Defect mending apparatus and target material structure

A defect repairing and repairing material technology, applied in the field of defect repairing devices, can solve problems such as damage, material oxidation, and repairing material bearing unit substrate damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to have a further cognition and understanding of the features, purposes and functions of the present invention, the relevant detailed structure and design concept of the device of the present invention will be explained below, so that the review committee can understand the characteristics of the present invention, and explain in detail The description states the following:

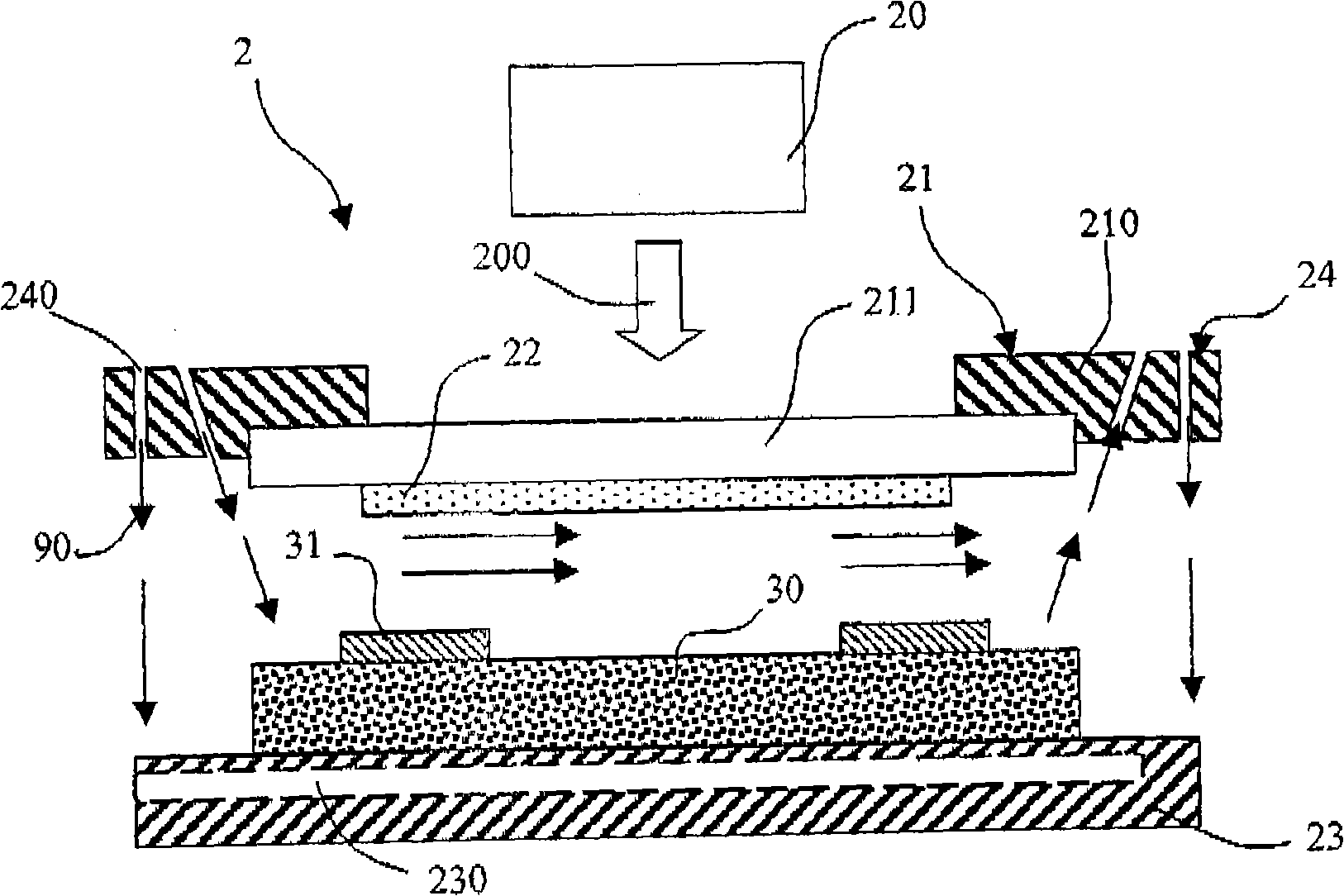

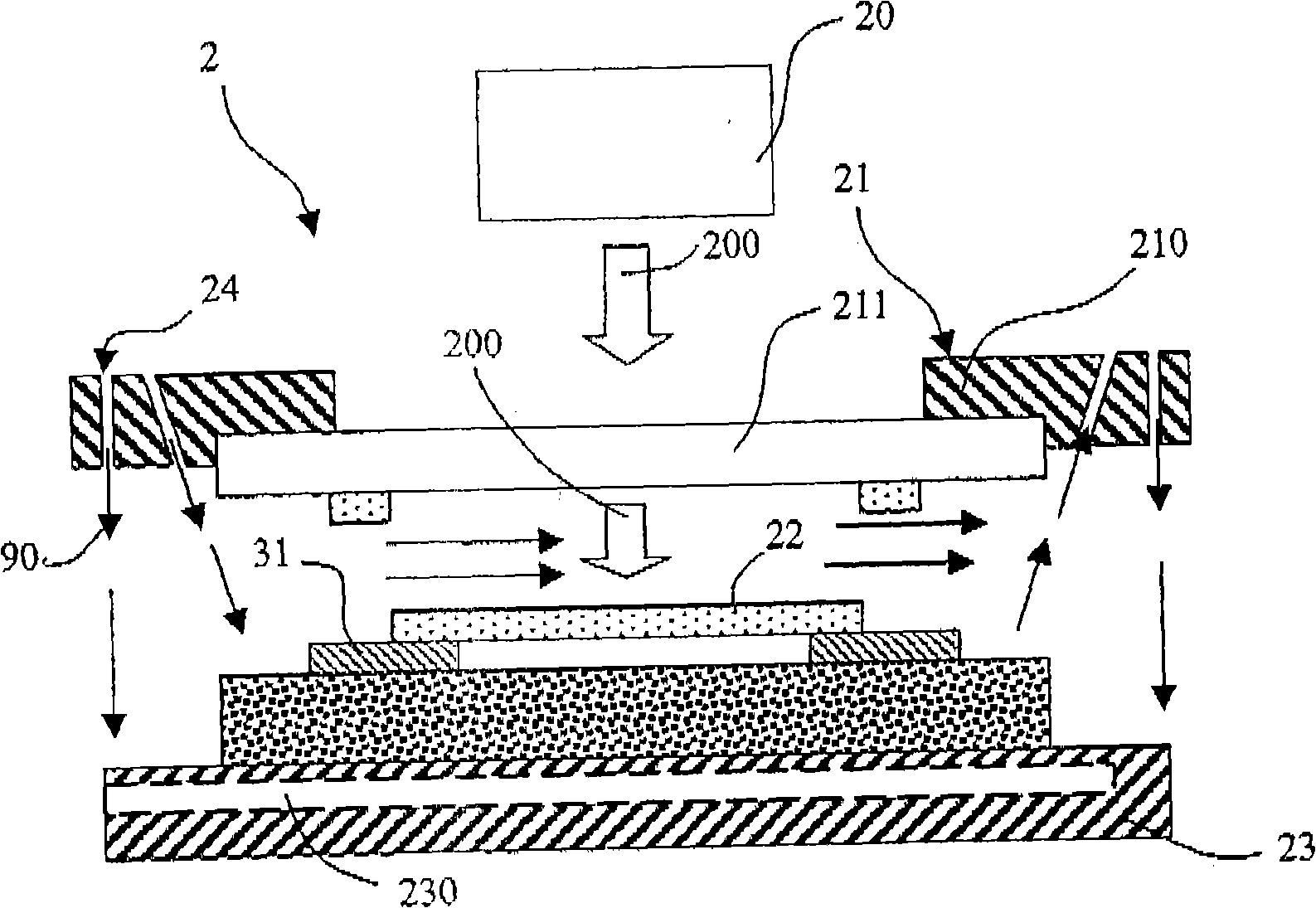

[0051] see Figure 2A and Figure 2B As shown, this figure is a schematic diagram of the first embodiment of the defect repairing device of the present invention. The defect repairing device 2 has an electromagnetic wave emitting unit 20 , a platform 23 , a carrying unit 21 and a fluid cooling unit. The electromagnetic wave emitting unit 20 can generate an electromagnetic wave beam 200, which can be selected as a full-band laser source or an ultraviolet light wave laser. In this embodiment, the electromagnetic wave emitting unit 20 is a full-band laser source.

[0052] The platform 23 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com