Automatic rapid plug-in mechanism

A plug-in mechanism and automatic technology, which is applied in the direction of connection, structural parts, clamping/spring connection, etc., can solve the problems of expanding the mileage, not waterproof, and power loss, etc., to achieve extended mileage, convenient maintenance, Power Saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

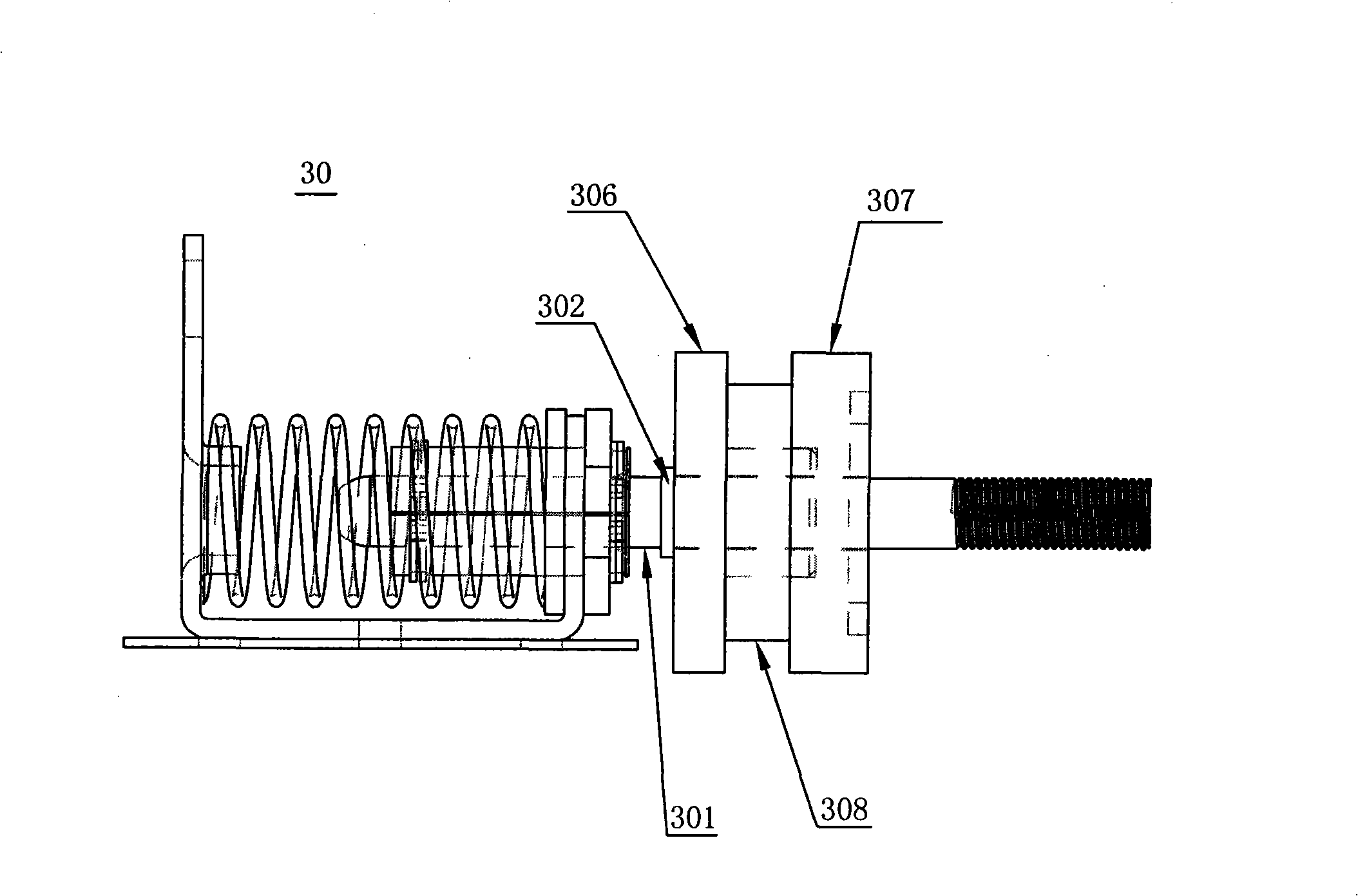

[0027] The automatic quick plug-in mechanism of the present invention will be described in detail below with reference to the accompanying drawings.

