Manufacturing method for heat radiating base of surface adhesive diode support and construction thereof

A surface-mounted, heat-dissipating base technology, applied in semiconductor/solid-state device manufacturing, heat exchange equipment, electrical components, etc., can solve the problems of increased process, limited, inability to respond flexibly, etc., to improve heat dissipation and improve convenience. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

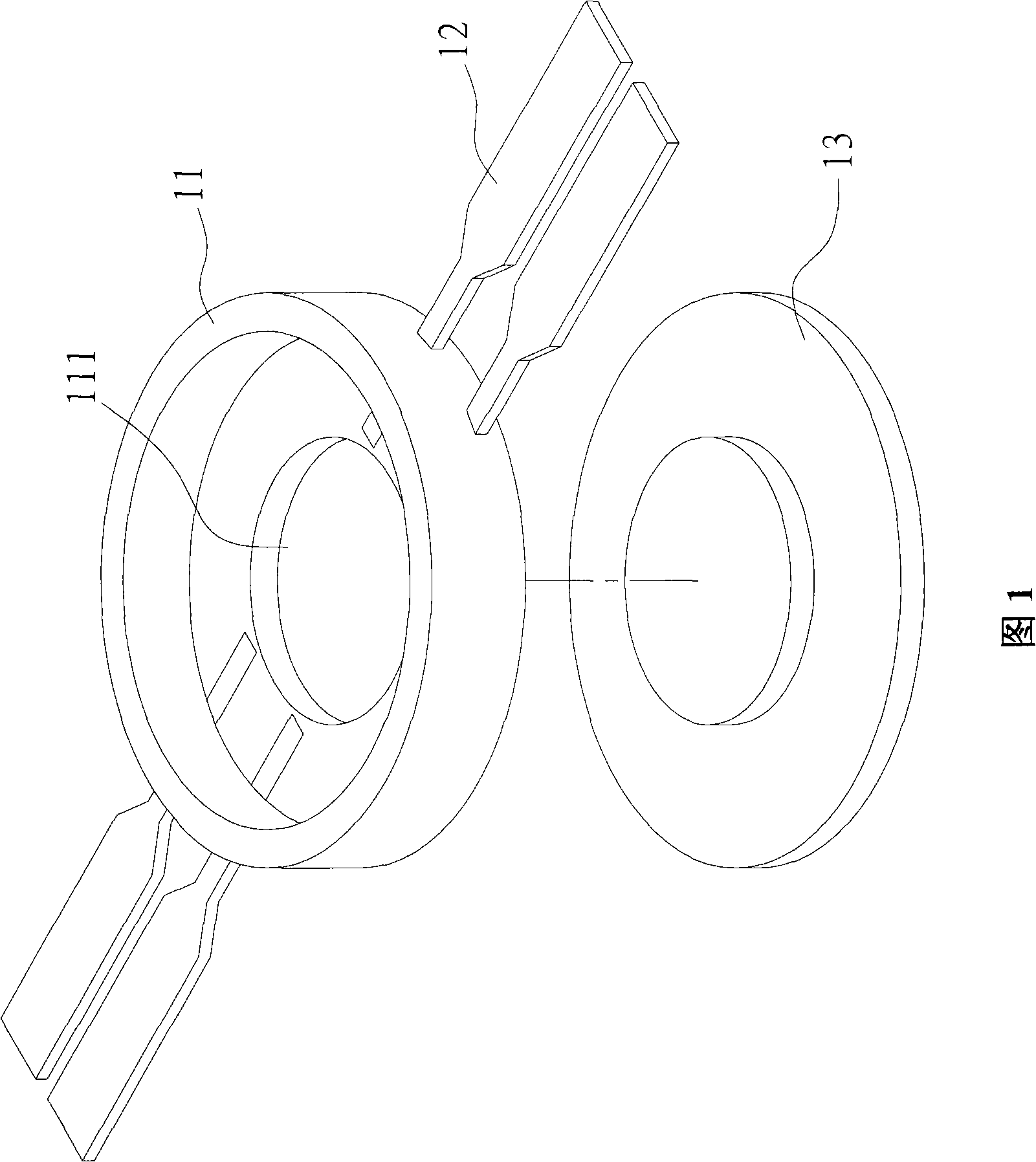

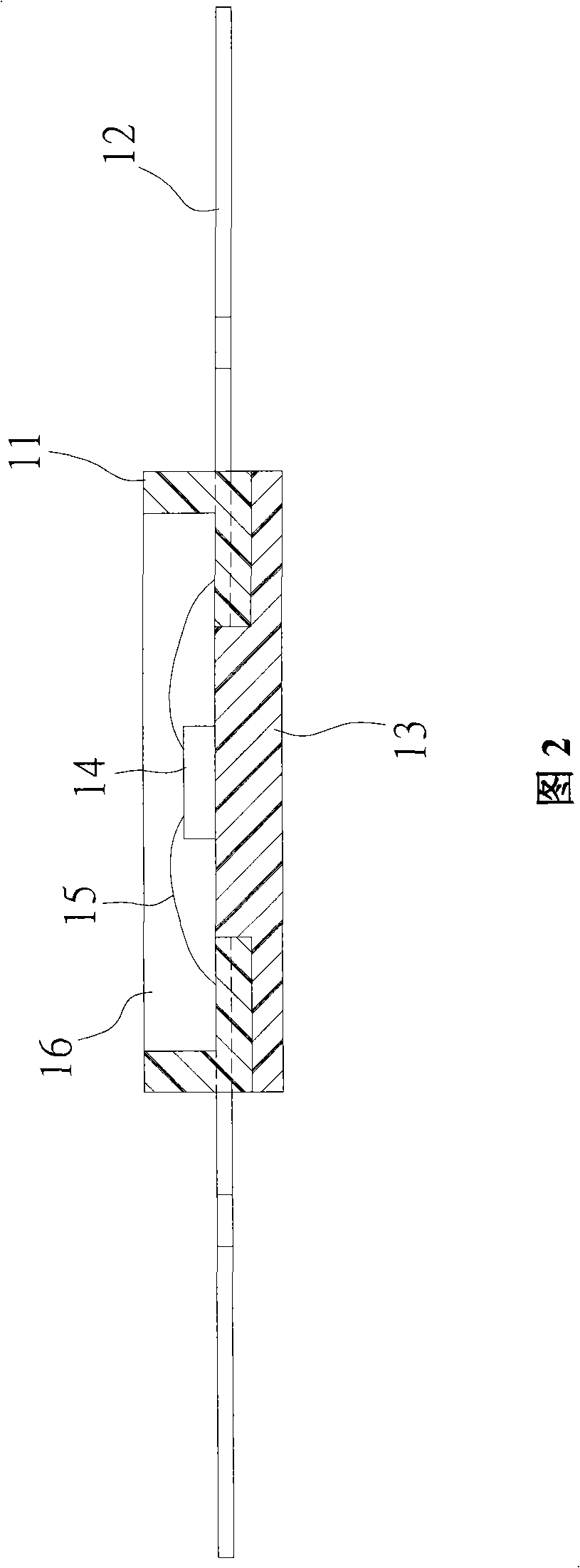

