Sealing method of battery vacuum and evacuating device

A technology of vacuum sealing and vacuuming device, applied in battery pack parts, circuits, electrical components, etc., can solve problems such as affecting battery life, affecting battery performance, increasing battery thickness, etc., to ensure performance, easy Control, reduce the effect of thickness

Active Publication Date: 2010-08-25

BYD CO LTD

View PDF1 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

1. The presence of gas in the battery will increase the thickness of the battery and reduce the yield

2. There is a lot of gas in the battery, and more electrolyte will be discharged when sealing, resulting in a decrease in the amount of residual electrolyte in the battery, which will eventually affect the service life of the battery

3. The gas generated will affect the performance of the battery

However, since it is described as evacuating in a vacuum chamber, there is a problem that when evacuating in such a large vacuum environment, the gas will be drawn out, but at the same time the electrolyte in it will also be drawn out

To ensure the capacity of the battery, it is necessary to refill the electrolyte again, which is equivalent to increasing the process or increasing the cost and labor.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Login to View More

Abstract

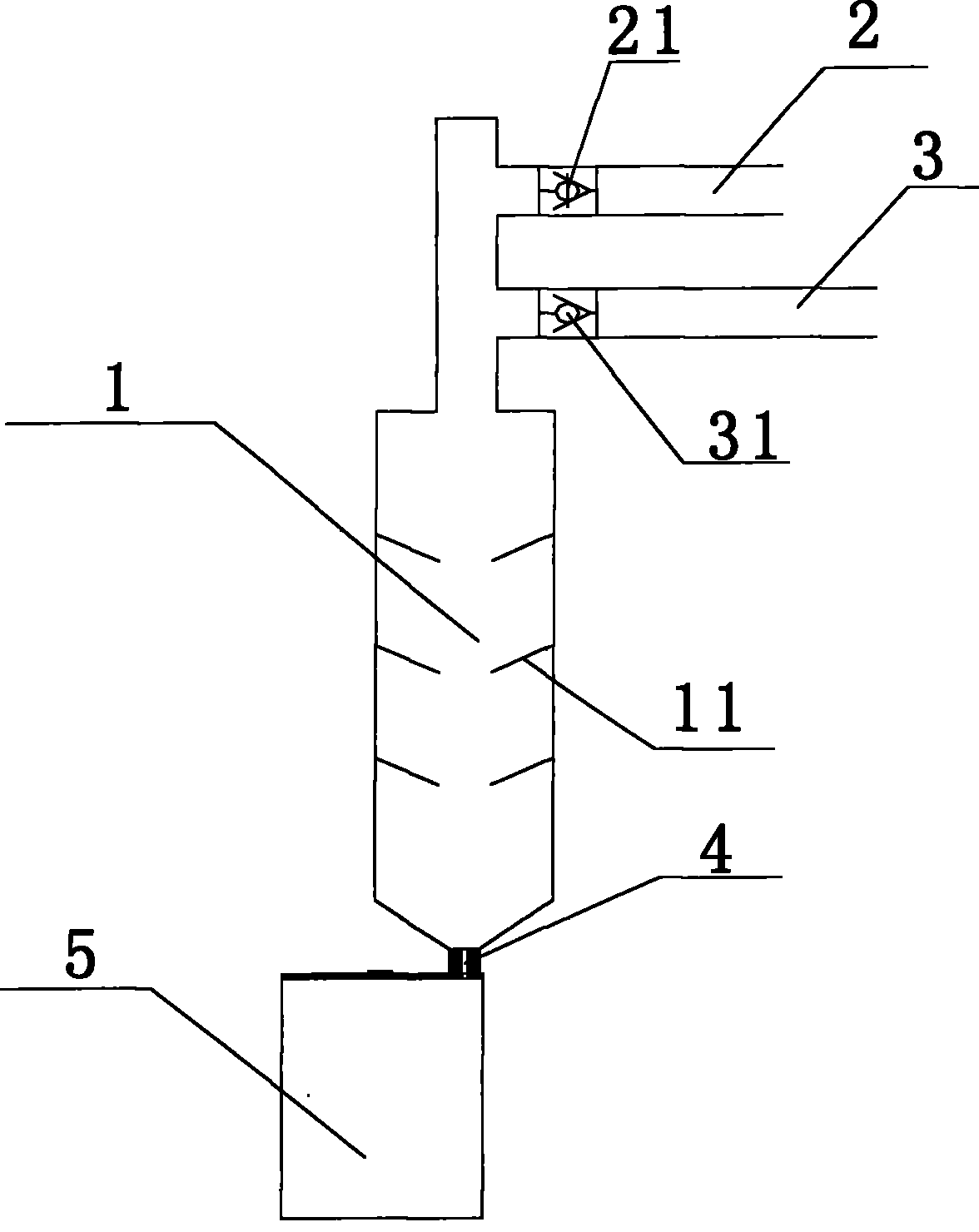

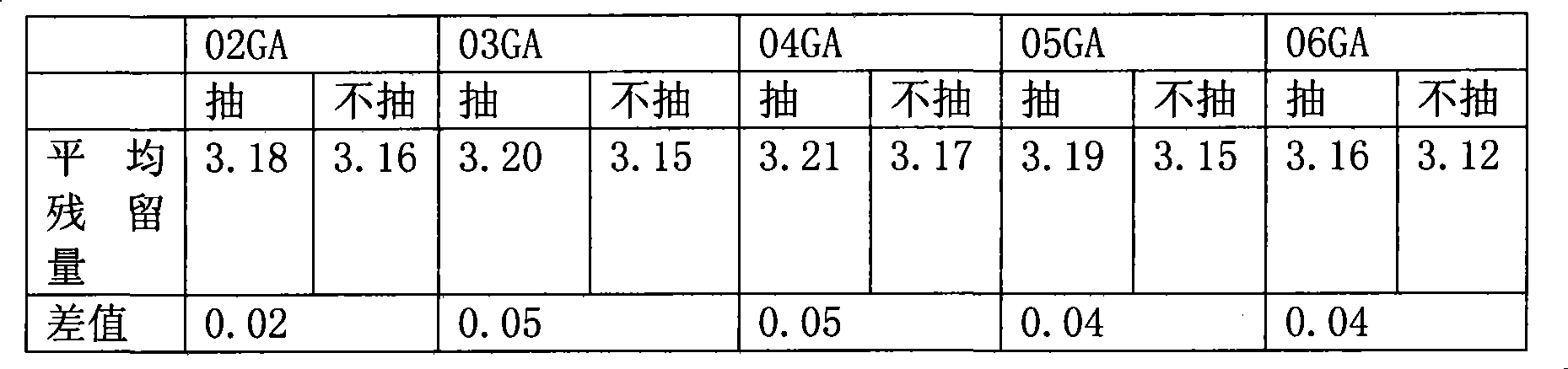

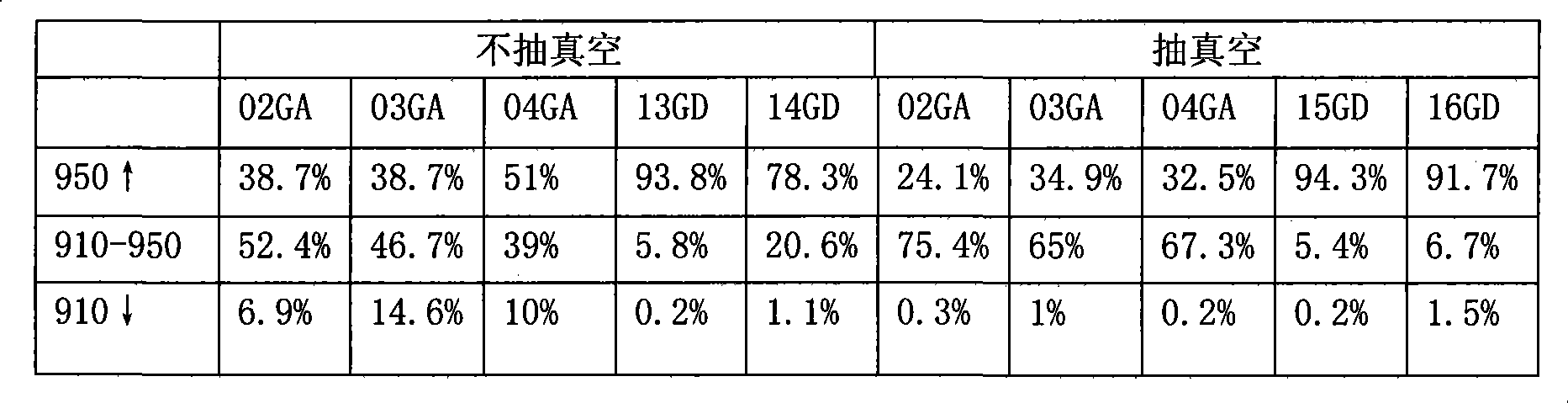

The invention discloses a battery vacuuming and sealing method and a vacuum extractor, relating to the battery production process field. The invention discloses a vacuum extractor which comprises a vacuum tube, a drying tube, an intermediate vessel capable of separating gas from liquid, and a needle. The method is as follows: the vacuum extractor is aimed at a liquid injection hole for vacuum extraction; gas, water and electrolyte are extracted