee-making machine

A grinding mechanism and coffee machine technology, applied in coffee mills, spice mills, household appliances, etc., can solve the problems of unsatisfactory coffee powder, unadjustable powder thickness of coffee powder, unreliable power transmission of grinding motor, etc., to achieve easy removal Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

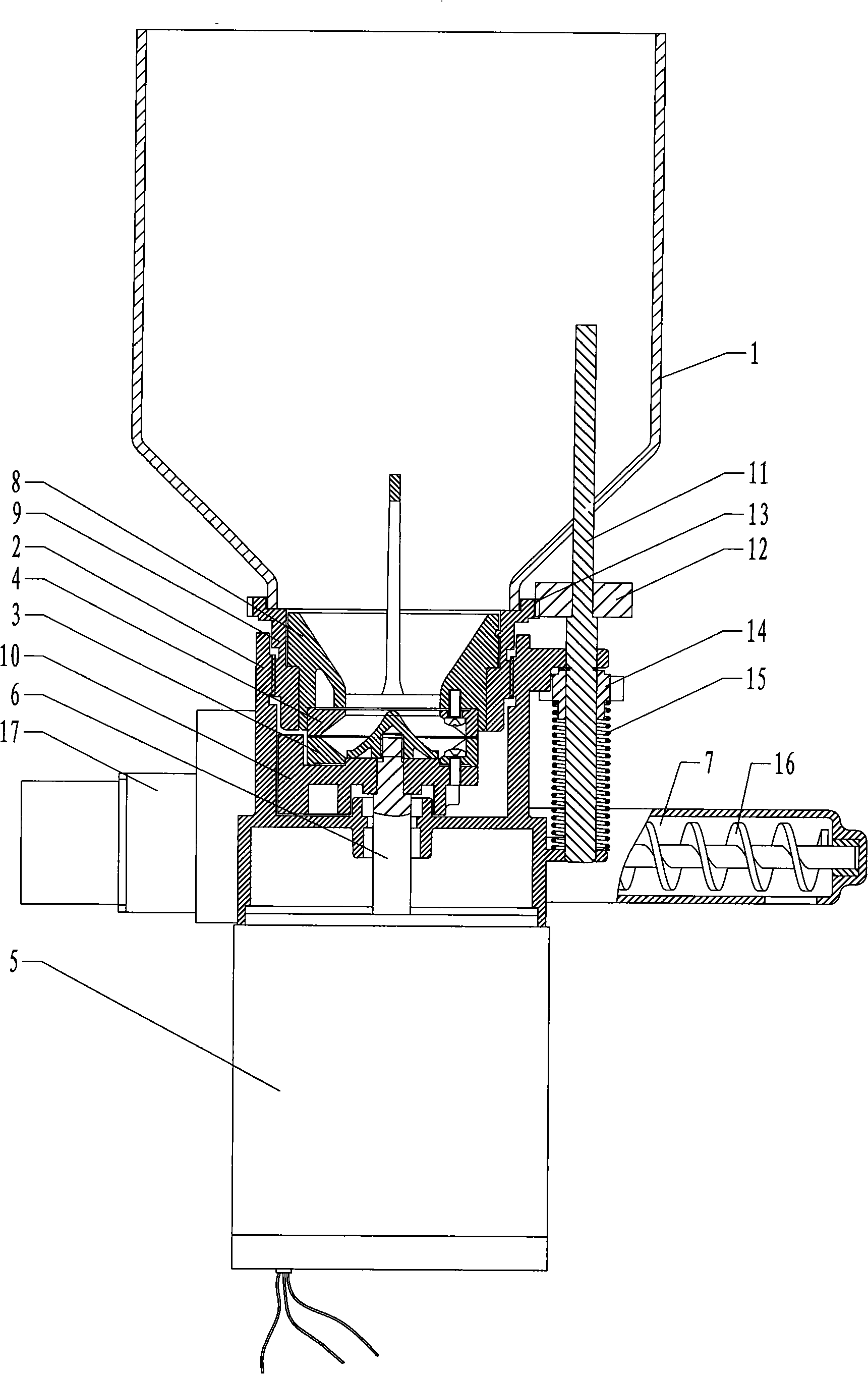

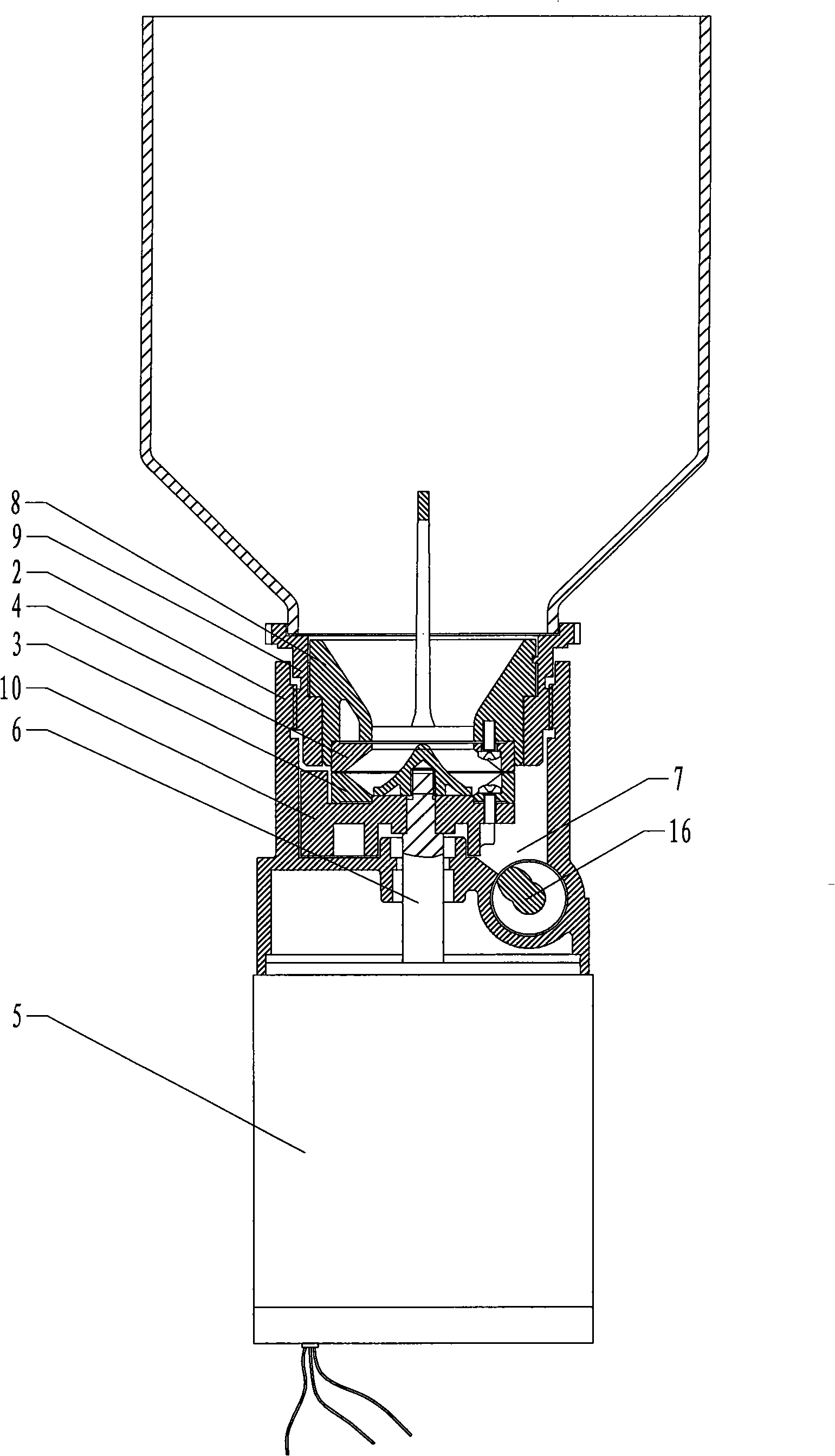

[0013] combine figure 1 , figure 2 Shown: the grinding mechanism of the coffee machine of this embodiment, the bean bin 1 is arranged in the grinding device, the grinding body 2 is arranged under the bean bin, the rotating grinding disc 3 and the stationary grinding disc 4 are arranged in the grinding body, and both grinding discs are provided with Grinding the teeth, the rotating shaft 6 of the grinding motor 5 is connected with the rotating grinding disc 3, and the powder outlet is provided with a powder outlet channel 7. The stationary grinding disc 4 is fixed on the stationary grinding disc frame 8, and the stationary grinding disc frame 8 is fixed on the connecting piece 9 with thread on the outer edge, and the connecting piece 9 is screwed on the grinding body 2; the rotating grinding disc 3 is connected with the rotating shaft 6 through the rotating grinding disc frame 10 .

[0014] The grinding mechanism of the coffee machine is provided with a powder fineness adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com