Supercharging pulp feeding system of coal water slurry fuel and method thereof

A coal-water slurry and slurry supply technology, which is applied in fuel supply, combustion equipment, lighting and heating equipment, etc., can solve the problems of no buffer, accelerated screw pump wear, and increased motor revolutions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Referring to the accompanying drawings, specific embodiments of the present invention will be described in detail below.

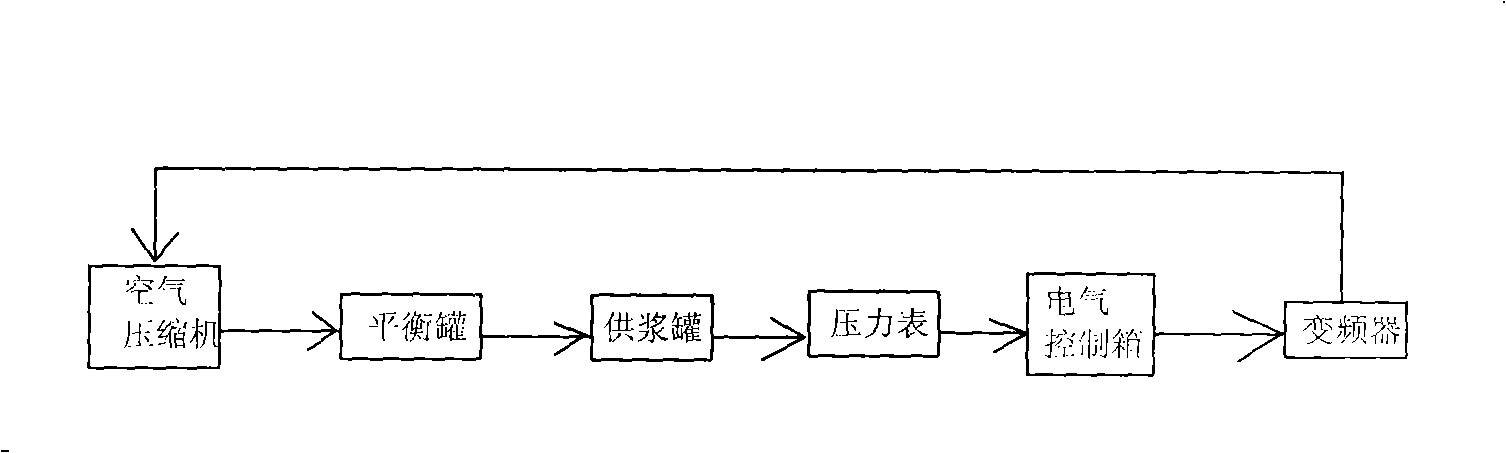

[0010] figure 1 It is a schematic diagram of the basic principle of the present invention. The pressurized slurry supply system of the coal-water slurry fuel of the present invention comprises an air compressor connected in sequence, a balance tank, and a slurry supply tank, a pressure gauge is arranged on the slurry supply tank, and an electric control box (not shown in the figure) is also provided output) and a frequency converter (not shown in the figure), the signal of the pressure gauge is input into the electrical control box, and the electrical control box outputs a frequency signal to the frequency converter, and the frequency signal controls the speed of the air compressor. The inverter can use the model FRN5.5G11S-4CX.

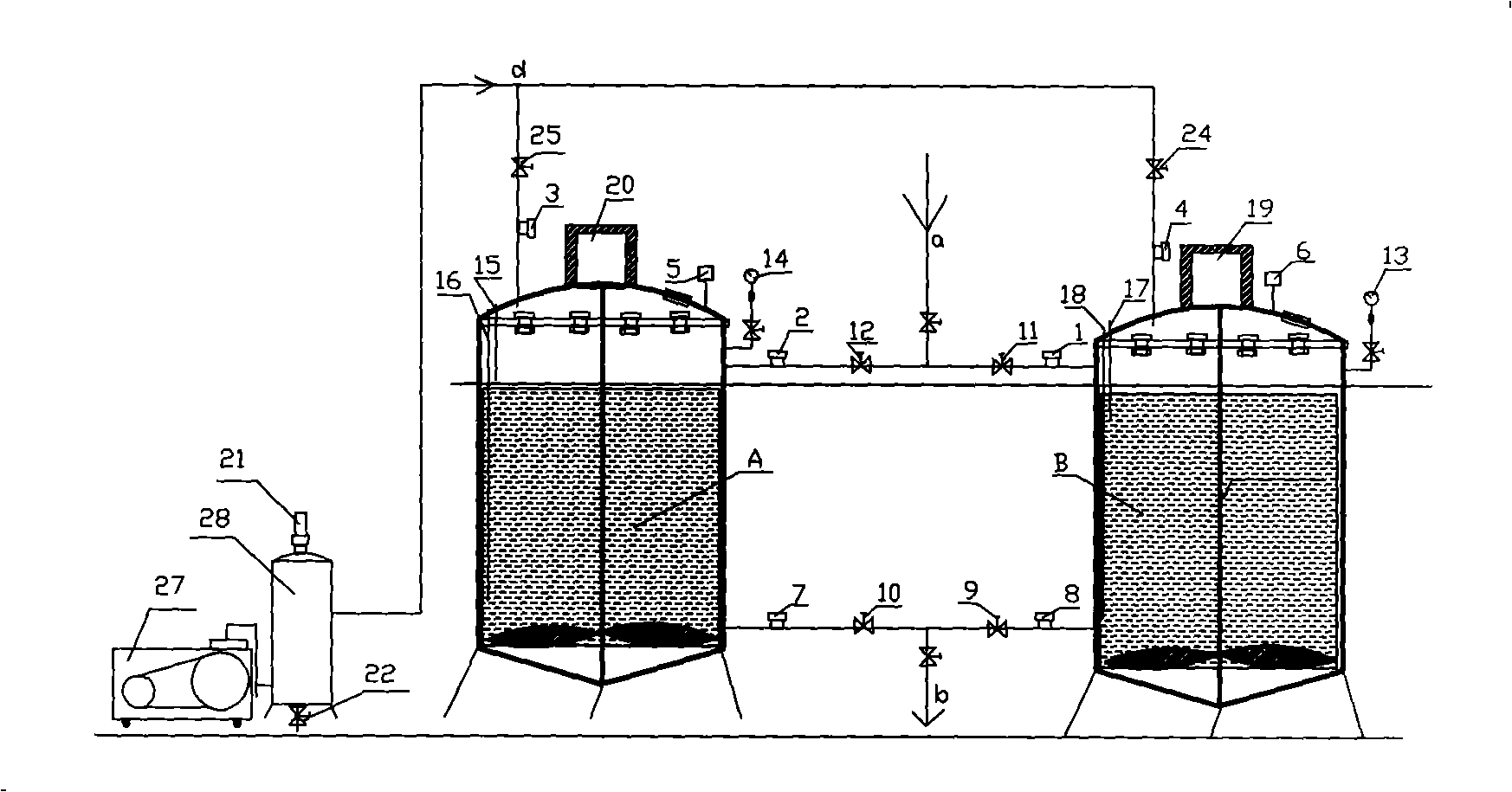

[0011] figure 2 It is an overall structure diagram of the present invention. Because the coal-water slurry will cau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com