Steel lining polyethylene integral moulding agitator

A technology of integral molding and polyethylene, applied in mixers with rotating stirring devices, chemical instruments and methods, dissolution, etc., can solve the problems of low viscosity of the medium and insufficient strength of the all-plastic stirrer, so as to improve the impermeability strength, Overcoming the incompatibility of physical properties and the effect of temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

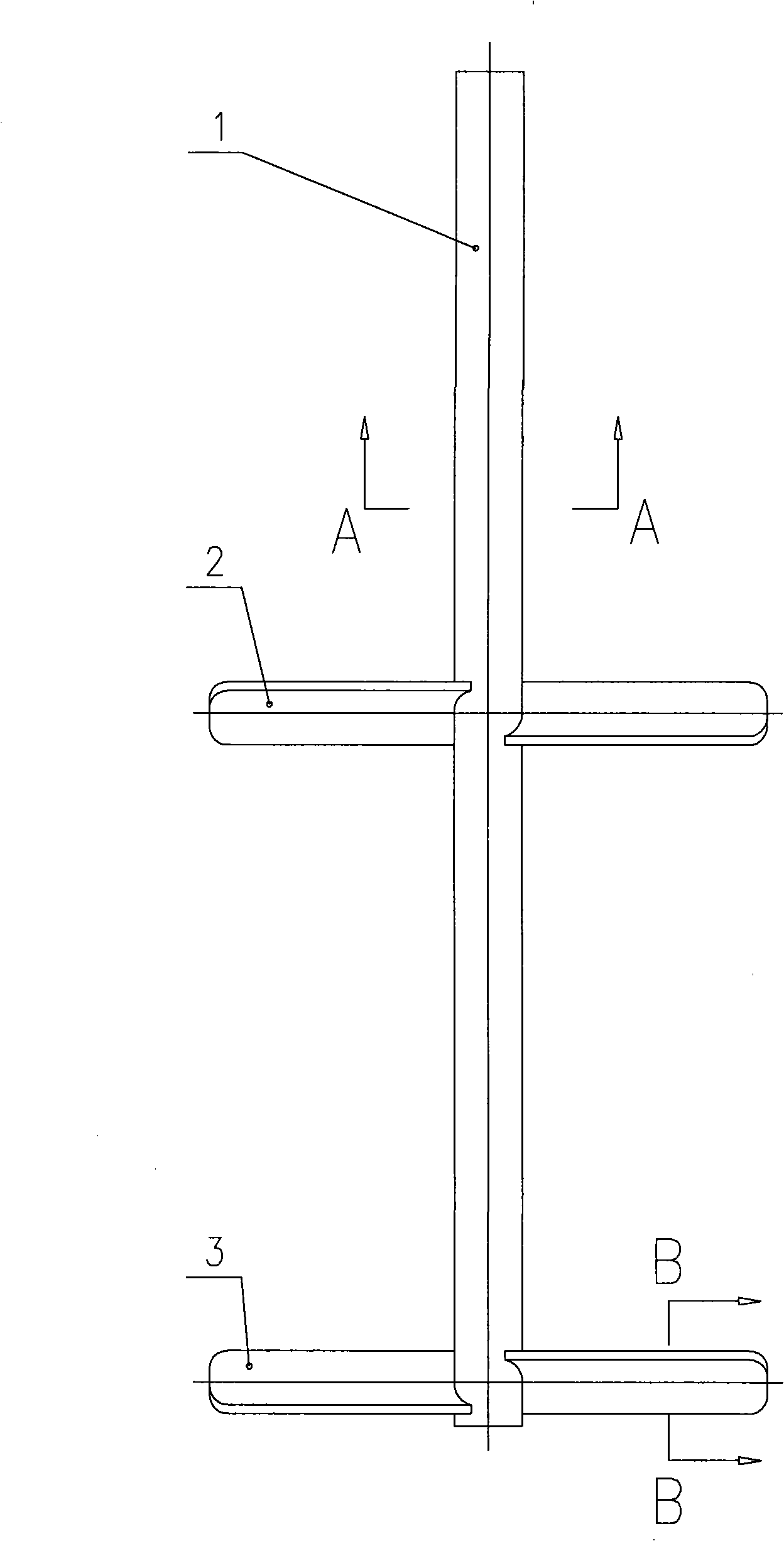

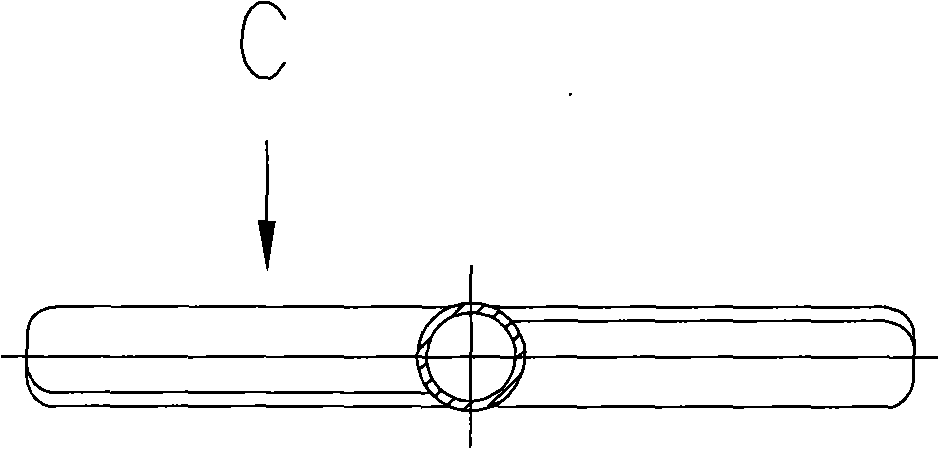

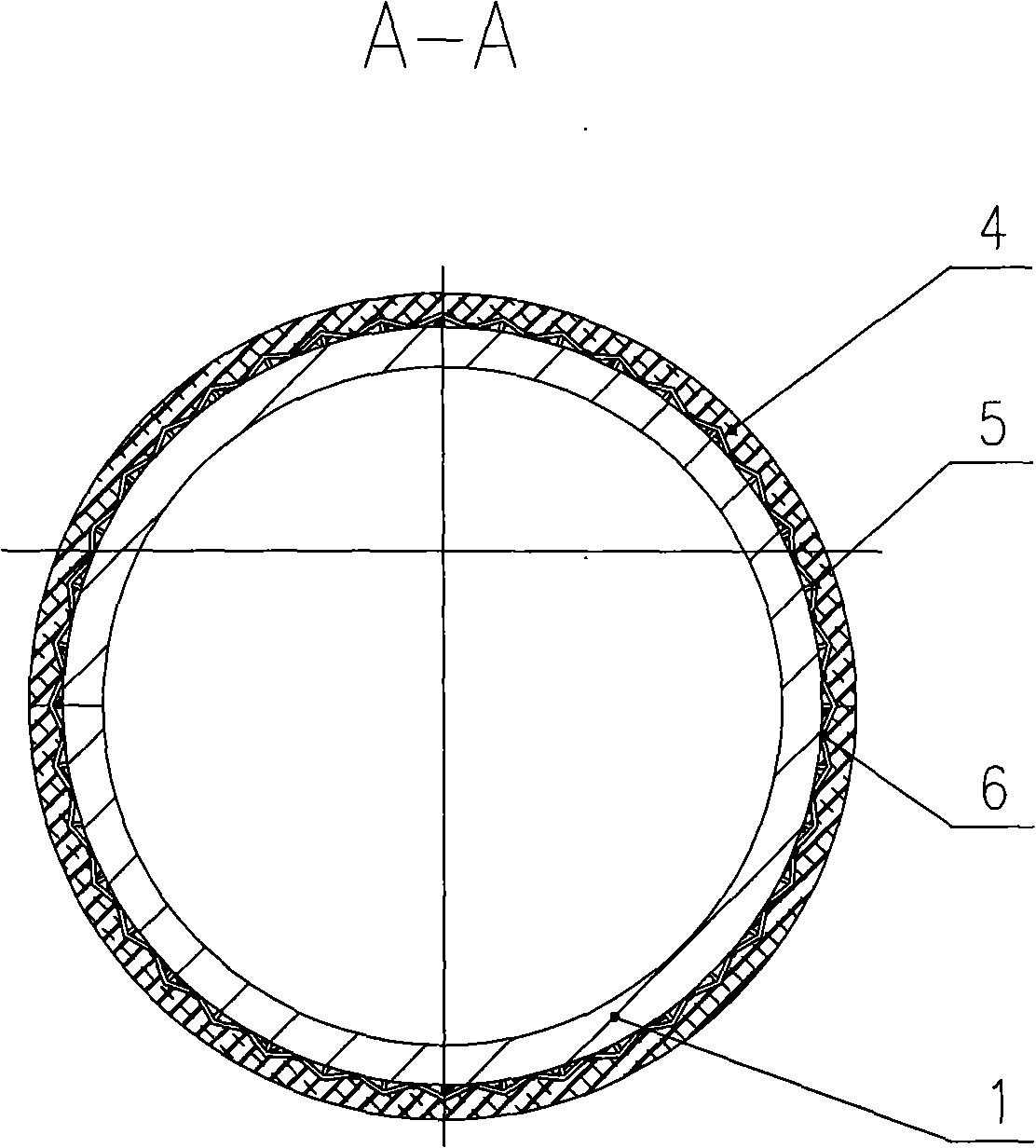

[0020] Such as Figure 1-6 Shown: It mainly includes the stirring shaft 1, the first carbon steel blade 2, the second carbon steel blade 3, the plastic lining layer 4, the metal rhombus steel mesh 5, the metal mesh welding point 6, the motor 7, the reducer 8, the machine Rack 9 and reaction vessel 10 etc.

[0021] In the present invention, the first carbon steel paddle 2 and the second carbon steel paddle 3 are connected to the stirring shaft 1, and the stirring shaft 1 is made of seamless steel pipe. Metal rhombic steel meshes 5 are arranged on the surfaces of the stirring shaft 1 , the first carbon steel paddle 2 and the second carbon steel paddle 3 respectively. The first carbon steel paddle 2 and the second carbon steel paddle 3 have a circular arc transition at the acute angle, and the metal rhombic steel mesh 5 passes through the metal mesh wel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap