Impulse magnetic valve for removing dust and clearing ash

A technology of pulse solenoid valve and solenoid control valve, applied in valve details, valve device, valve operation/release device, etc., can solve the problems of failure, large energy loss, high processing cost, reduce manufacturing cost and save compressed gas , the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] This embodiment is used to explain the claims of the present invention, and the protection scope of the present invention is not limited to the following structures.

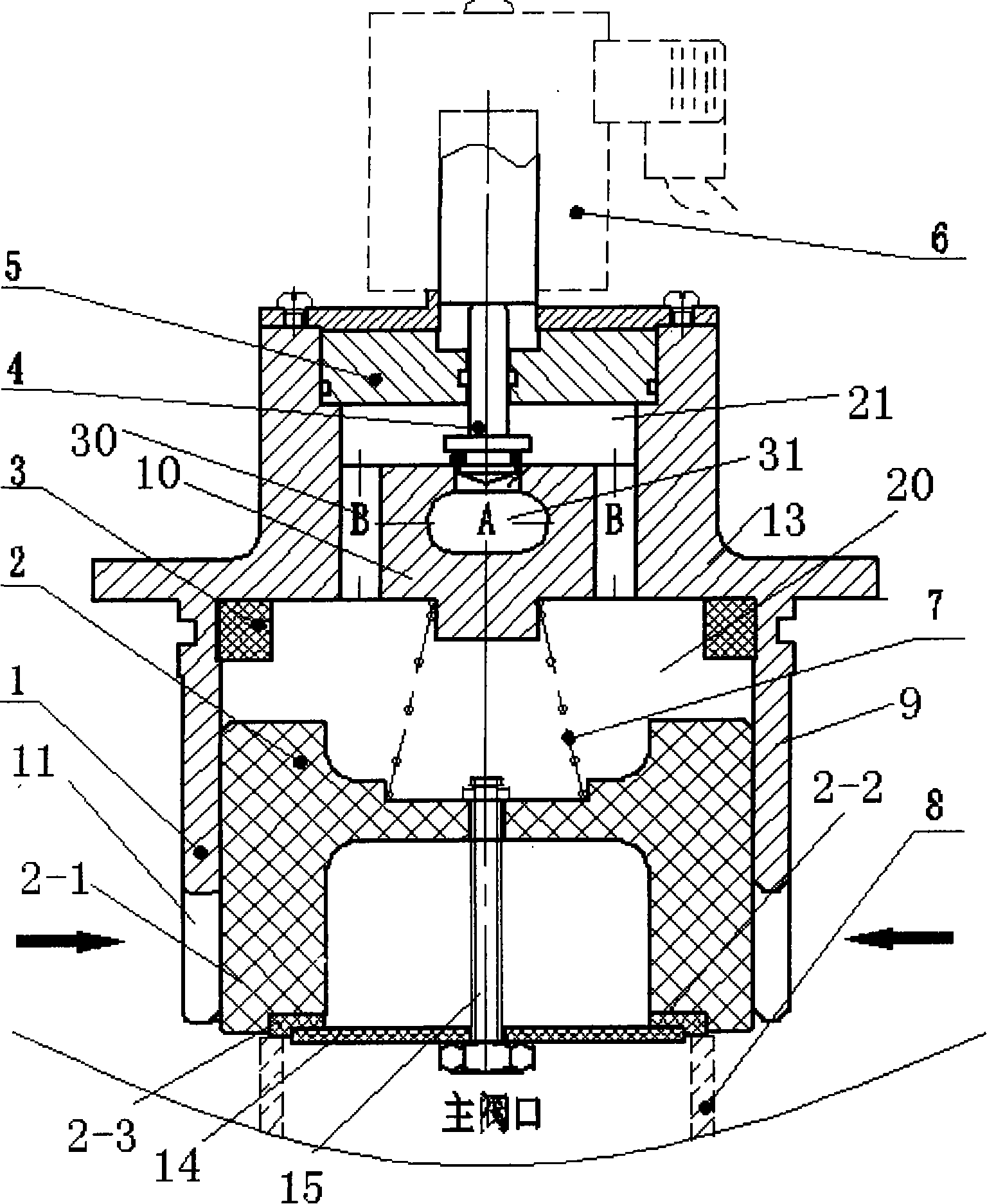

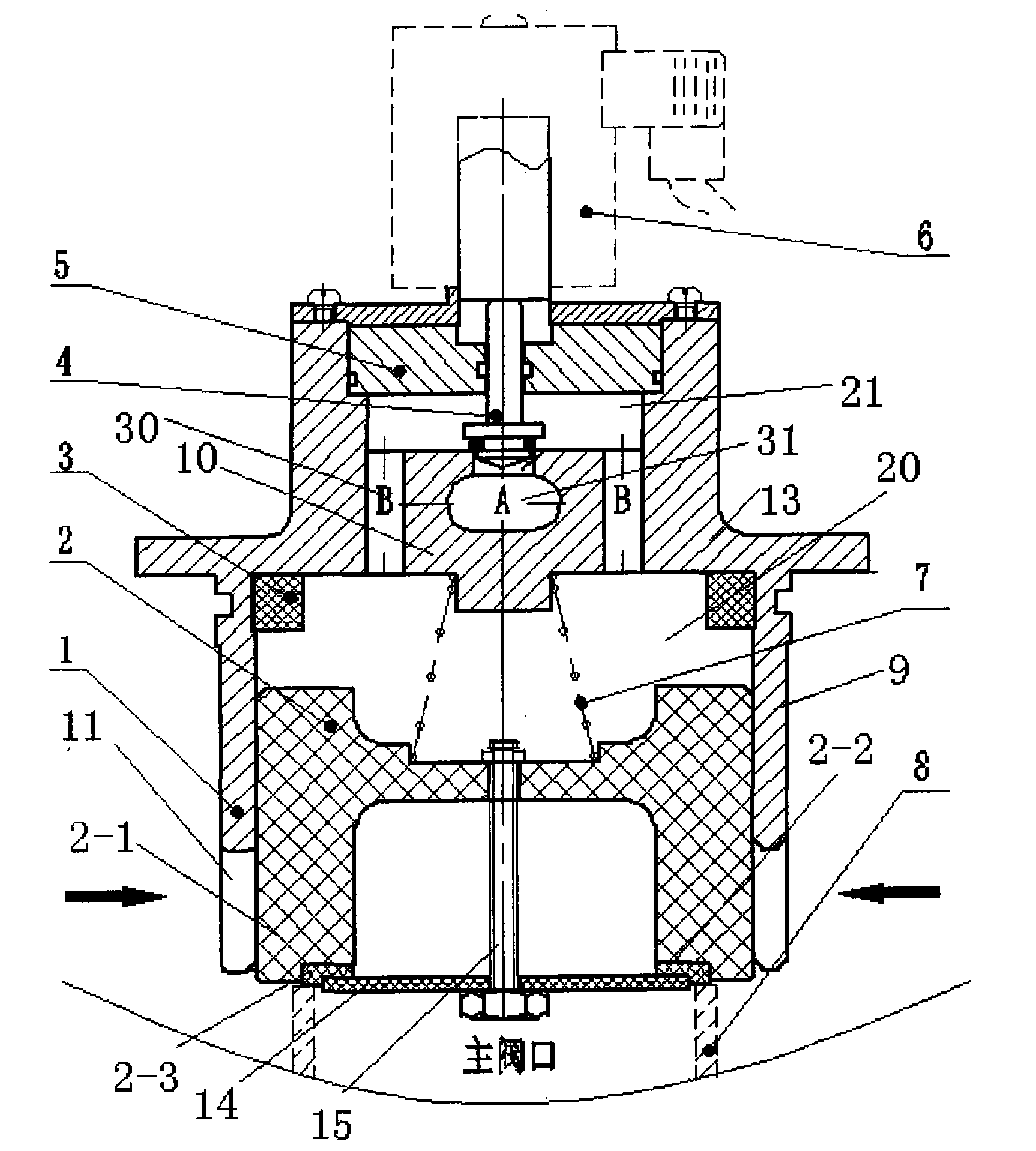

[0018] like figure 1 As shown, the valve body 1 has an upper and lower two-layer structure, forming two upper and lower cavities, that is, two upper and lower cavities; the lower cavity 20 is composed of a lower valve body wall 9 and a partition 10, and the valve body wall 9 is provided with a blowing groove 11 , The blowing grooves 11 are evenly opened along the circumference, and the number of spraying grooves 11 is set according to specific requirements.

