Oil gathering element of fume exhauster

A technology for range hoods and oil collection, which can be used in the fields of oil fume removal, household heating, lighting and heating equipment, etc., and can solve problems such as difficult cleaning and increased production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

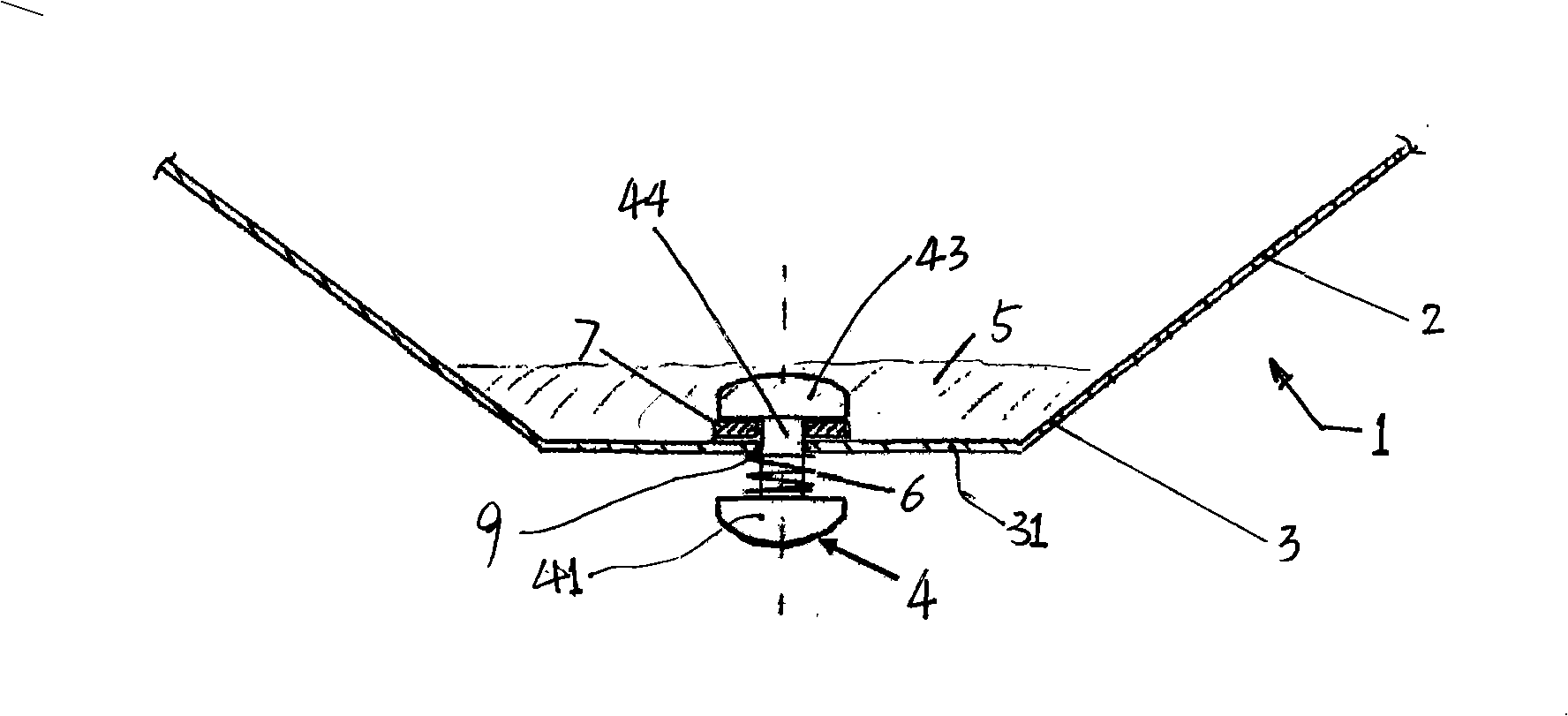

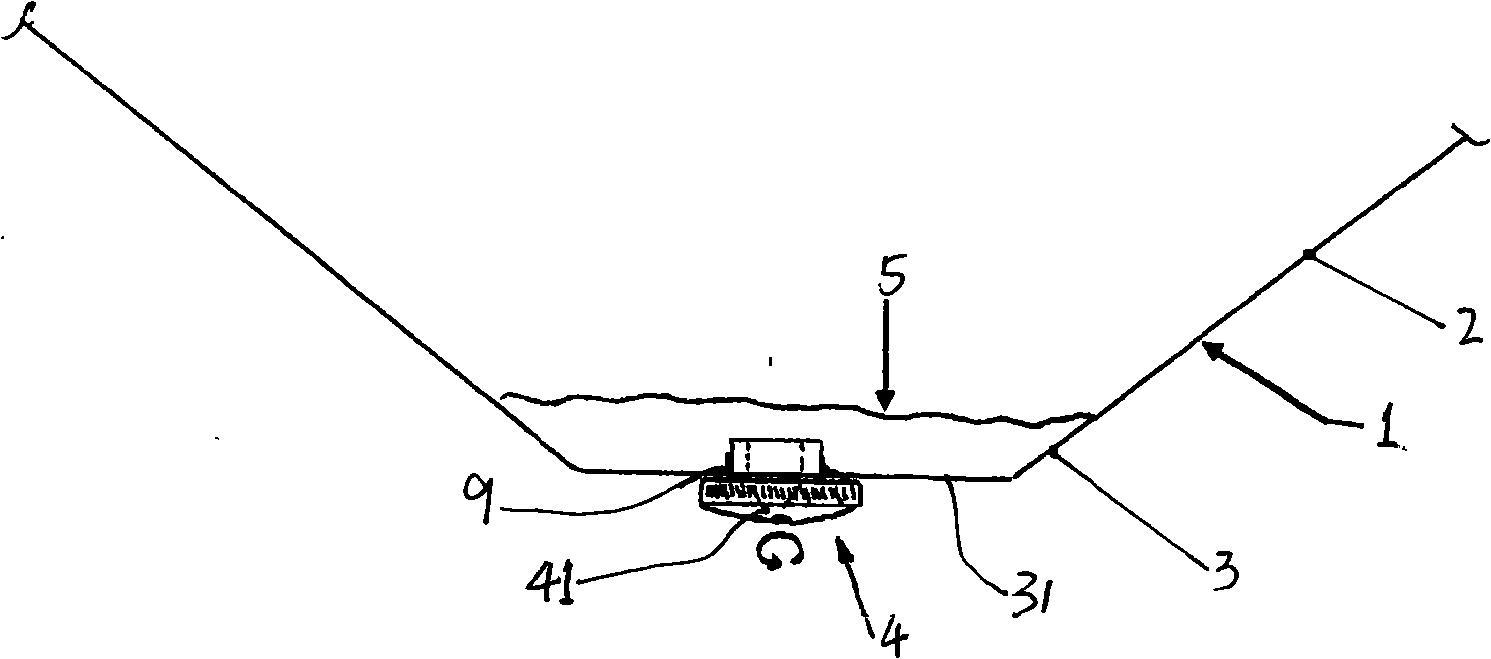

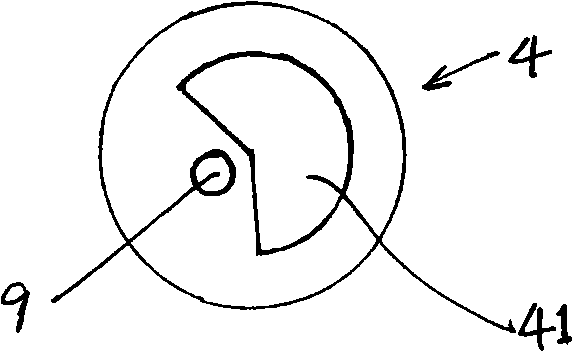

[0033] See attached figure 1 , an oil collecting element 1 of a range hood for collecting and discharging oil and moisture 5 generated during cooking, comprising, an oil guide member 2 with holes for collecting and guiding said oil and moisture, and an oil guide member 2 for collecting oil and moisture The oil collector 3 of water 5, the oil collector 3 is formed on the lower part of the oil guide 2, and the central part of the bottom plate 31 of the oil collector 3 is provided with an outlet 9 and an oil discharge device 4, and the oil discharge device 4 has a The trigger 41 discharges the oil and moisture 5 collected in the oil trap 1 after the user triggers it. The perforated oil guide 2 and the oil collector 3 are made of one piece of metal. For process or cost purposes, the two can also be set separately. The oil collector 3 has a capacity of at least 100 cubic centimeters of oil and water. The oil collector 1 is a truncated cone or a three-dimensional shape. In this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com