Diffusing plate

A technology of diffuser plate and reflective layer, applied in the field of diffuser plate, to achieve the effect of uniform brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

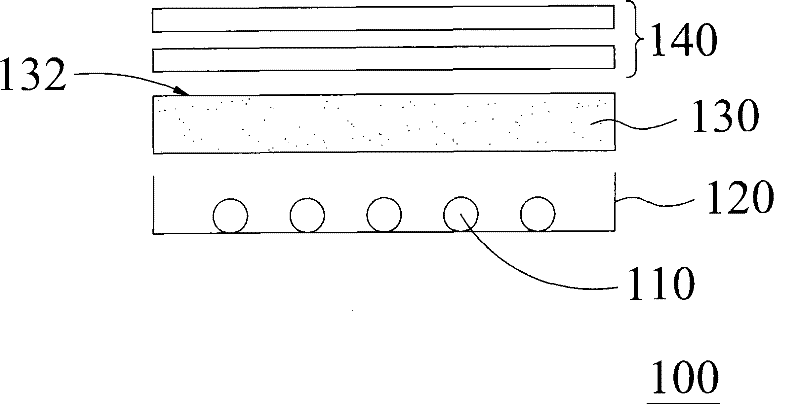

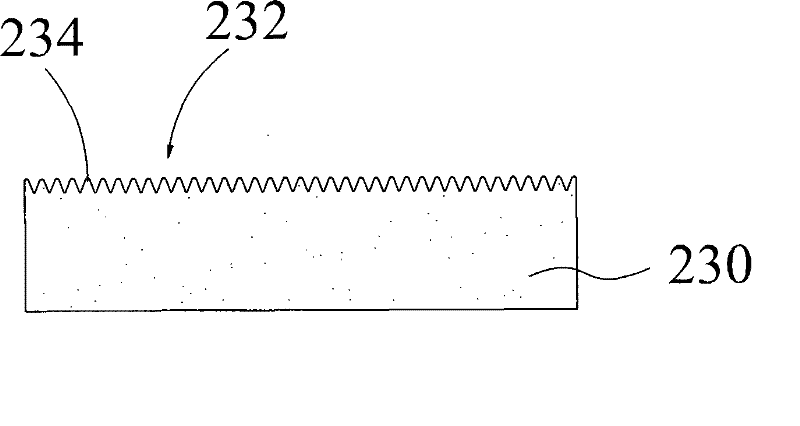

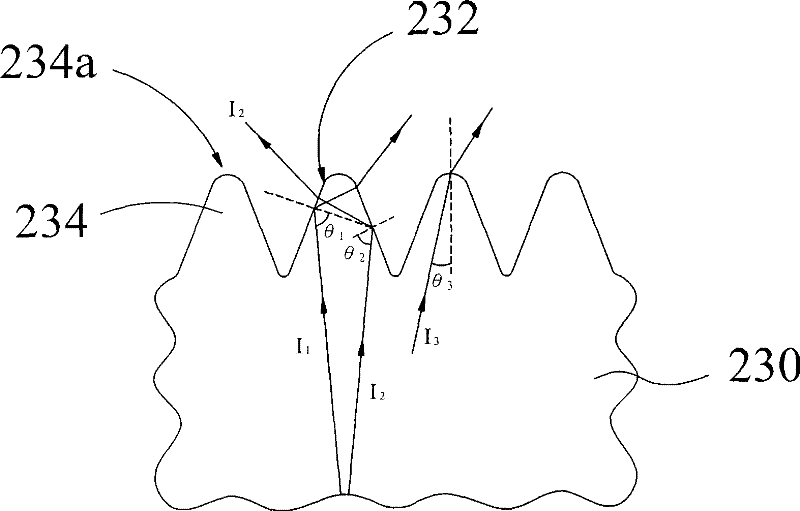

[0040] See Figure 4 , Figure 4 Shown is a backlight module of this embodiment. The backlight module 300 includes a light-emitting source 310, a reflective cover 320, a diffuser 330, and a plurality of optical films 340. The light-emitting source 310 is a cold cathode fluorescent tube in this embodiment. Of course, those of ordinary skill in the art can also use light-emitting diodes ( LED) to replace cold cathode fluorescent tubes. The reflector 320 has light-reflecting properties, and the diffuser plate 330 is made of a polymer light-transmitting material. The polymer light-transmitting material is, for example, polymethyl methacrylate (PMMA) or polymethylmethacrylate. Styrene (Poly Styrene, referred to as PS). In addition, the inside of the diffusion plate 330 may be doped with light diffusion particles or ultraviolet absorbers, for example. The optical film 340 is, for example, a Brightness Enhancement Film or a Diffusion Film. The function of the Brightness Enhancement ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com