Workpiece reference point detection method and process apparatus using same

A processing device and detection method technology, which is applied in the direction of measuring devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of multi-time, edge position detection accuracy, increasing the number of multiple coordinate data, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

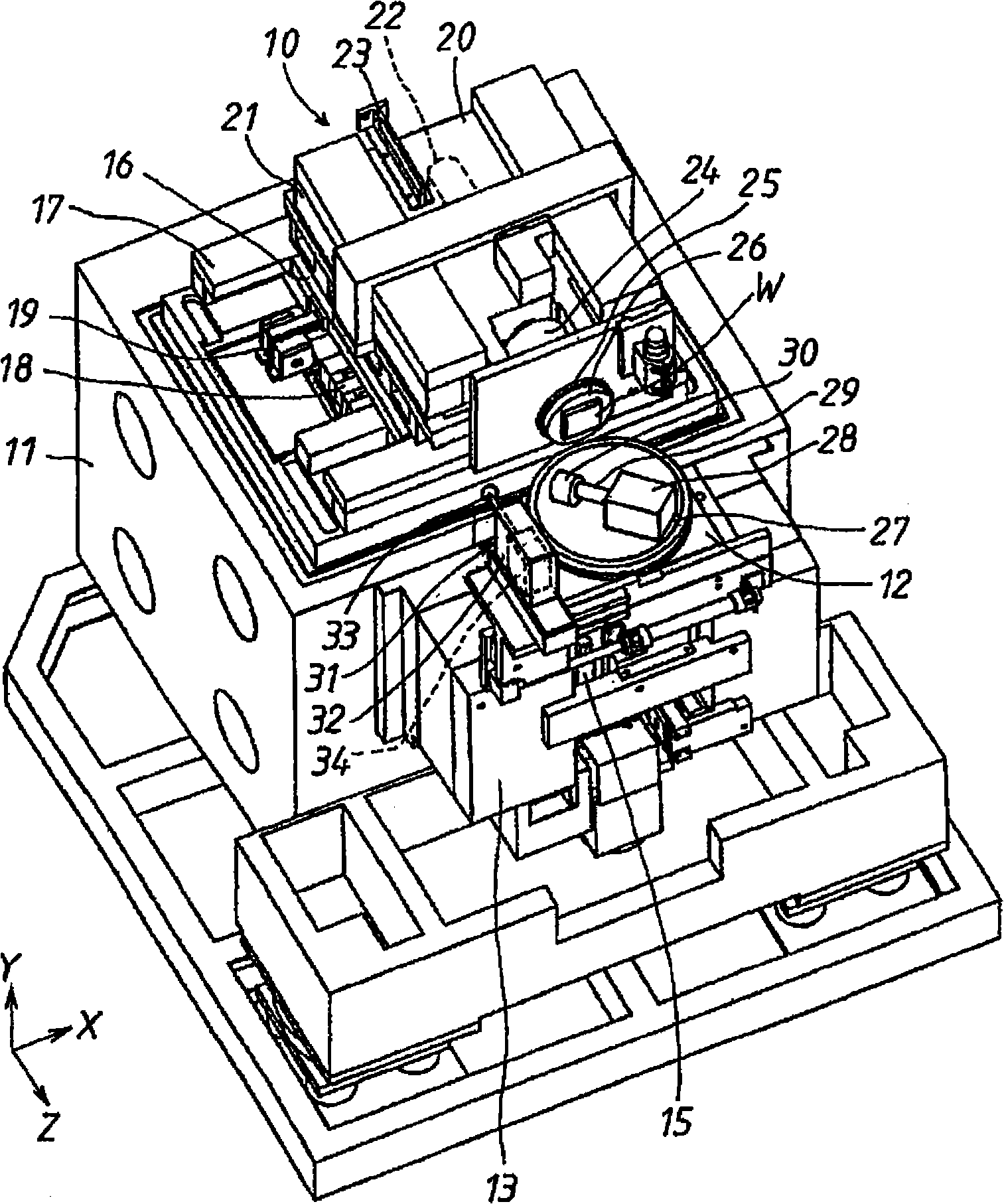

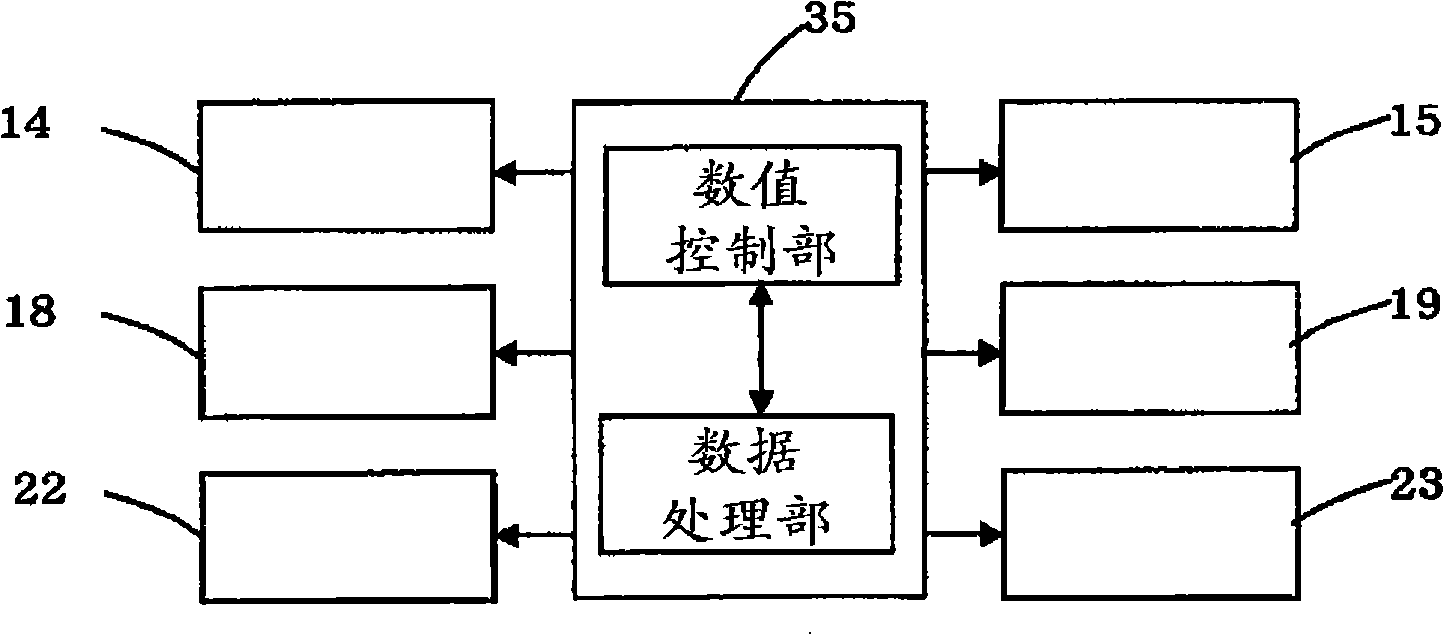

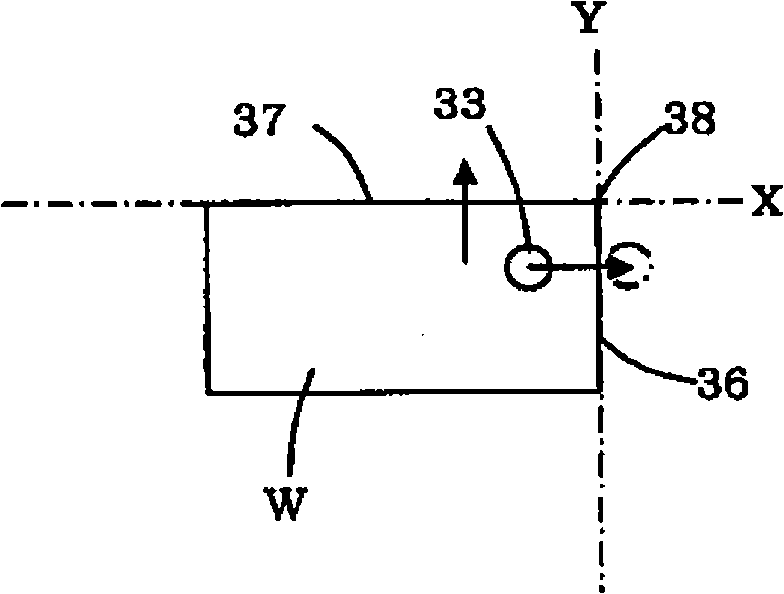

[0032] Hereinafter, a workpiece reference point detection method according to an embodiment of the present invention and a processing apparatus using the method will be described based on the drawings. exist figure 1 Among them, the Y-axis slide table 12 is erected in front of the head 11 of the ultra-precision machining device 10 so that it can move linearly in the vertical Y-axis direction through the guide mechanism 13 . The Y-axis slide table 12 utilizes a linear motor 14 (refer to figure 2 ) moves linearly along the Y-axis direction, and detects the amount of movement through the linear displacement sensor 15, so as to obtain feedback for position control.

[0033] The X-axis slide table 16 is erected on the horizontal surface of the head 11 so as to be linearly movable in the left and right X-axis directions through the guide mechanism 17 . The X-axis slide table 16 linearly moves along the X-axis direction by a linear motor 18 , and detects the movement amount by a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com