Sliding window

A sliding window and window sash technology, applied in the sliding window field, can solve the problems of glass breakage, air infiltration, water tightness failure, etc., and achieve the effect of good water tightness and air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

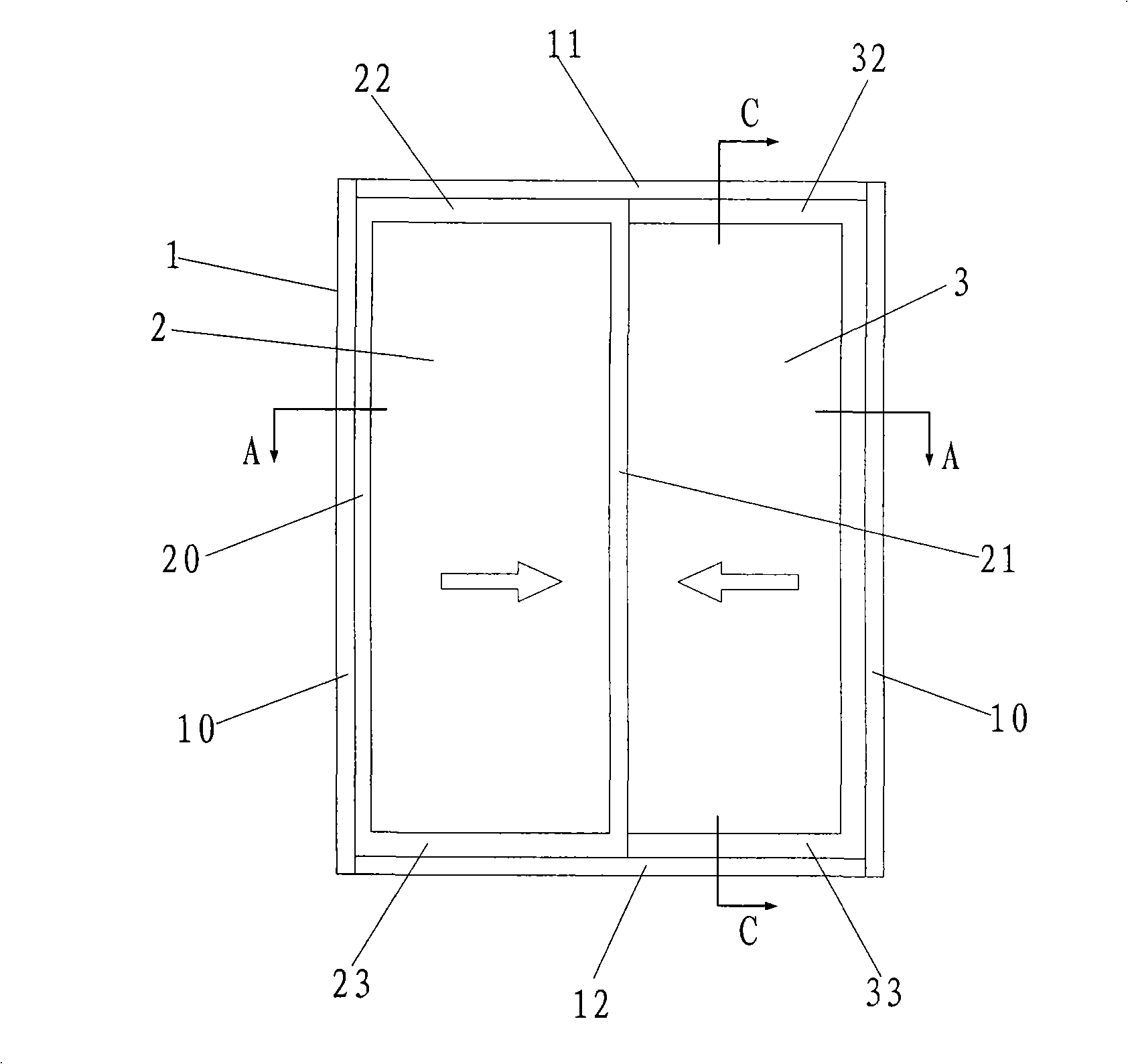

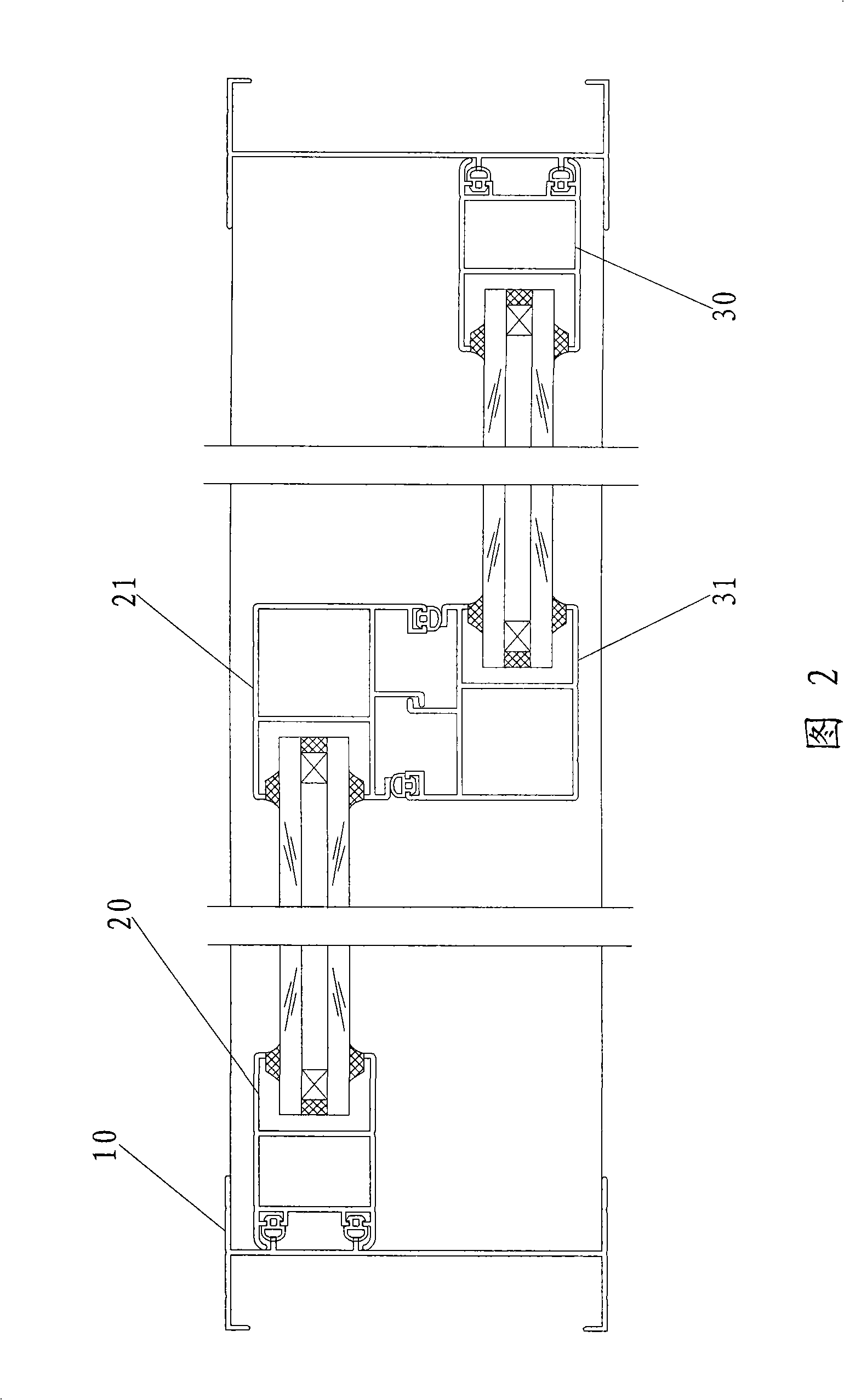

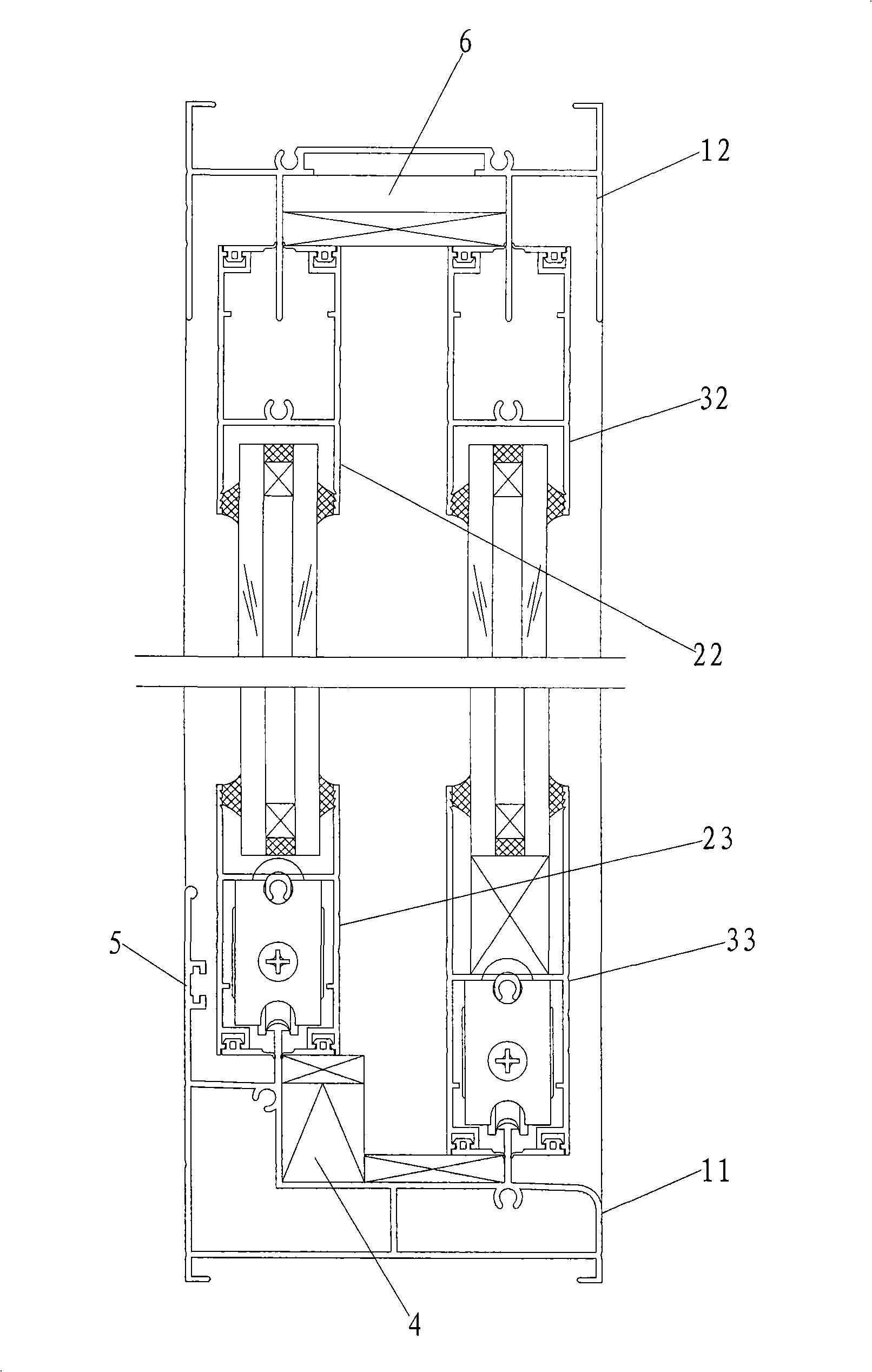

[0027] see Figure 1 to Figure 3 One embodiment of the sliding window designed by the present invention includes an outer frame 1 made of frame profiles, an inner sash 2 and an outer sash 3 slidably installed in the outer frame 1 .

[0028] The outer frame 1 is composed of a left and right frame 10, an upper frame 11 and a lower frame 12 with screw holes. The upper frame 11 and the lower frame 12 are connected to the frame 10 by screws, and a rubber sheet is used at the connecting end to prevent structural damage. Seepage. Both the upper frame 11 and the lower frame 12 are provided with an inner slideway and an outer slideway, and there is a height difference of 20 mm between the inner and outer slideways of the lower frame 12 .

[0029] The inner sash 2 is composed of interconnected side stiles 20, hooked side stiles 21, upper stiles 22, and lower stiles 23; the structure of the outer sash 3 is basically the same as that of the inner sash 2, and it also includes interconnect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com