Weighted vertical type ring rolling mill

A ring rolling machine, vertical technology, applied in the direction of metal rolling, metal rolling, metal processing equipment, etc., can solve the problem of low quality ring rolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

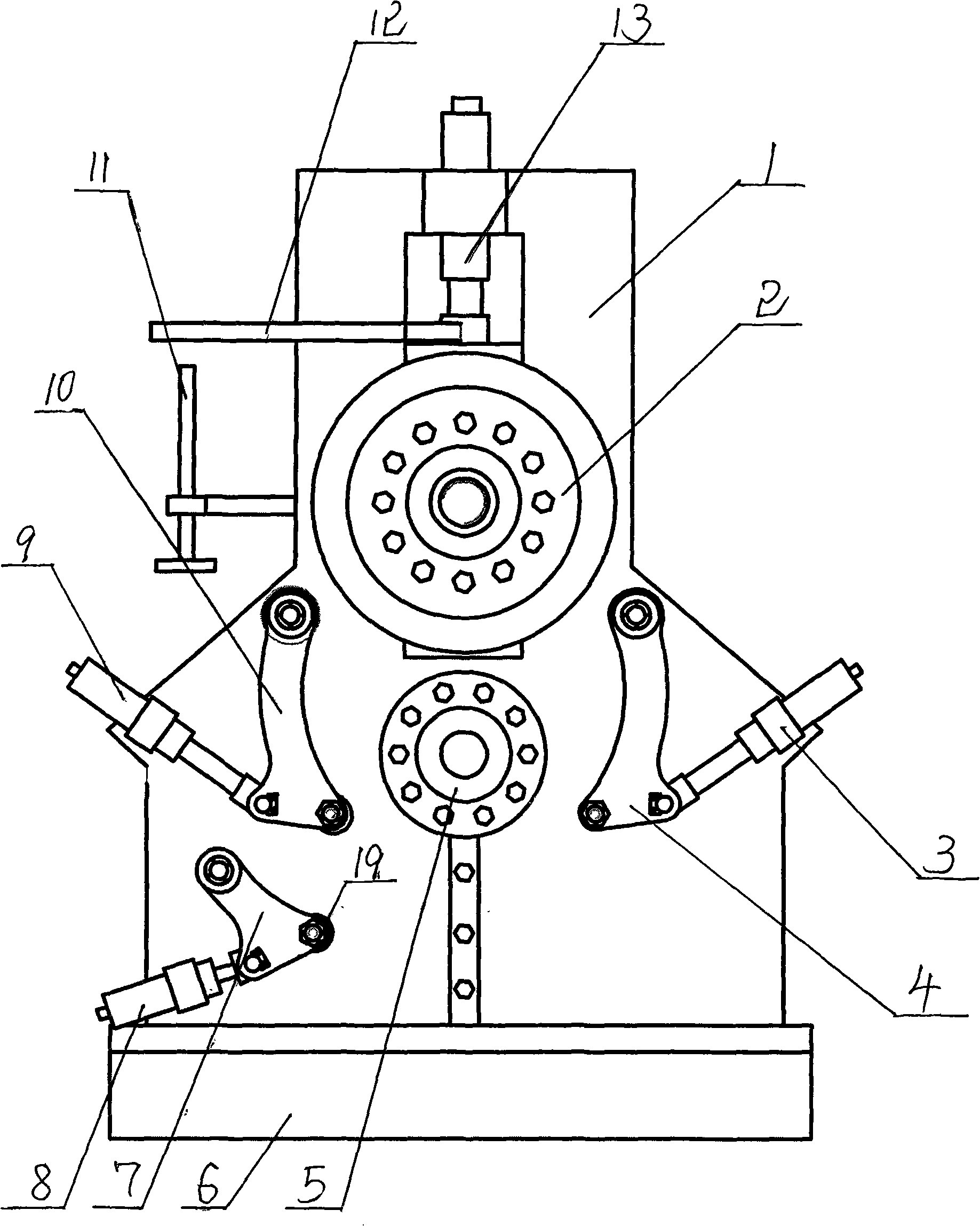

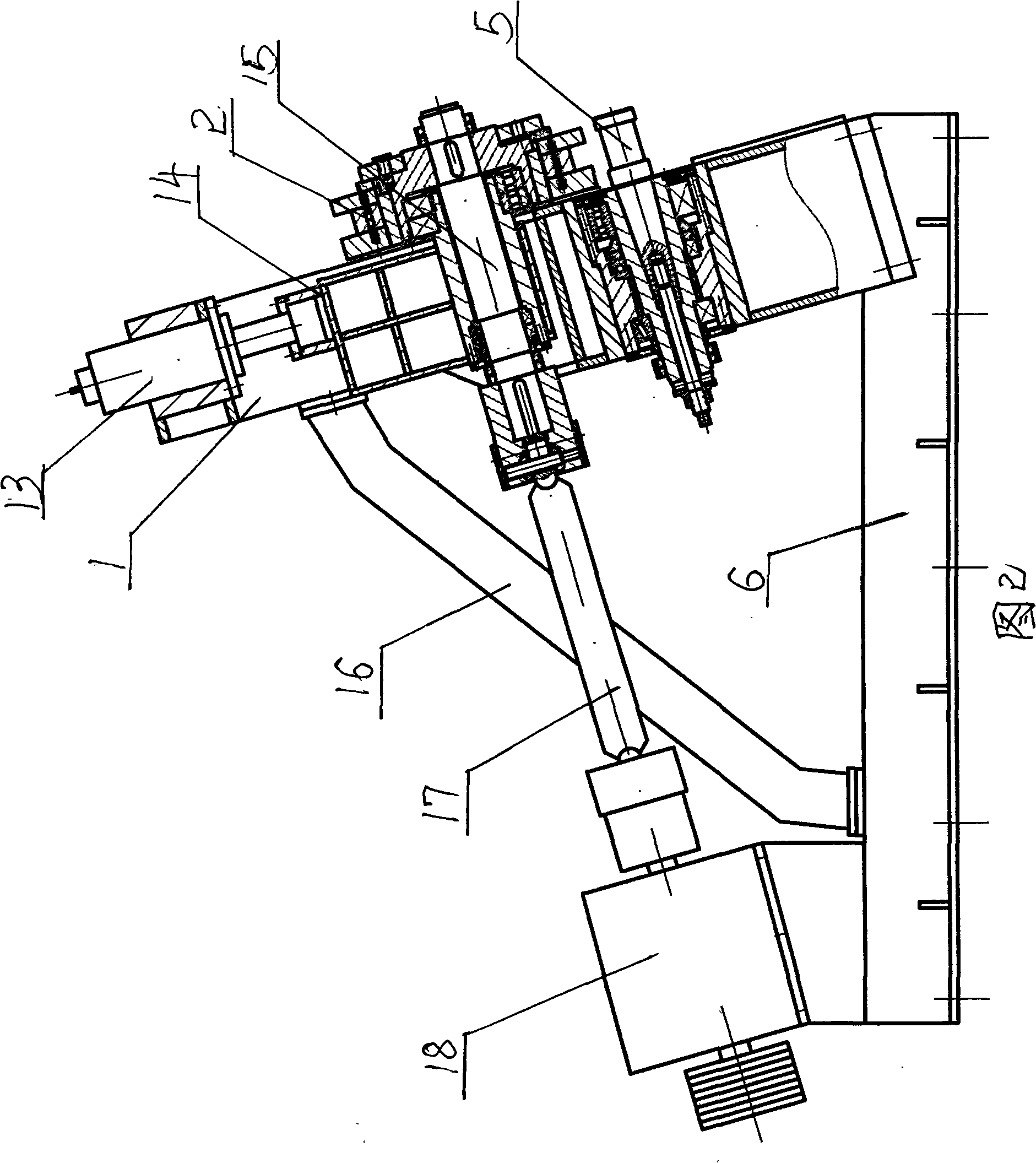

[0012] Such as figure 1 As shown in , 2, a kind of weighting vertical ring rolling machine comprises a base 6, a vertical workbench 1 and a motor 18 are arranged on the base 6, the vertical workbench 1 is provided with a rotating main mold 2, and the rotating main mold 2 The main shaft 15 is connected with the motor 18 through the shaft coupling 17, the mandrel 5 is arranged under the rotating main mold 2, the holding rollers 10, 4 are arranged on both sides of the rotating main mold 2, and the limit position is arranged above the rotating main mold 2 Device, is provided with the distance measuring device 7 that has distance measuring wheel 19 below the side of rotating master mold 2.

