Planning method for ion beam polishing path

A polishing path and ion beam technology, applied in the direction of electrical program control, digital control, etc., can solve problems such as long processing time, achieve the effect of improving polishing accuracy and shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

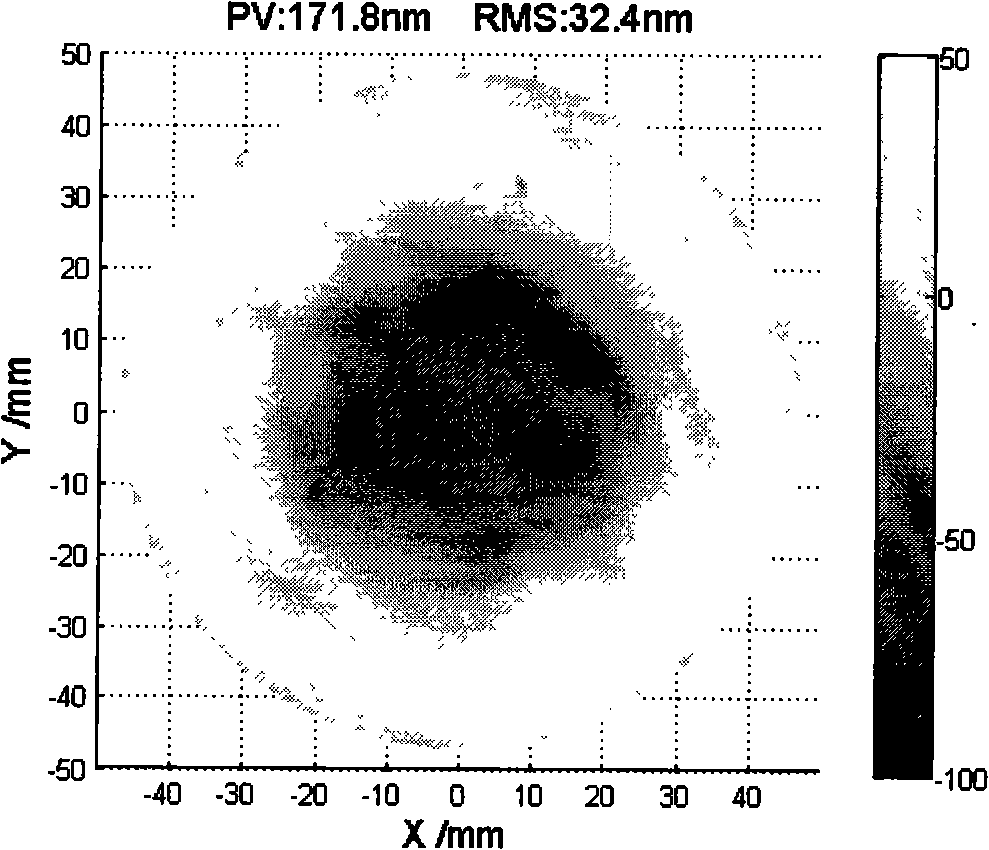

[0024] The ion beam polishing process of this embodiment is carried out on an ion beam polishing equipment, and the process parameters are set as follows: the working gas is argon, and the working vacuum is 0.8×10 -2 Pa, ion energy 1100eV, beam current 25mA. The test workpiece to be polished is ordinary glass-ceramics with a diameter of 100mm.

[0025] The ion beam polishing is carried out to the described glass-ceramics by the following method steps:

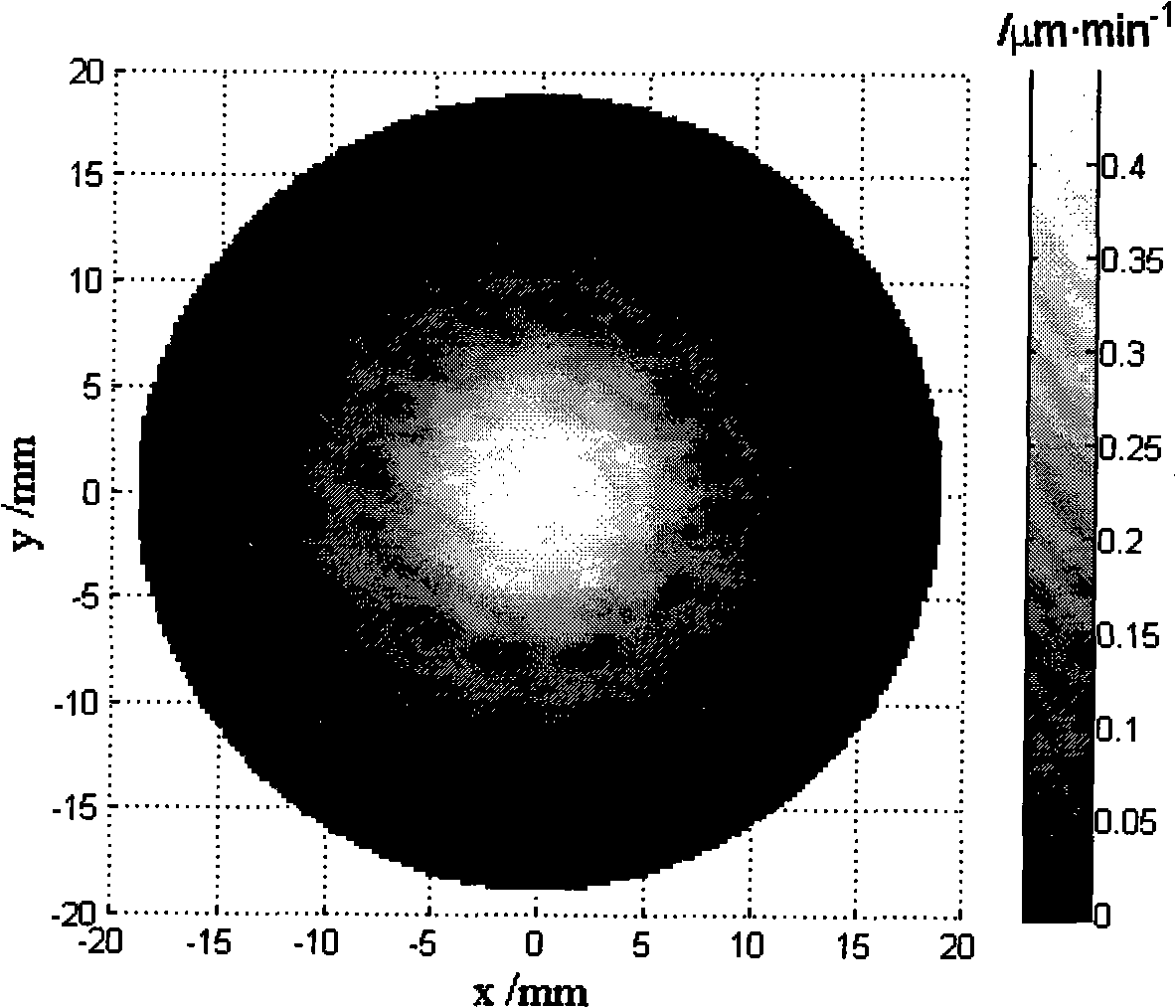

[0026] 1. Determine the removal function: apply the above-mentioned ion beam polishing process to carry out the removal function test, and the obtained removal function is as follows: figure 1 As shown, the diameter of the removal function d=32mm, the volume removal rate v=84μm·mm 2 min -1 ;

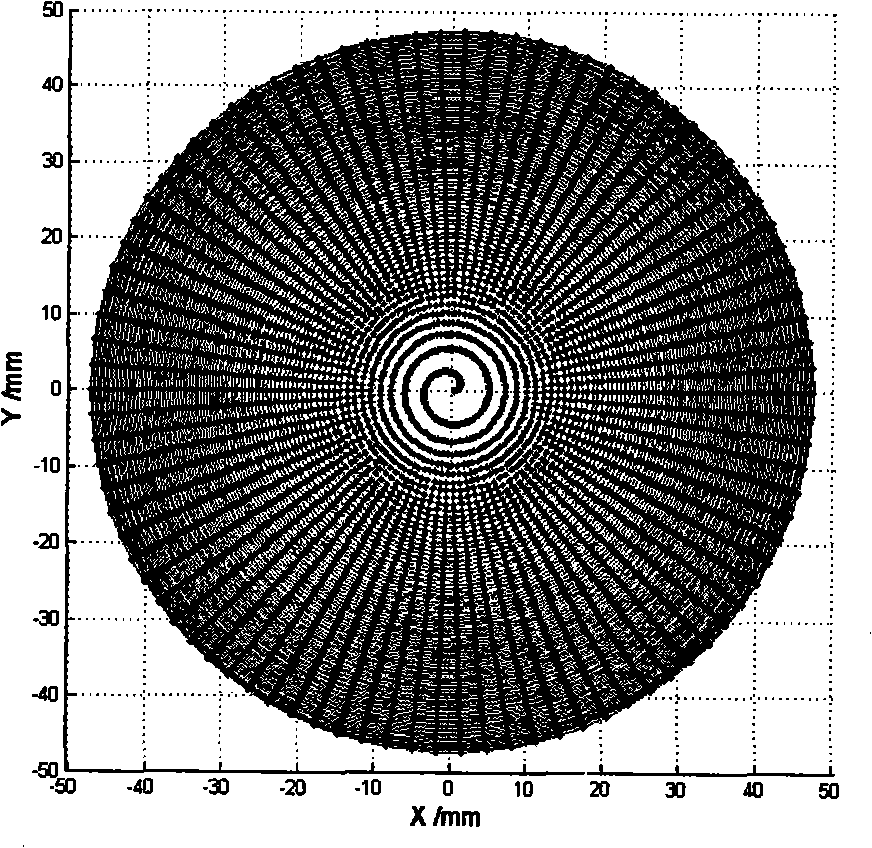

[0027] 2. Establish the polishing path equation: establish the helix equation r=bθ 1 / 2 , where r is the length of the polar axis, θ is the angle of rotation, and b is the helix parameter. Since the removal function diameter d=32mm of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com