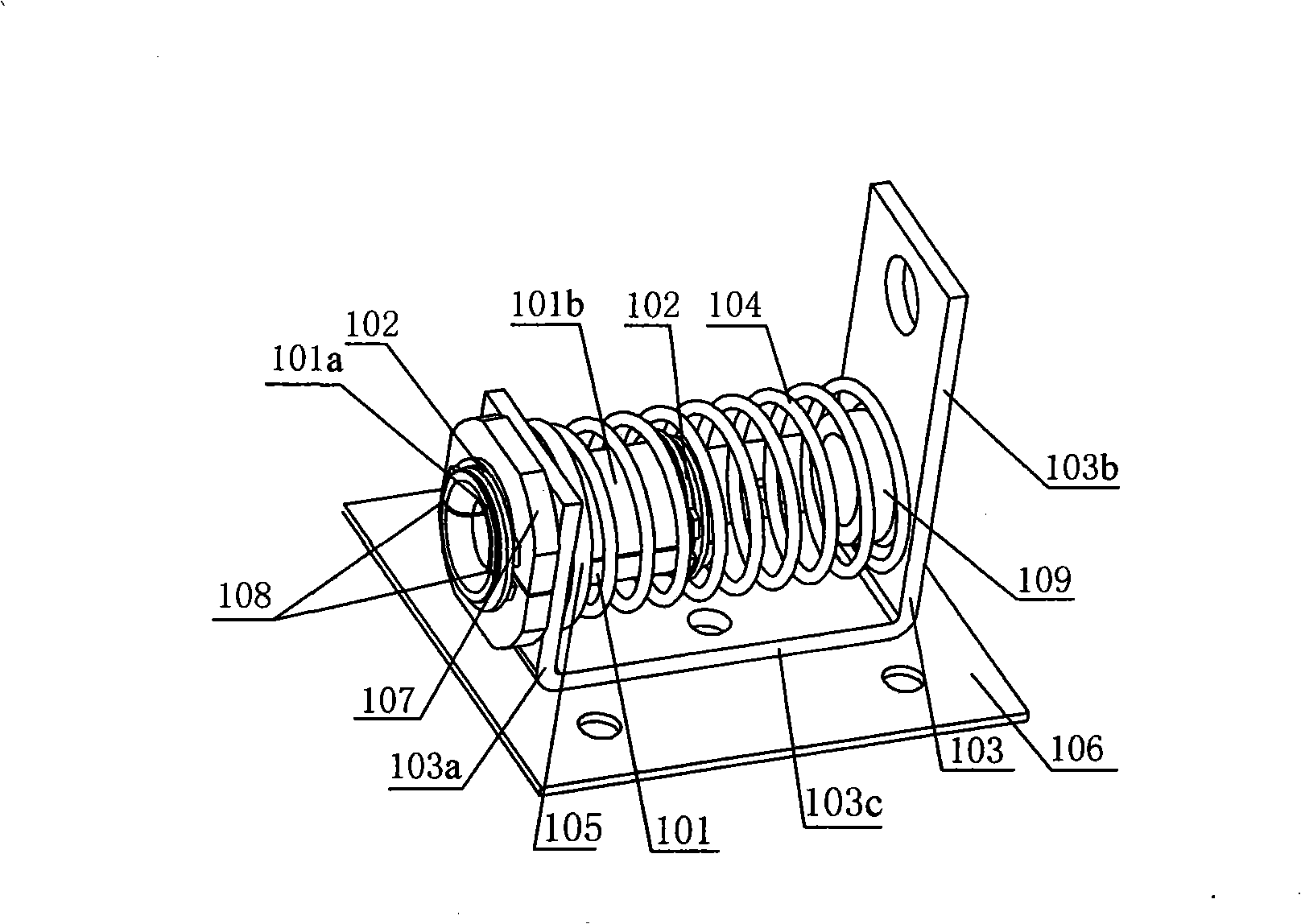

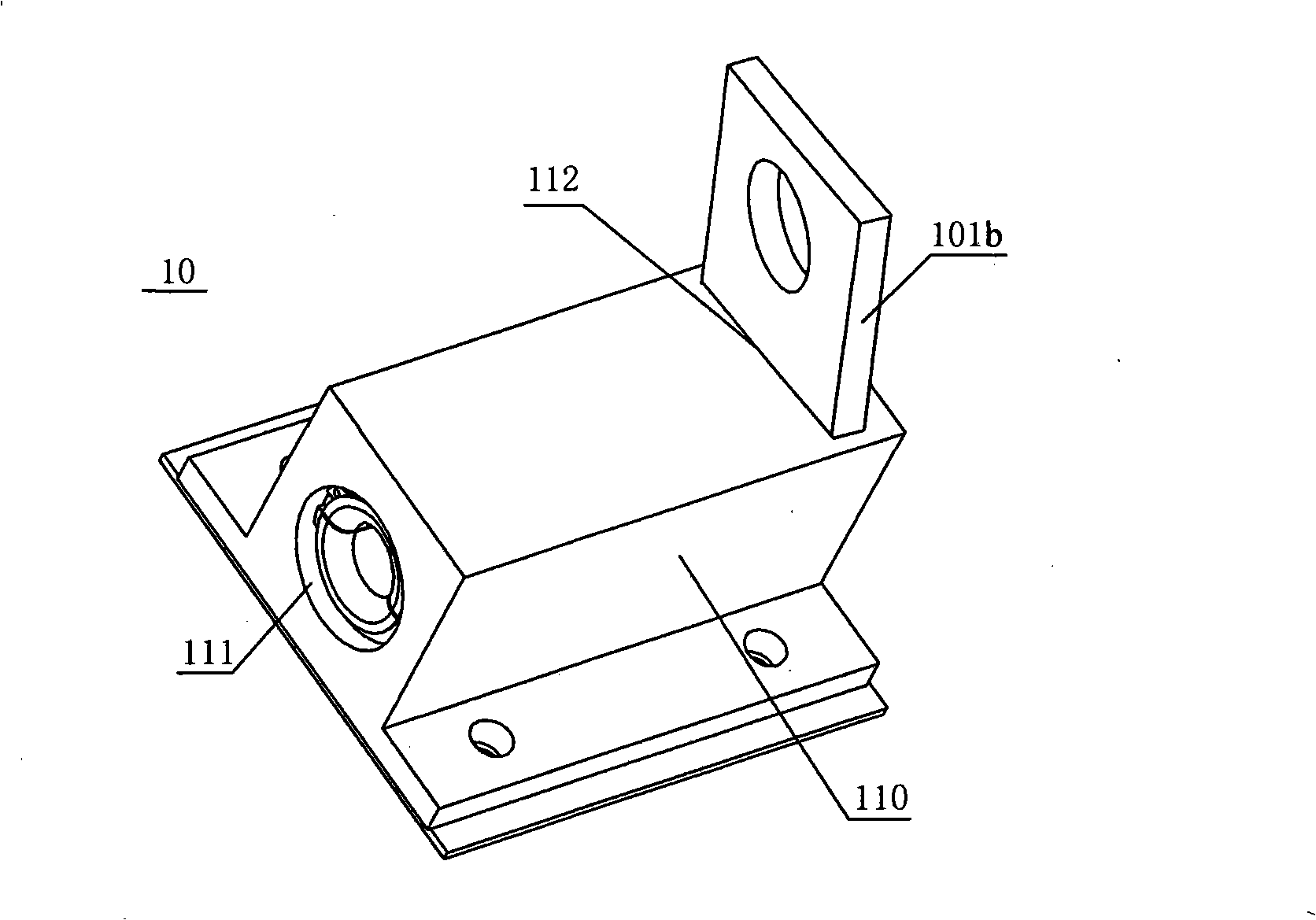

[0028] figure 1 Shows the jack assembly 10 of the automatic quick-connect mechanism 1 according to the first embodiment of the present invention. Wherein, the jack assembly 10 has certain expansion and retraction capabilities. Such as figure 1 As shown, the socket assembly 10 includes a socket body 101, which is a hollow cylinder, and a cutout 108 is formed on the wall of the cylinder along its central axis. And a hoop spring 102 is respectively fixed at both ends of the jack body 101 . Preferably, the inner diameter of the hoop spring 102 is equal to or slightly larger than the outer diameter of the socket body 101 . In this way, when the plug body 301 whose end surface diameter is larger than the inner diameter of the outer port of the jack body 101 is inserted into the jack body 101, the jack body 101 can expand, and unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com