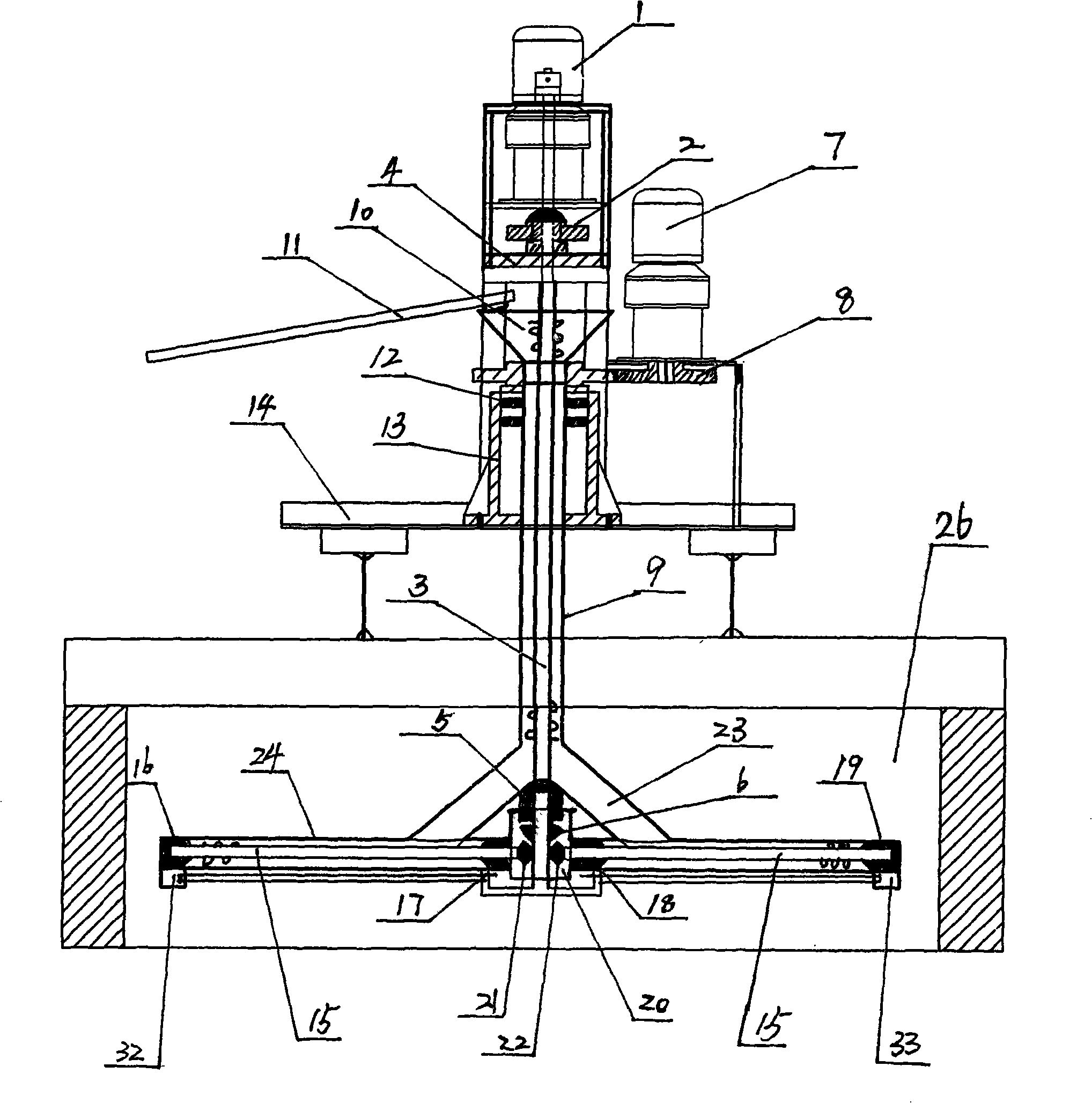

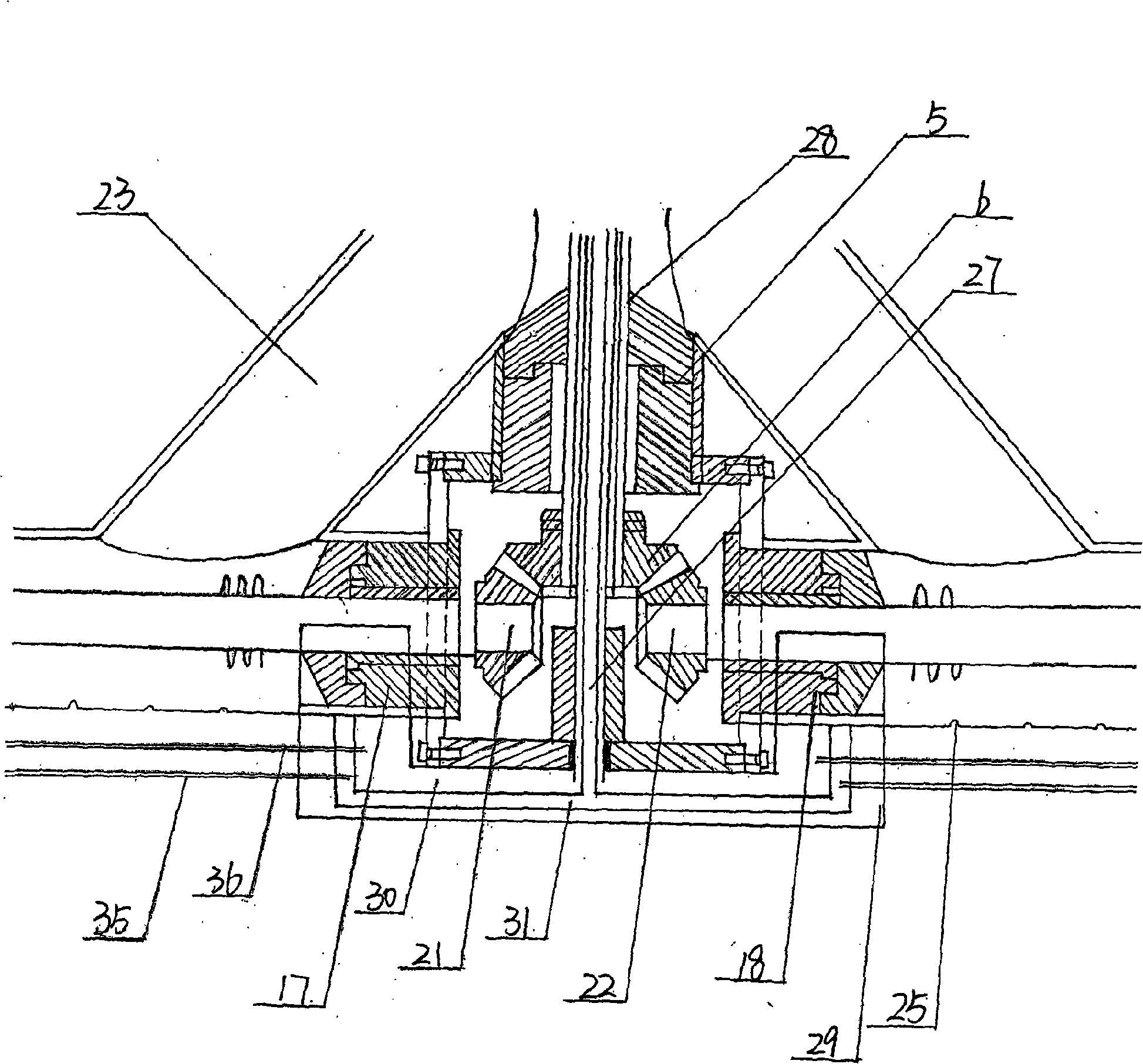

Material-strewing device of all-electric hexagonal glass Melting Furnace

A material spreading device, hexagonal technology, applied in the field of material spreading device, can solve problems such as easy caking, body injury, liquid level fluctuation, etc., achieve the effect of reducing strength, avoiding caking, and stabilizing output

Inactive Publication Date: 2008-10-15

JIANGSU JIUDING NEW MATERIAL CO LTD

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the feeding process of the all-electric fused glass fiber kiln, the traditional method is to directly add the material to the kiln through the feeding mechanism, resulting in excessive concentration of raw materials in the kiln, which is easy to agglomerate, and they need to be dispersed manually. Not only will it take a long time, but it will also cause fluctuations in the liquid level, which will affect the quality and output of the wire drawing. In severe cases, it will not be able to produce, and the effect is very bad. Moreover, due to the high temperature of the kiln pool, usually at 1200°C-1400°C, Working on the side of the kiln for a long time will bring harm to the body

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a spreader for an all-electric hexagonal glass-fiber tank furnace. The spreader comprises a vertical feeding pipe, a distributing pipe, a horizontal feeding pipe, a circulating water pipe, a feeder, a gear case, a motor and a water drum; and utilizes the motor to drive a main screw pole and a horizontal screw pole as well as the whole mechanism to rotate, thus, the