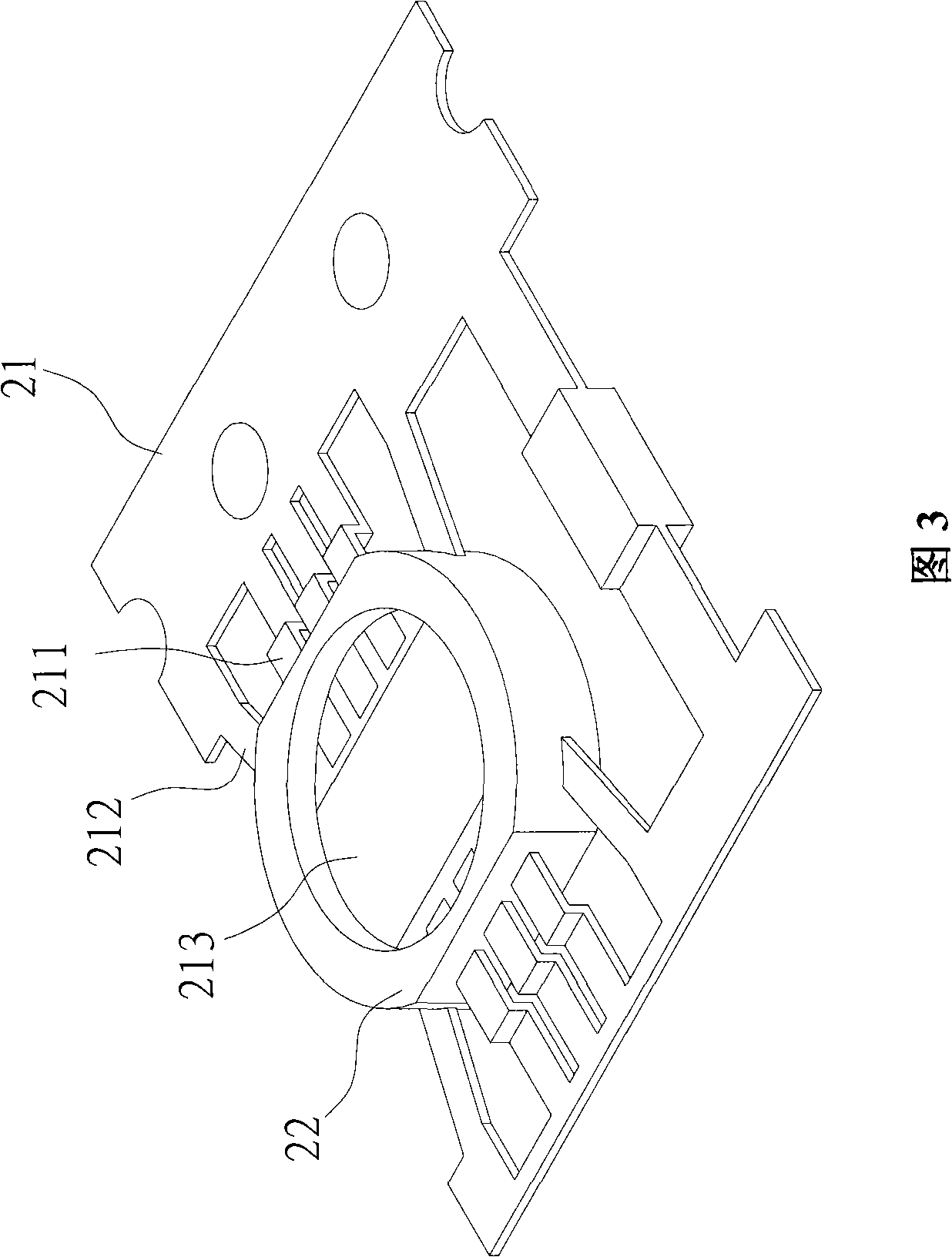

[0086] Please see first Figure 5 , Fig. 6A and Fig. 6B show the first embodiment of the manufacturing method and structure of the heat dissipation base of the surface-mounted diode bracket of the present invention, and the heat dissipation base 30 to be manufactured includes a first metal plate 31 and X second metal sheets, X is a natural number, the manufacturing method includes the following steps:

[0087] (a) provide a first metal substrate (not shown), which can be a continuous thin metal material, and stamp the first metal substrate so that the first metal substrate is stamped and formed with perforations 311 in advance; wherein, the number of perforations 311 There can be one or more according to actual design requirements.

[0088] (b) Provide a second metal substrate (not shown), which can be a continuous thin metal material, and stamp the second metal substrate so that the opposite sides of the second metal substrate are preformed with convex portions 321 and concav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com