High precision high flow rate micropore ceramic tube

A technology of microporous ceramic tube and large flow, which is applied in the direction of filtration and separation, gravity filter, chemical instruments and methods, etc., can solve the problems of large water filtration resistance, increase the flow of filtered water, reduce filtration resistance, and total resistance Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

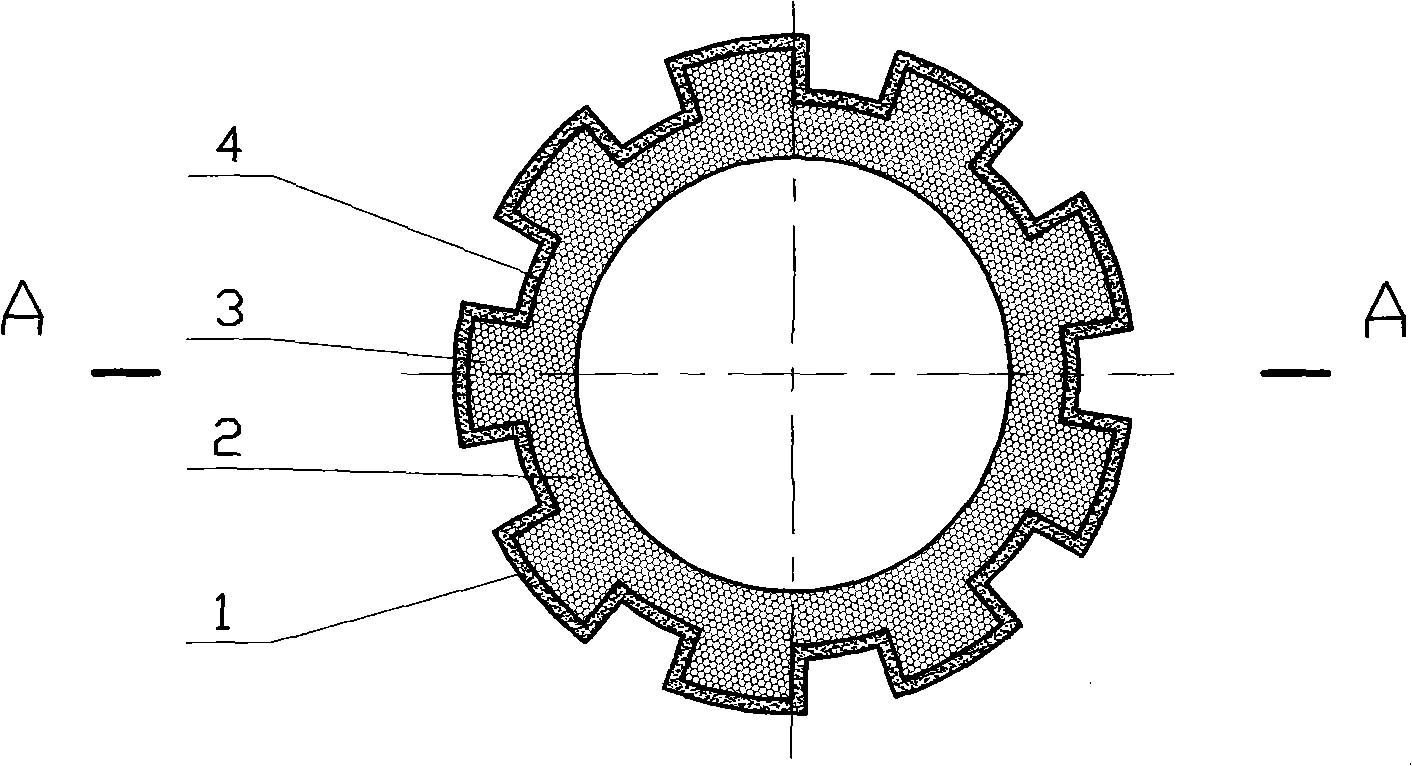

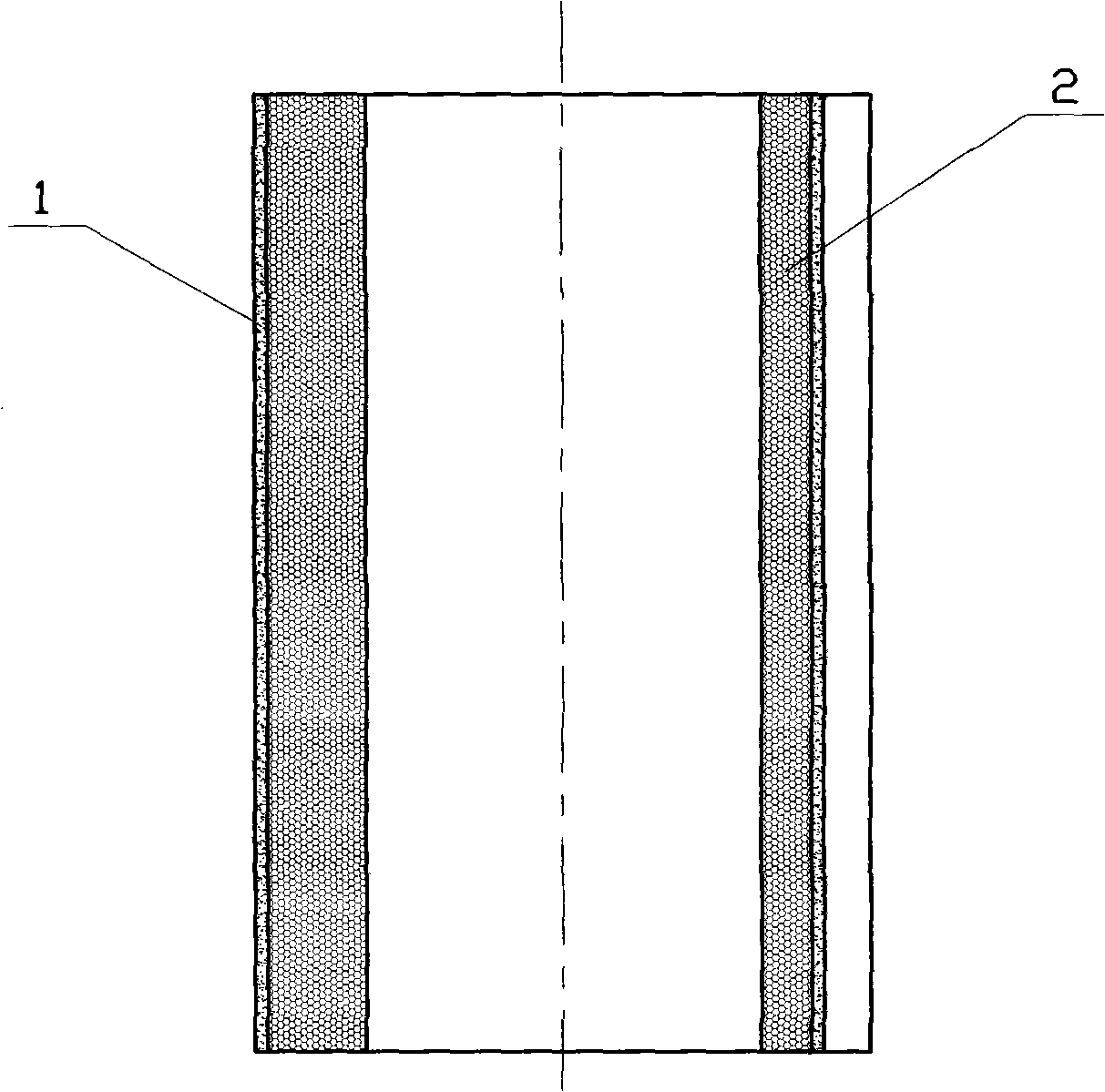

[0038] Example 1: Combination figure 1 with figure 2 As shown, the high-precision and large-flow microporous ceramic tube of this embodiment is made of two materials with obvious difference in filtration accuracy. The microporous ceramic tube (2) is made of a material with a very low filtration accuracy. Straight ribs (3) with parallel axes. The ribs (3) are made of the same material as the microporous ceramic tube (2). On all the water inlet surfaces of the microporous ceramic tube, that is, 3 of each rib (3) Each side surface and the bottom surface (4) of the groove between each convex rib (3) are provided with a filter layer (1) made of a material with higher filtering precision, and the thickness of the filter layer (1) is less than 2 mm.

