Heat insulation decoration integrated plate and method of manufacture

A manufacturing method and integrated panel technology, which is applied in the decorative panel of buildings and its manufacturing field, can solve the problems of manufacturing process dependence, high cost of aluminum panels, and limited selection of thermal insulation materials, etc., and achieve the effect of low cost

Inactive Publication Date: 2008-10-22

浙江博星化工涂料有限公司

View PDF0 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Aluminum panels and aluminum-plastic panel curtain walls have always been the first choice for high-end decoration of building exterior walls, but the mandatory implementation of building energy-saving regulations requires building walls to be insulated and energy-saving. Curtain wall insulation is not only expensive, but also more complicated to install

One of the construction methods is to first conduct insulation construction and then paint or tile decoration outside the insulation layer, but these methods have several disadvantages: 1. The construction period is long, usually 3-8 months. 2. The construction quality depends on the weather. 3. 1. The selection of insulation materials is limited, or the construction cost is high and wasteful during on-site construction, or the energy saving efficiency is low, or the joints are easy to crack

At present, there are also prefabricated thermal insulation and decorative composite panels in the factory. When the thermal insulation layer and the decorative layer are combined, they are bonded by direct bonding.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

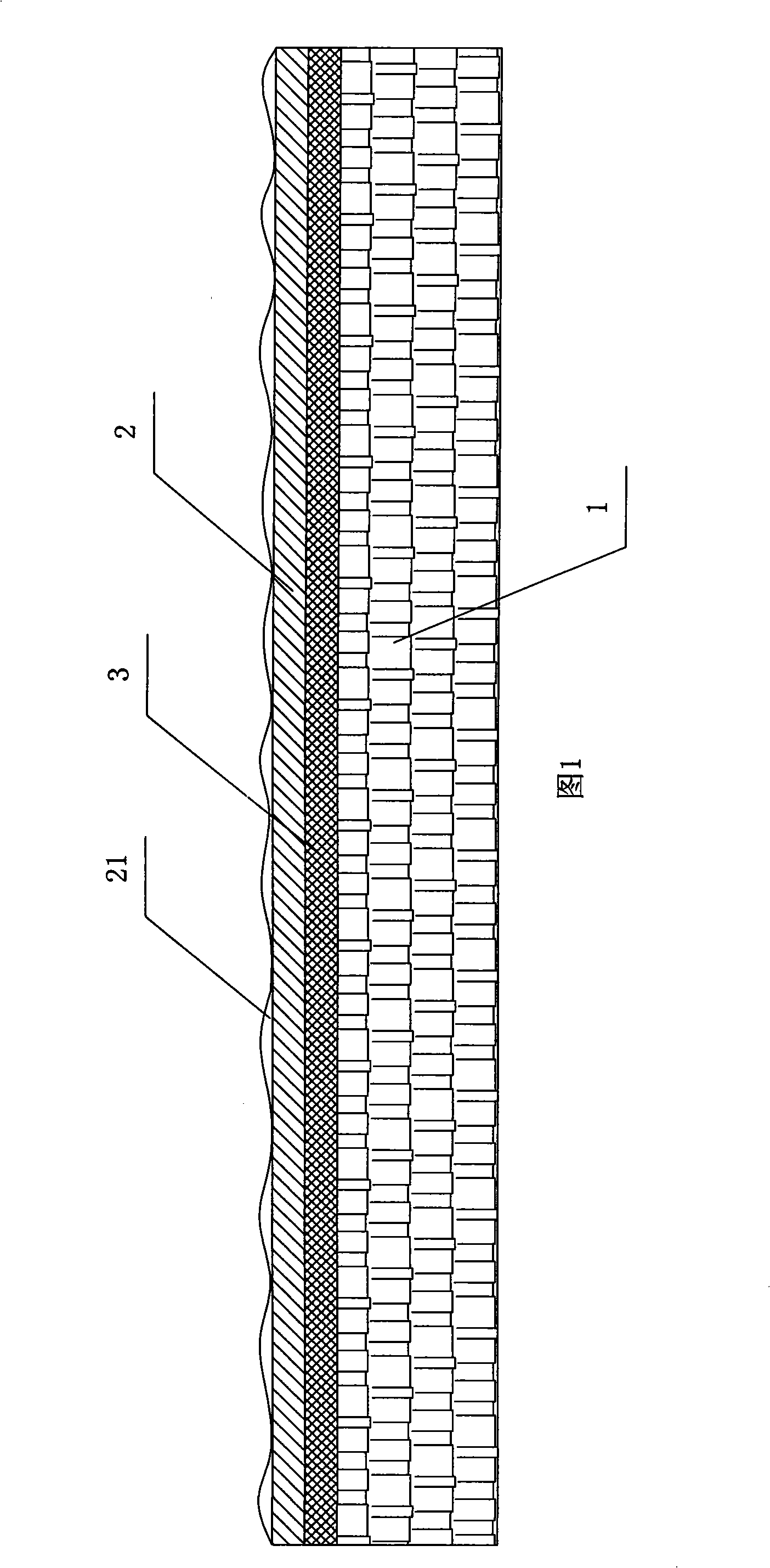

The invention provides a heat-preservation decorative integrated plate, which comprises a heat-preservation layer and a decorative face plate layer, wherein both layers are glued by a shaping bonding layer which takes a foaming elastic high molecular material as an adhesive carrier. The integrated plate has the characteristics of high gluing strength, good heat-preservation effect and low cost, and can be made into any shape according to the building feature of a client; therefore, the integrated plate reaches multiple functions of heat preservation, energy conservation and decoration, and is particularly suitable to be used as a top-grade, efficient and low-cost heat-preservation and decorative system of a building outer wall body. The invention also provides a method for making the integrated plate. The method comprises the following steps that: a porous type foaming elastic high molecular material layer is dipped in gluewater, and is extruded in advance to obtain a predetermined glue content; the upper surface and the lower surface of the high molecular material layer, respectively glued to the heat-preservation layer and the baseplate of the decorative face plate layer, are extruded to a predetermined thickness and then are dried. The method can make the heat-preservation decorative integrated plate of high quality at low cost.

Description

Insulation and decoration integrated board and its manufacturing method technical field The invention relates to the technical field of building decorative panels and manufacturing methods thereof. Background technique Traditionally, there are two types of exterior wall decoration: paint and facing bricks. In addition, there are high-grade aluminum panels, aluminum-plastic panels, stone and glass curtain walls. Since the country has mandated building energy conservation, exterior wall insulation has become one of the most popular research fields for building materials. . Aluminum panels and aluminum-plastic panel curtain walls have always been the first choice for high-end decoration of building exterior walls. However, the mandatory implementation of building energy-saving regulations requires building walls to be insulated and energy-saving. Curtain wall insulation is not only expensive, but also more complicated to install. One of the construction methods is to first ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E04F13/07B32B5/18B32B7/12B32B37/12

Inventor 王君瑞

Owner 浙江博星化工涂料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com