Optical glass

A technology of optical glass and weight percentage, which is applied in the field of optical glass with better low-temperature moldability, and can solve the problems of reducing production costs, high energy consumption, and disadvantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

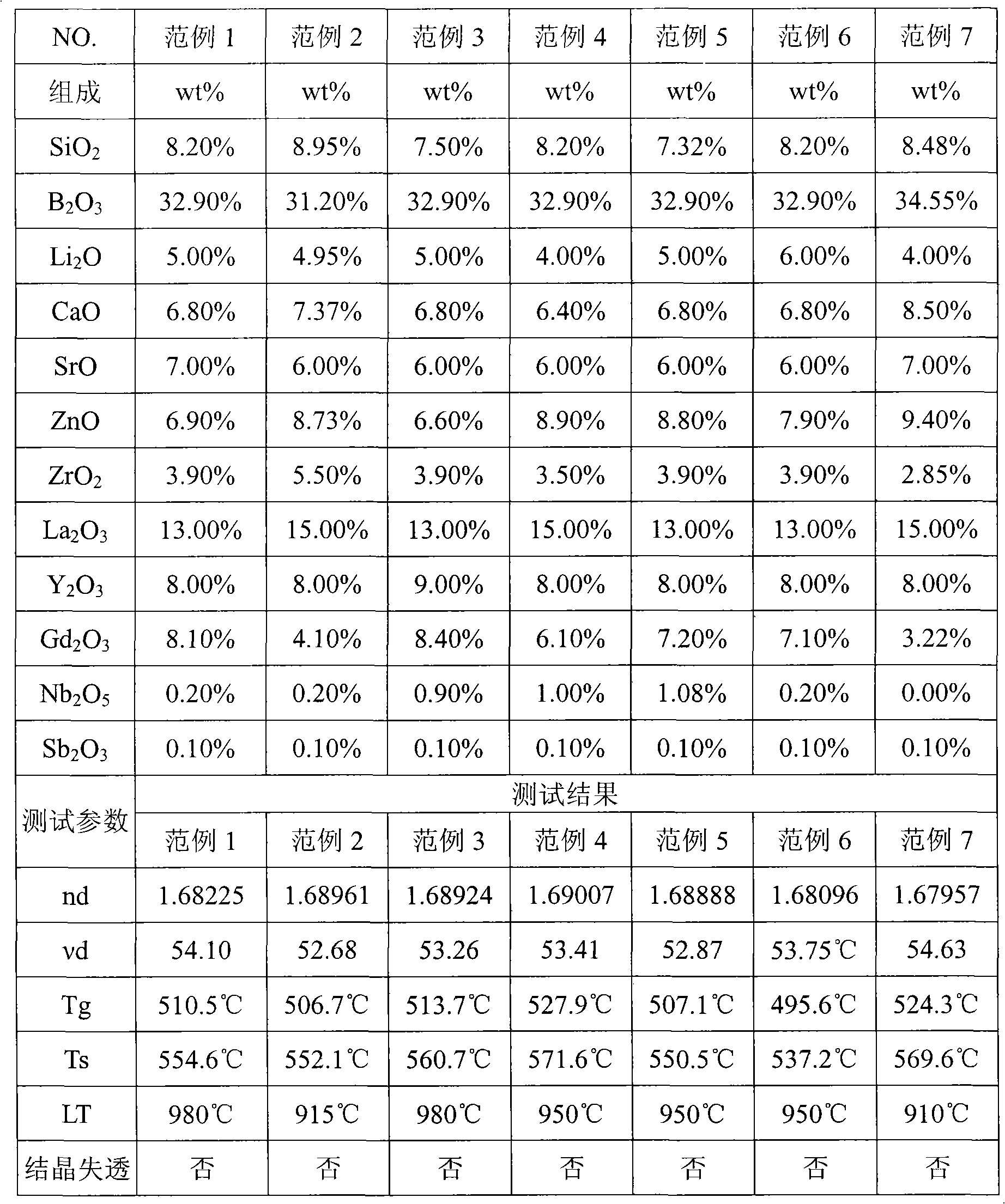

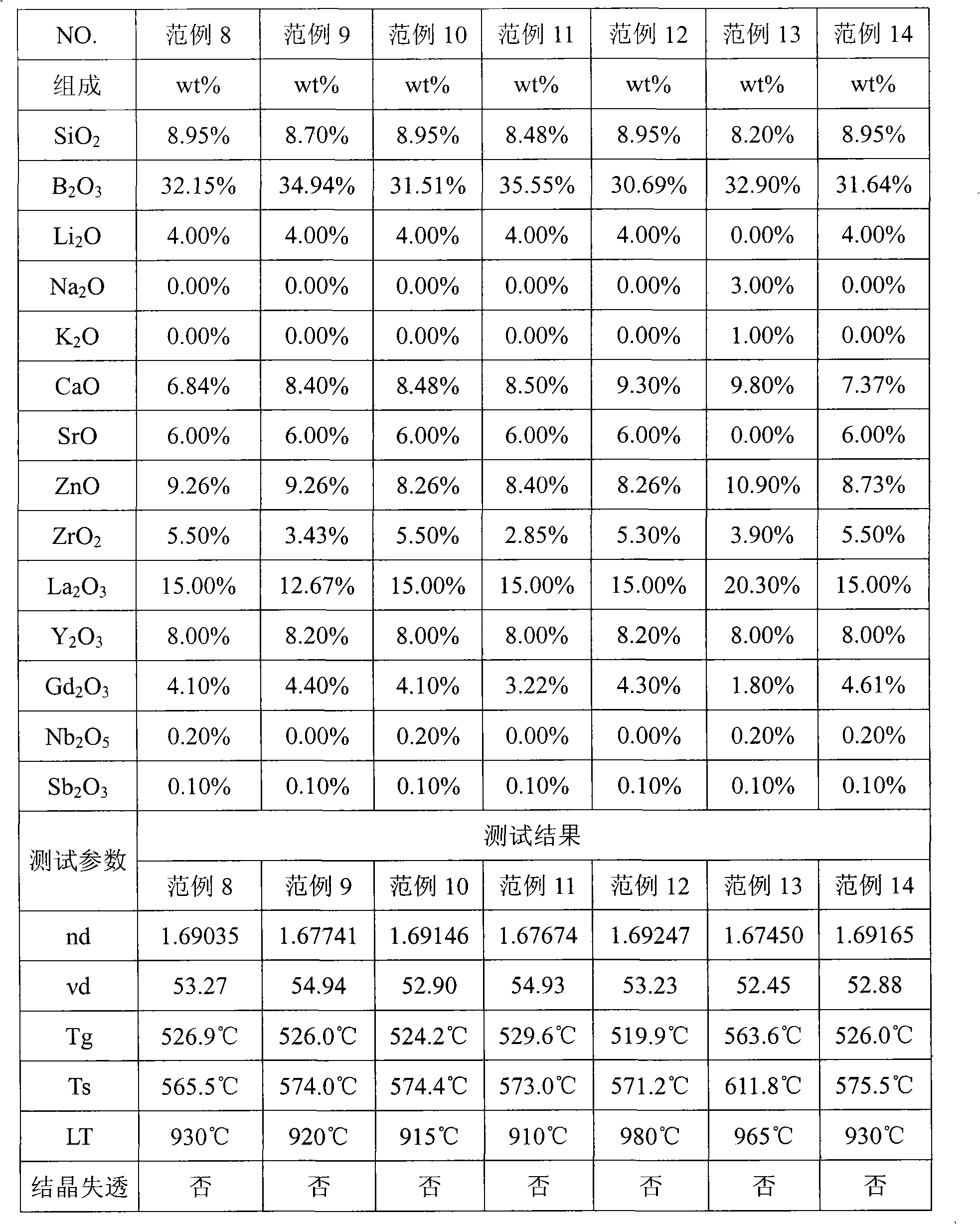

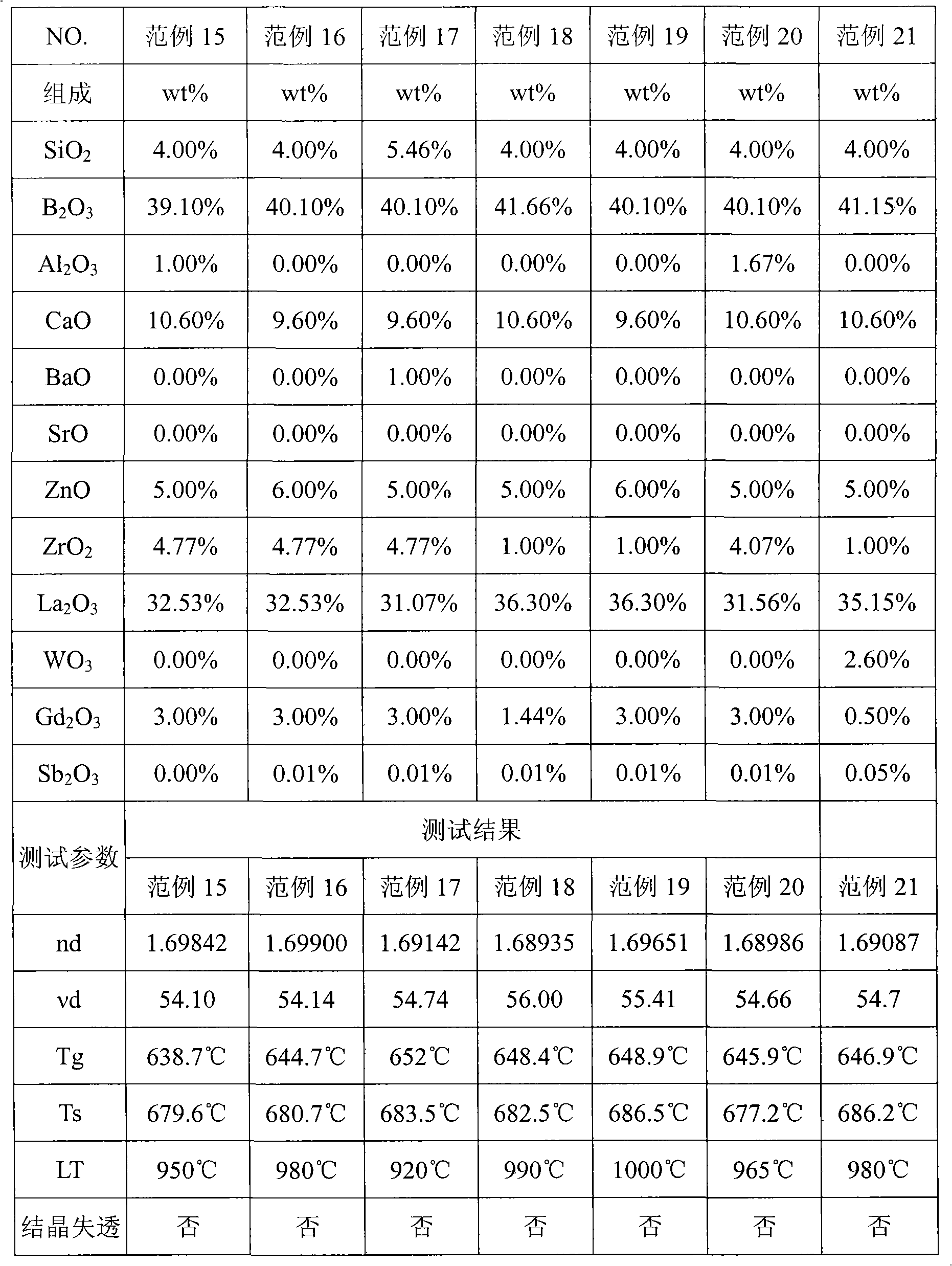