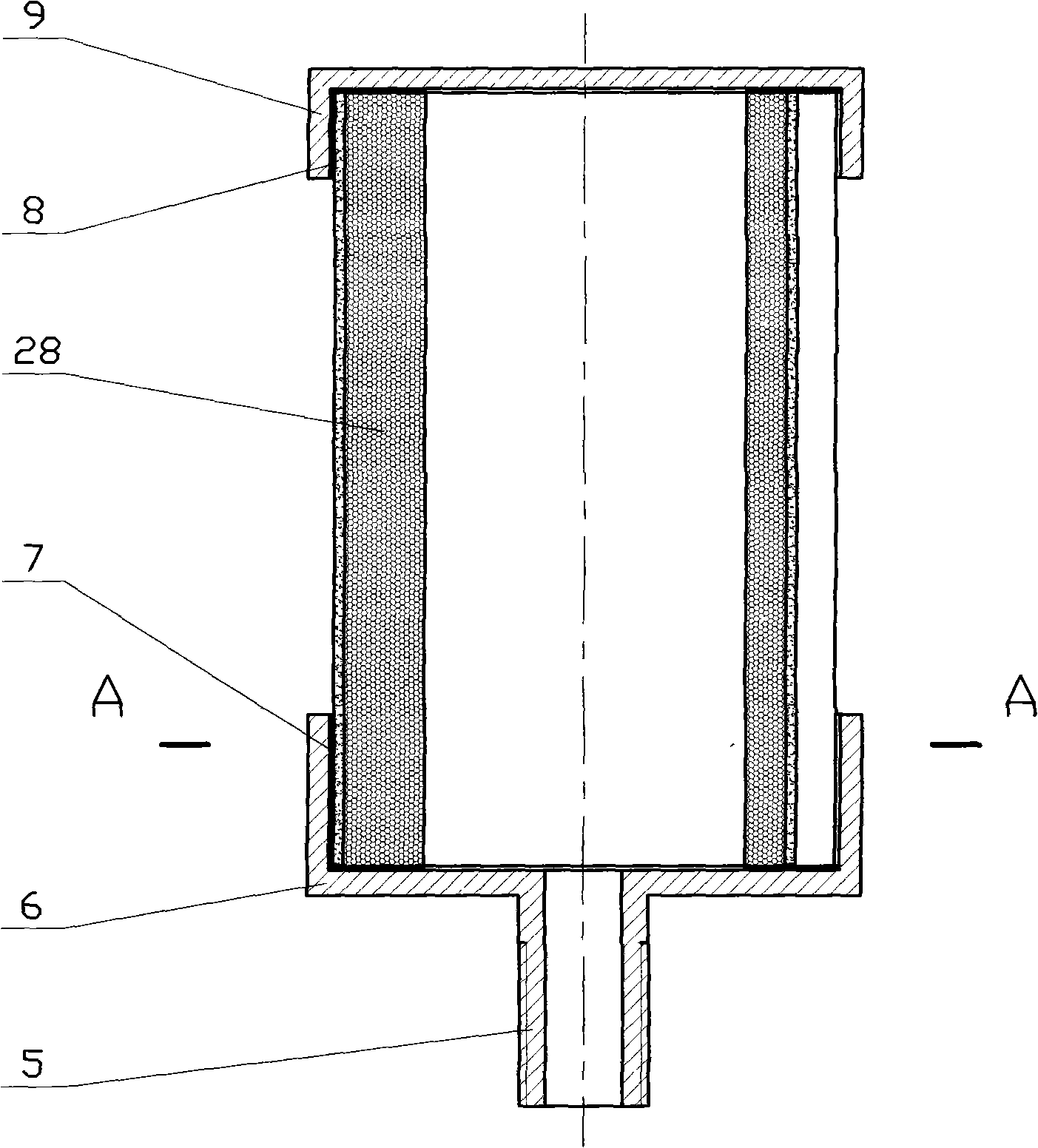

[0039] image 3 It is a schematic diagram of the structure of the microporous ceramic filter element of Example 1. Figure 4 Yes image 3 A-A section view. Combine image 3 with Figure 4 As shown, the upper end of the high-precision larg...

Embodiment 2

[0040] Embodiment 2: Combination Figure 5 with Figure 6 As shown, the high-precision and large-flow microporous ceramic tube of this embodiment is made of two materials with obvious difference in filtration accuracy. Its structure is a bottom (29) at one end and a large opening at the other end, which is arranged on the outer surface of the tube wall (11). The straight ribs (14) parallel to the tube axis, the tube wall (11), the bottom (29) and the ribs (14) are all made of materials with very low filtration precision. The three ribs (14) are The side surface, the bottom surface (13) of the groove between the ribs (14), the inner surface of the pipe wall (11), the end surface (30) of the large open end and the inner surface of the bottom (29) are all equipped with filtering precision The filter layer (12) made of higher material; the filter layer (12) plays a filtering role, and its thickness is less than 1 mm; a diversion channel (10) is provided in the tube wall (11) at the ro...

Embodiment 3

[0042] Embodiment 3: Combination Picture 9 As shown, the high-precision and large-flow microporous ceramic tube of this embodiment is made of two materials with obvious difference in filtration accuracy. There are many annular ribs (20) on the outer surface of the tube wall (22), and the tube wall (22) ) And ribs (20) are made of materials with very low filtration accuracy. The three side surfaces of each rib (20), the bottom surface (19) of the groove between each rib (20) and the pipe wall ( The outer surface of 22) is provided with a filter layer (21) made of a material with higher filtration precision. The filter layer (21) plays a filtering role and its thickness is less than 1 mm; the pipe wall (22) plays a role of diversion and structural strength Function, its thickness is about 6 mm.

[0043] Picture 10 It is a schematic diagram of the structure of the microporous ceramic filter element of the third embodiment. The upper end of the high-precision and large-flow micropo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com