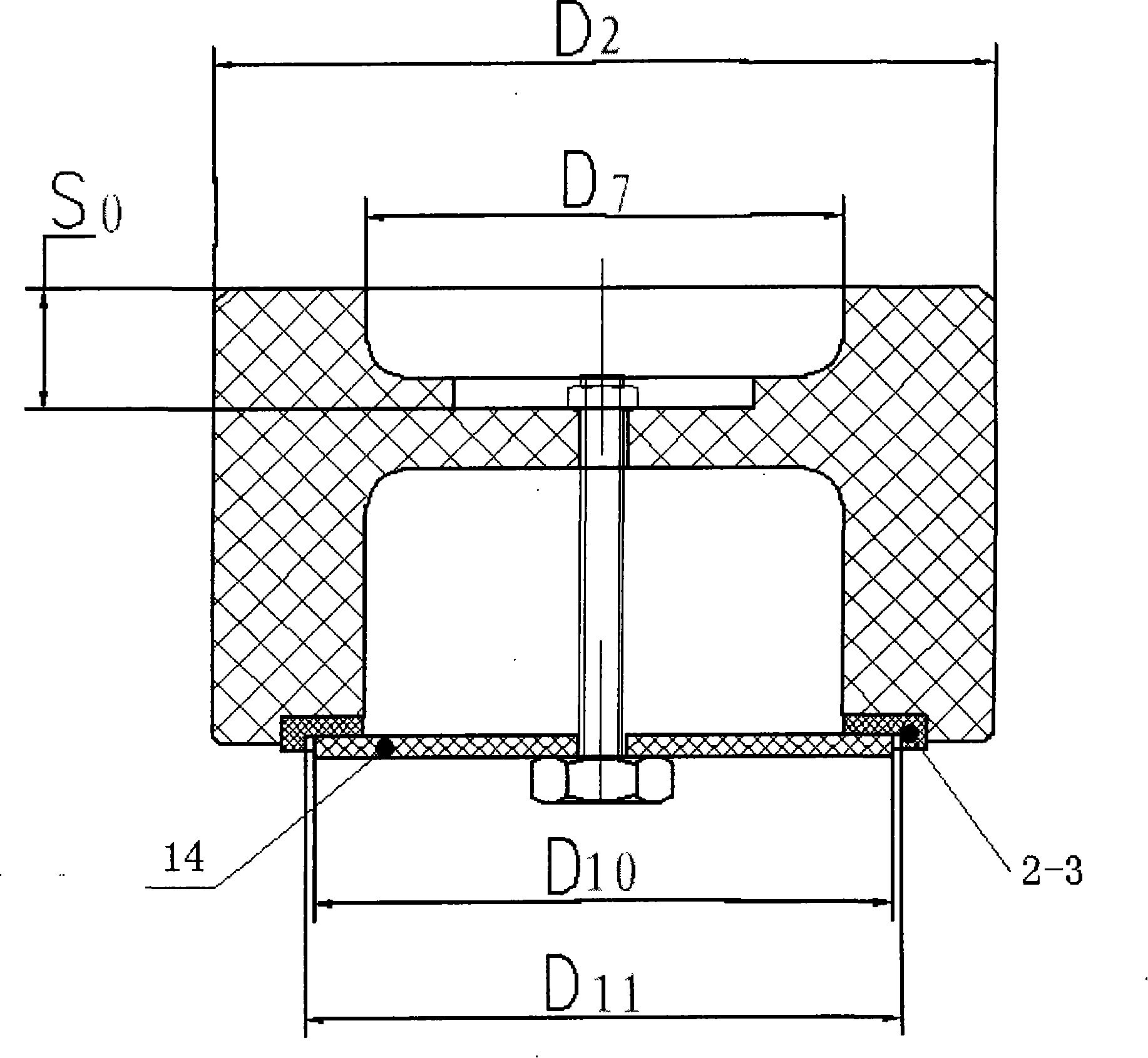

[0019] The lower cavity 20 is provided with a piston assembly 2, the piston assembly 2 includes a piston 2-1, a seal groove 2-2 is arranged at the opening of the piston 2-1, and a soft seal 2-3 is arranged in the seal groove 2-2, A pressing plate 14 connected with the piston, the pressing plate 14 is connected with the piston through a bolt 15, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com