Torsion-detecting sleeve member and torque-detecting device using the same

一种套筒部件、检测装置的技术,应用在测量装置、转矩计量、自行车附件等方向,能够解决测定误差、难以变更扭力检测范围等问题,达到抑制测定误差的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

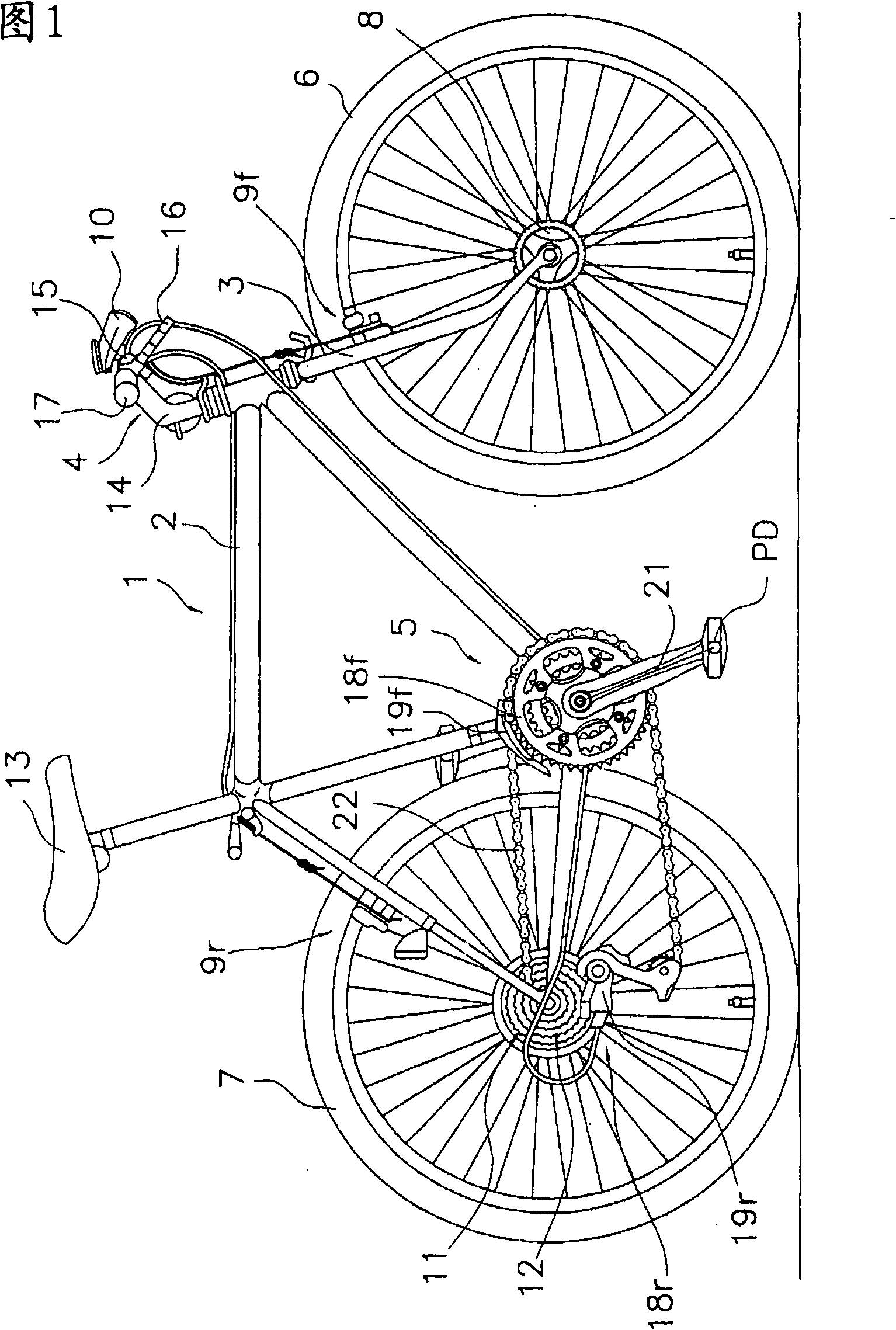

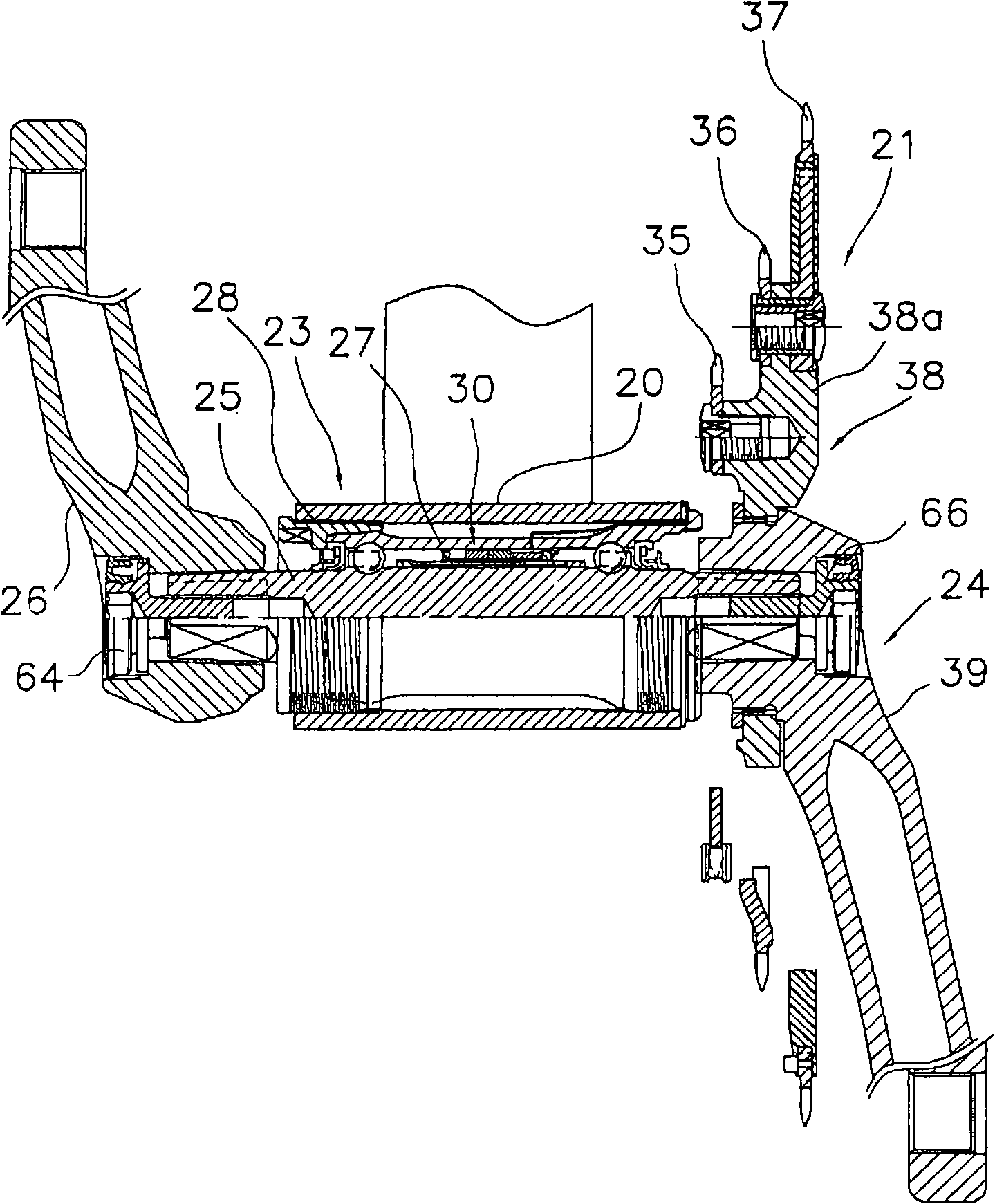

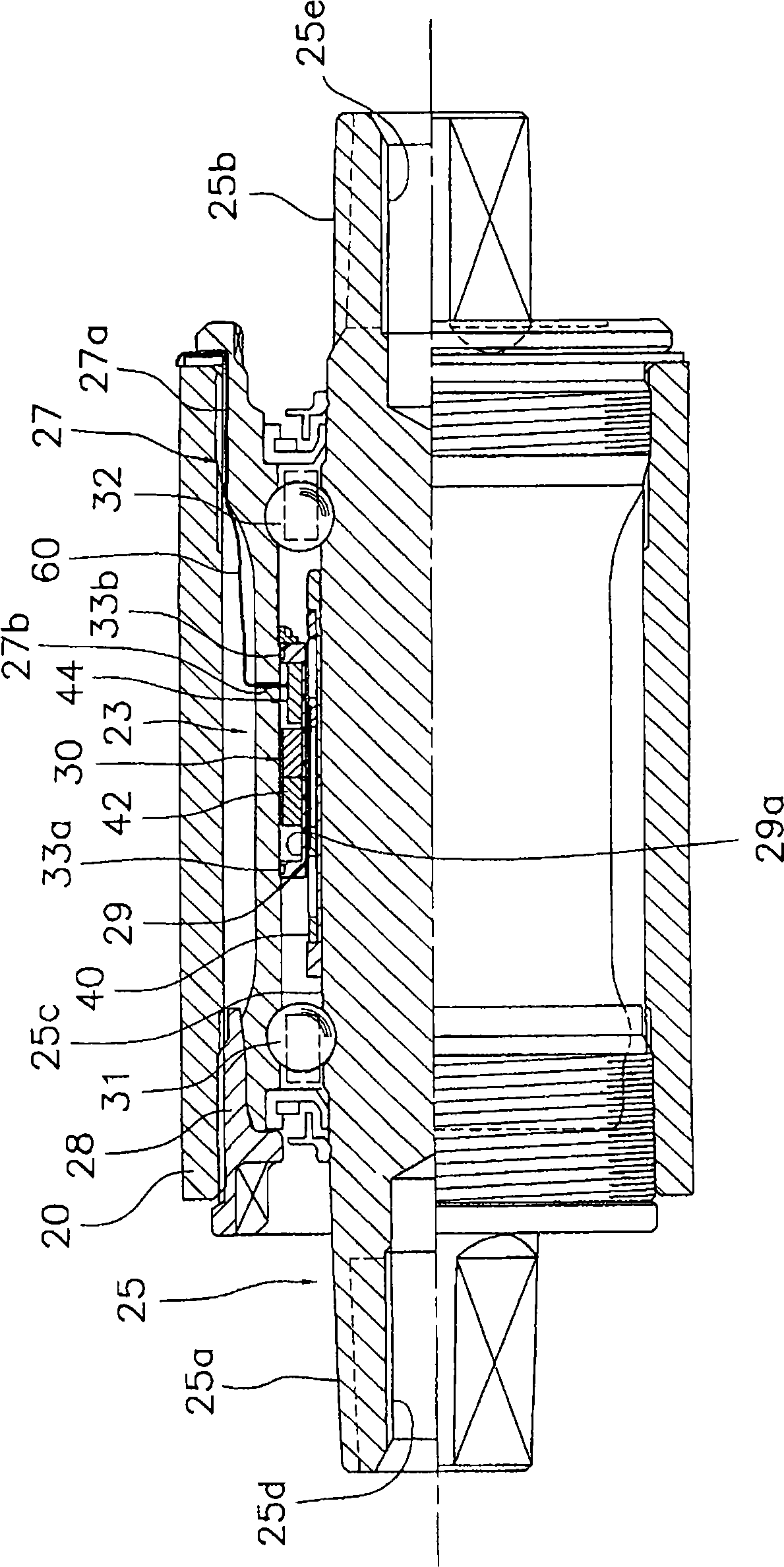

[0055] In FIG. 1 , the bicycle to which the first embodiment of the present invention is applied is a bicycle called a mountain bike that can run on uneven ground. The bicycle has a vehicle frame 1, a handlebar part 4, a driving part 5, a front wheel 6 on which a hub dynamo 8 is mounted, a rear wheel 7, front and rear brake devices 9f, 9r, and the vehicle frame 1 has a diamond-shaped frame body 2 and fork 3. A headlight 10 with a bicycle computer for illuminating the front of the bicycle is attached to the handlebar portion 4 .

