Electromagnetic wave absorbability plastic foam board

A plastic foam and absorbent technology, applied in the field of electromagnetic wave absorbers, can solve the problems of high cost, unfavorable industrialization development, complicated preparation process, etc., and achieve the effect of light weight, low production cost and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

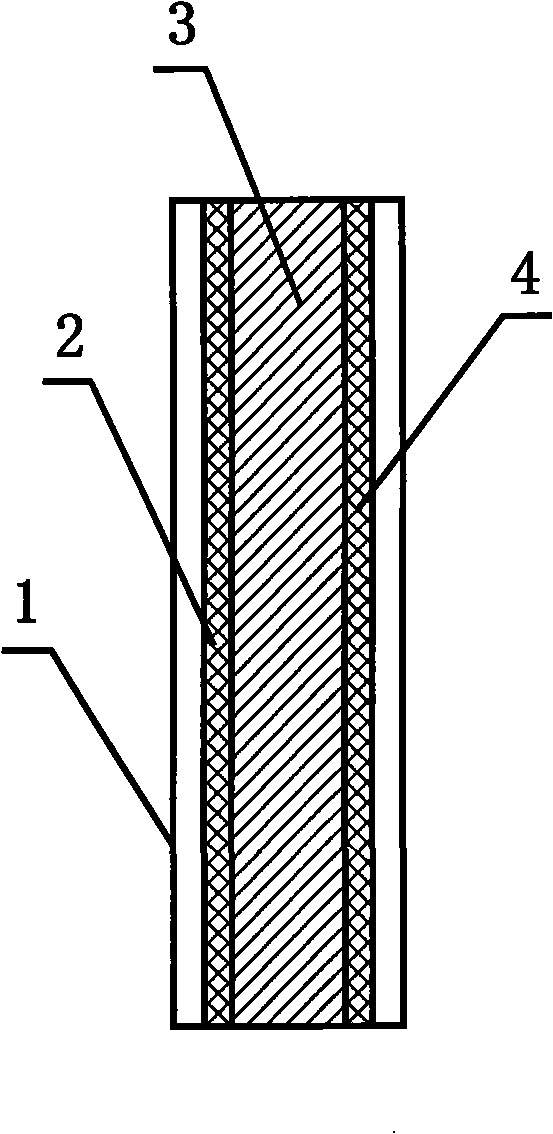

[0019] Use commercially available plastic foam board with a thickness of 20mm. Then on both sides of the board, use adhesive to compound resistive film (area resistance 370Ω□, thickness 0.05mm), conductive film (area resistance 2Ω□, thickness 0.03mm), and then glue on the surface of the resistive film and conductive film. The binding agent pressure composites a protective film, and the protective film is ordinary wall paper (thickness 0.07mm) to obtain a pure density board electromagnetic wave absorber. The absorption effect is 2-5GHz band, the overall absorption is basically above 5dB, and the maximum absorption is 24dB.

Embodiment 2

[0021] Use commercially available plastic foam board with a thickness of 20mm. Then on both sides of the board, use adhesive to compound the resistive film (area resistance 340Ω□, thickness 0.05mm) and conductive film (area resistance 2Ω□, thickness 0.03mm), and then glue on the surface of the resistance film and the conductive film. The binding agent pressure composites a protective film, and the protective film is ordinary wall paper (thickness 0.07mm) to obtain a pure density board electromagnetic wave absorber. The absorption effect is 2-5GHz band, the overall absorption is basically above 5dB, and the maximum absorption is 20dB.

Embodiment 3

[0023] Use commercially available plastic foam board with a thickness of 20mm. Then on both sides of the board, use adhesive to compound resistive film (area resistance 430Ω□, thickness 0.05mm) and conductive film (area resistance 2Ω□, thickness 0.03mm), and then glue on the surface of the resistive film and conductive film. The binding agent pressure composites a protective film, and the protective film is ordinary wall paper (thickness 0.07mm) to obtain a pure density board electromagnetic wave absorber. The absorption effect is in the 2-5GHz frequency band, the overall absorption is basically above 5dB, and the maximum absorption is 22dB.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com