Multi-insulated sample local discharge test electrode apparatus

A partial discharge and test electrode technology, applied in the direction of material breakdown voltage, etc., can solve the problems of inability to truly simulate partial discharge of power equipment insulation, complex insulation structure of power equipment, inconsistent test conditions, etc., to improve reliability and objectivity, Increase reliability and objectivity, and ensure the effect of not interfering with each other

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

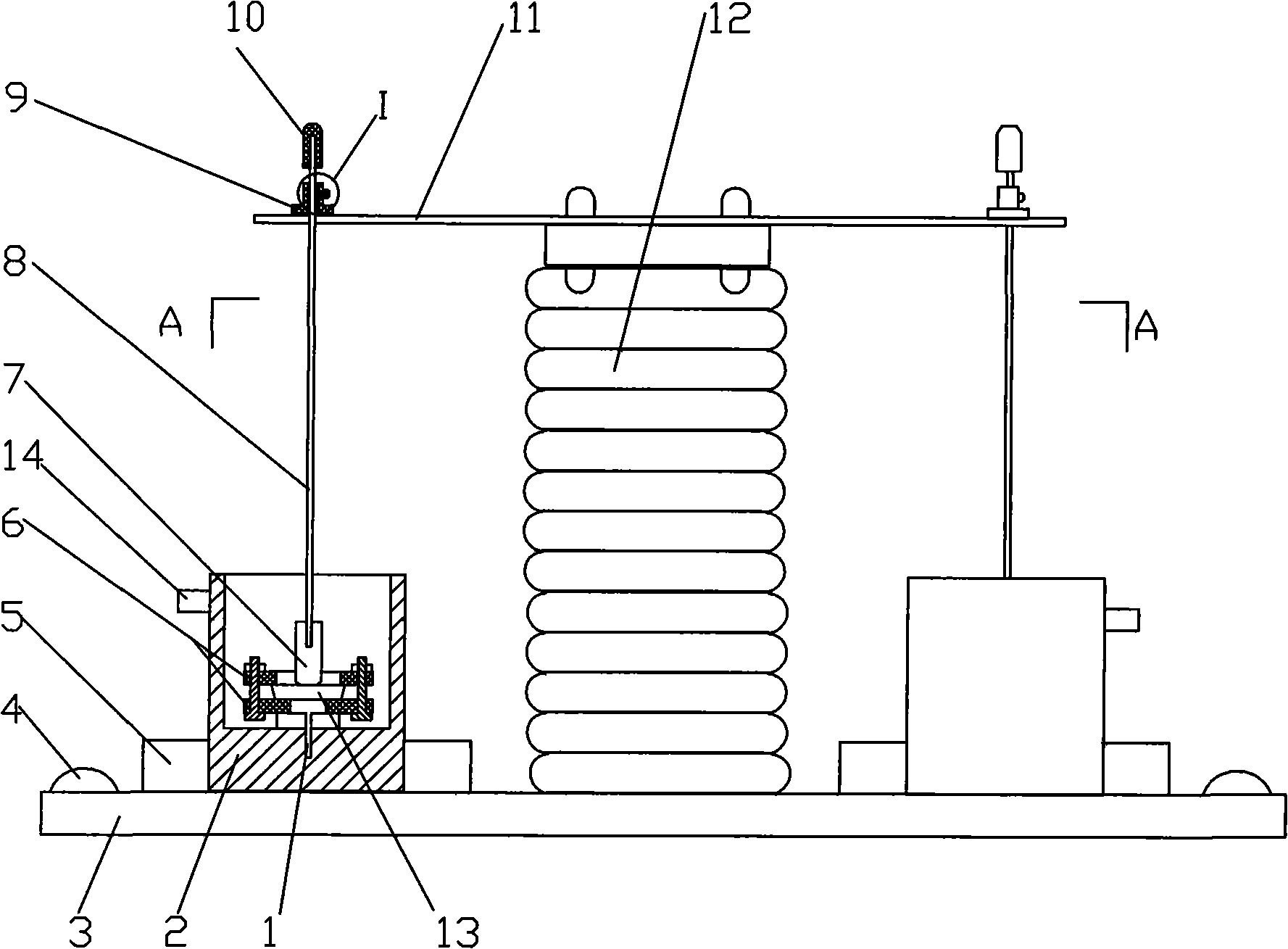

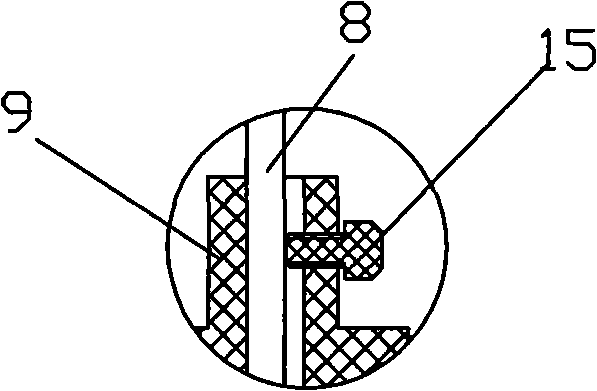

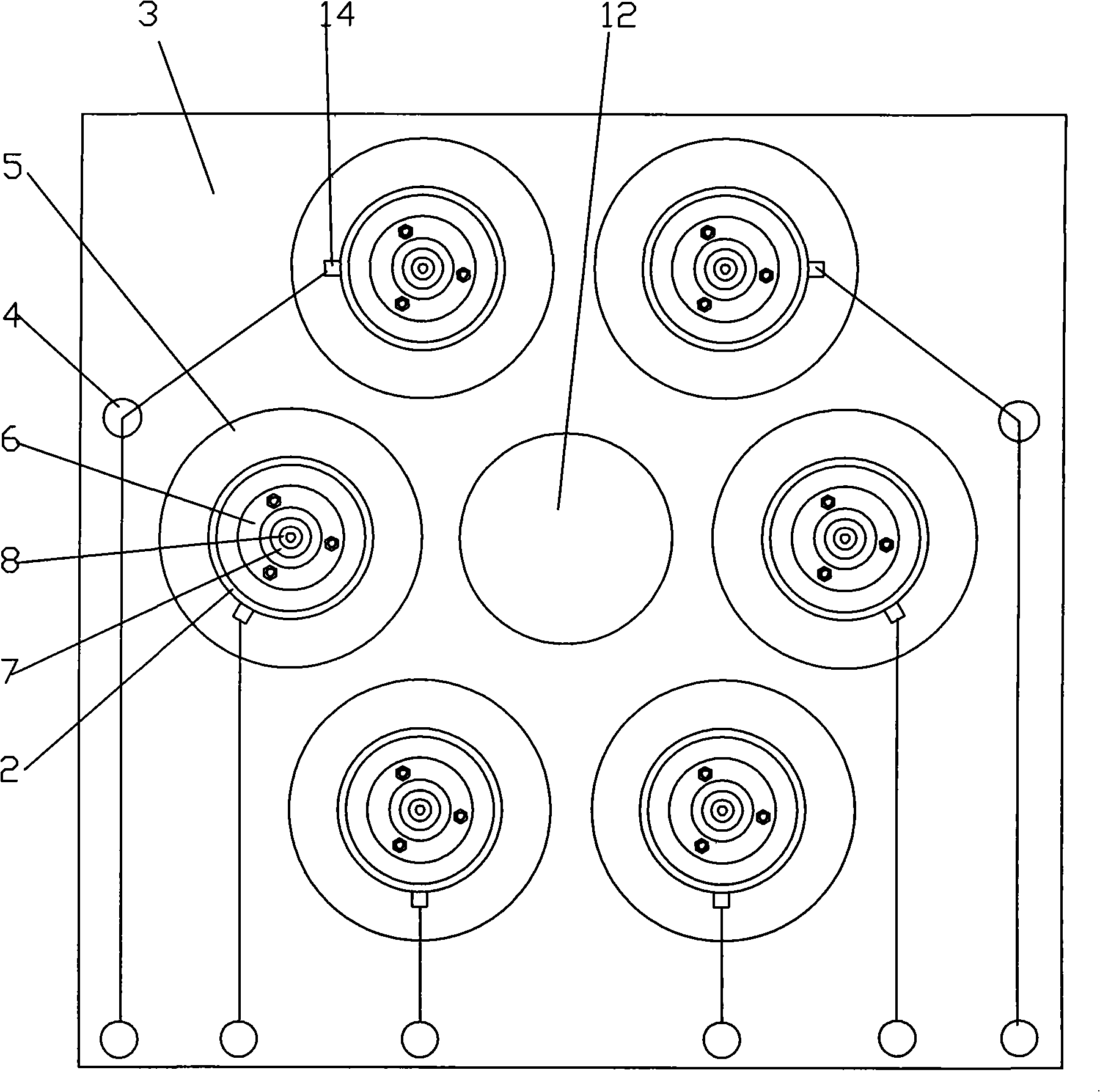

[0020] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 Enlarged view at I, image 3 for figure 1 A sectional view along A-A, as shown in the figure: the multi-insulation sample partial discharge test electrode device of the present embodiment includes a disc-shaped ground electrode 1, a cylindrical high-voltage electrode 7 and a conductive rod 8 connected with the high-voltage electrode 7, and also includes High-voltage electrode plate 11, post insulator 12 and insulating seat plate 3, one end of post insulator 12 is fixedly connected to high-voltage electrode plate 11, and the other end is fixedly connected to insulating seat plate 3; one end of conductive rod 8 passes through high-voltage electrode plate 11, and the high-voltage electrode plate The upper part of 11 bears a bushing 9, and the conductive rod 8 passes through one end of the upper part of the high-voltage electrode plate 11 to fit through the bushing 9, and a tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com