[0013] The optical glass provided by the invention, its basic composition contains SiO with a weight percentage of 2-11% 2 , 28-45% B 2 o 3 , 2~15% CaO, 3~18% ZnO, 1~8% ZrO 2 , 9-40% La 2 o 3 , 0.5-11% Gd 2 o 3 , 0~10% of Y 2 o 3 , 0~3% Al 2 o 3 , the sum of which does not exceed 8% of R 2 O (R is at least one of Li, Na or K), 0-5% of R'O (R' is at least one of Mg, Sr or Ba), 0-3% of WO 3 , 0~2% Nb 2 o 5 and 0~1% Sb 2 o 3 ; where SiO 2 , B 2 o 3 , CaO, ZnO, ZrO 2 , La 2 o 3 、Gd 2 o 3 It is an essential component of the optical glass of the present invention.

[0014] When the yield point temperature of the glass is required to be lower than 590°C, the optical glass of the present invention may have the following composition (expressed in weight percent): 6-11% SiO 2 , 28-40% B 2 o 3 , 2-12% CaO, 5-18% ZnO, 1-8% ZrO 2 , 9-30% La 2 o 3 , 1 to 11% Gd 2 o 3 , 1~10% of Y 2 o 3 , 1~7% Li 2 O, the sum of which does not exceed 8% of R 2 O (R is at le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| liquidus temperature | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com