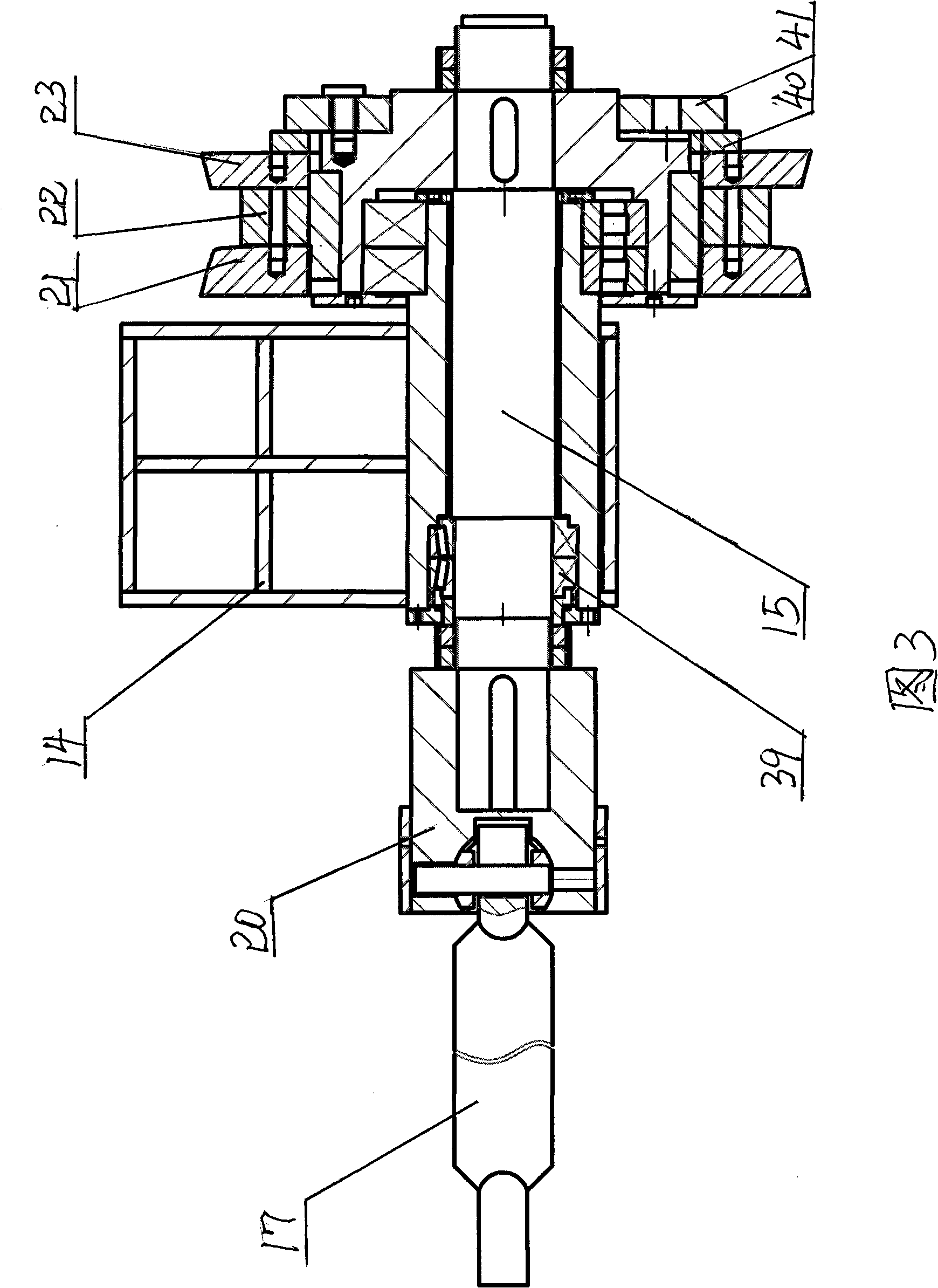

[0013] As shown in Figure 3, the main shaft 15 of the rotating main mold 2 is covered with a main shaft seat 14, and the main shaft seat 14 is installed on the vertical workbench 1, and the upper end is connected with a pressure oil cylinder 13. A bearing 39 is arranged between the main shaft ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com