into the intermediate vessel; the gas and the water are extracted from the vacuum tube with the electrolyte left in the intermediate vessel; dry air is blown from the drying pipe to get the electrolyte back to a battery; and finally the battery is sealed. The invention guarantees the electrolyte does not leak during the vacuum extraction. The vacuum extraction sealing method and the vacuum extractor of the invention can effectively get rid of harmful gases while guaranteeing the electrolyte in the battery is not extracted out or does not leak so as to influence the volume of electrolyte in the battery during the vacuum extraction, and, to some extent, reduce the thickness of the battery and guarantee the performance of the battery.

Description

【Technical field】 The invention relates to the field of battery production technology. 【Background technique】 At present, in the battery production process, the problem of sealing after formation or sealing before formation is involved. During the formation, some gases, such as HF, CO, CO2, NO, etc., will be generated, which will cause the battery to bulge, and at the same time, it will be difficult to seal, which seriously affects the performance and yield of the battery. The residual gas in the battery will cause the following effects: 1. The existence of gas in the battery will increase the thickness of the battery and reduce the yield. 2. There is a lot of gas in the battery, and more electrolyte will be discharged when sealing, resulting in a decrease in the amount of residual electrolyte in the battery, which will eventually affect the service life of the battery. 3. The gas generated will affect the performance of the battery. In the comparative document CN200...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01M2/00H01M2/36H01M2/02H01M50/10H01M50/183H01M50/609

CPCY02E60/10

Inventor 彭高平刘卫平

Owner BYD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com