raw material can be fast and evenly spread in the tank furnace, and the level fluctuation in the tank cannot be caused, thereby avoiding caking, guaranteeing the quality of the fiber drawing and the stability of the production, and greatly reducing the intensity of manual labor; adopting the water drum and circulating water can effectively protect a bearing and gears, thereby enabling the bearing and the gears to be high temperature resistant and have long service lives.

Description

A material spreading device for all-electric melting hexagonal fiberglass kiln pool technical field The invention relates to a material spreading device, in particular to a material spreading device for an all-electric fusion hexagonal glass fiber kiln pool. Background technique In the feeding process of the all-electric fused glass fiber kiln, the traditional method is to directly add the material to the kiln through the feeding mechanism, resulting in excessive concentration of raw materials in the kiln, which is easy to agglomerate, and they need to be dispersed manually. Not only will it take a long time, but it will also cause fluctuations in the liquid level, which will affect the quality and output of the wire drawing. In severe cases, it will not be able to produce, and the effect is very bad. Moreover, due to the high temperature of the kiln pool, usually at 1200°C-1400°C, Working by the kiln pool for a long time will bring harm to the body. Contents of the inve...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C03B3/00

Inventor 姜鹄徐建如范崇明沈达泉章志勇袁建东姜鸿全

Owner JIANGSU JIUDING NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com