[0056] The frame body 2 of the frame 1 is manufactured by welding tubes. Each part including the seat 13 and the driving part 5 is attached to the frame body 2 . The front fork 3 is mounted on the front of the frame body 2 so as to be freely swingable around an inclined axis.

[0057] The handlebar unit 4 has a handlebar 14 fixed to the upper portion of the front fork 3 and a handlebar 15 fixed to the handlebar 14 . At both ends of the handlebar h...

no. 2 approach

[0087] In the first embodiment, the present invention was described by taking as an example the crank assembly 21 in which the gear crank 24 and the left crank 26 are detachably fixed to both ends of a solid crankshaft 25 by the fixing bolts 66 , 64 . In the second embodiment such as Figure 7 As shown, the case where the present invention is applied to the crank assembly 121 in which the gear crank 124 is integrally fixed to one end of the crank shaft 125 will be described. In addition, the crankshaft may be fixed integrally with the left crank.

[0088] exist Figure 7 Among them, the crank assembly 121 has a crank assembly 123 including a crank shaft 125, a gear crank 124 integrally fixed, for example, by riveting, to the right end of the crank shaft 125, and a fixed bolt 164, which is detachably fixed to the crank shaft 125. The left crank 126 at the left end.

[0089] The gear crank 124 has, for example, two sprockets 135 and 137 arranged side by side in the axial dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com