Cantilever member and manufacturing method thereof, magnetic head tab combination and disk drive unit

A disk drive and cantilever technology, which is applied to align the tracks on the disk, the hydrodynamic spacing of the head, and the direction of the support head. Write performance, reduce pitch and roll attitude changes, and simplify the effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

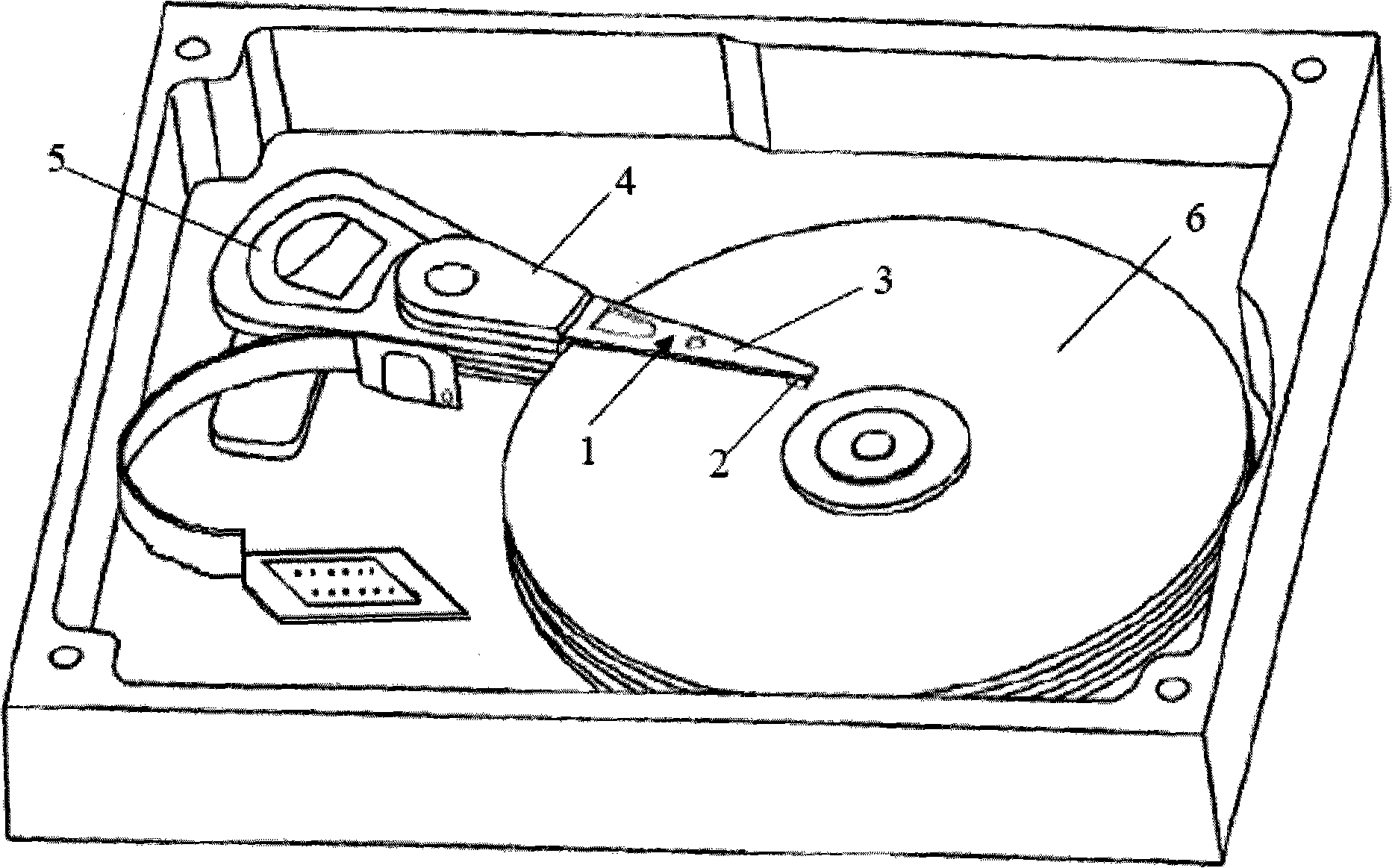

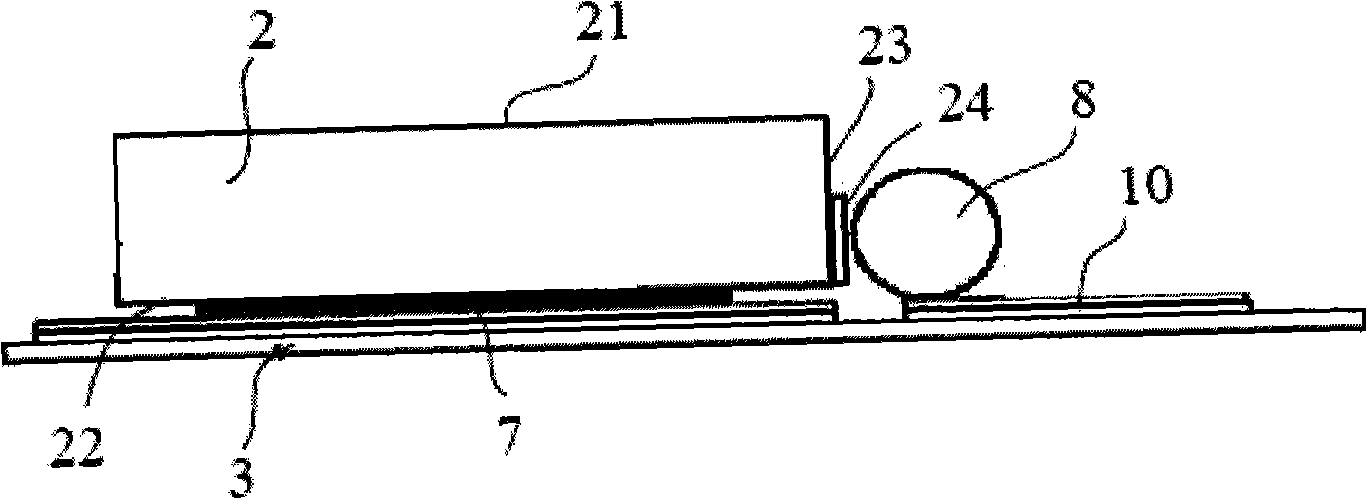

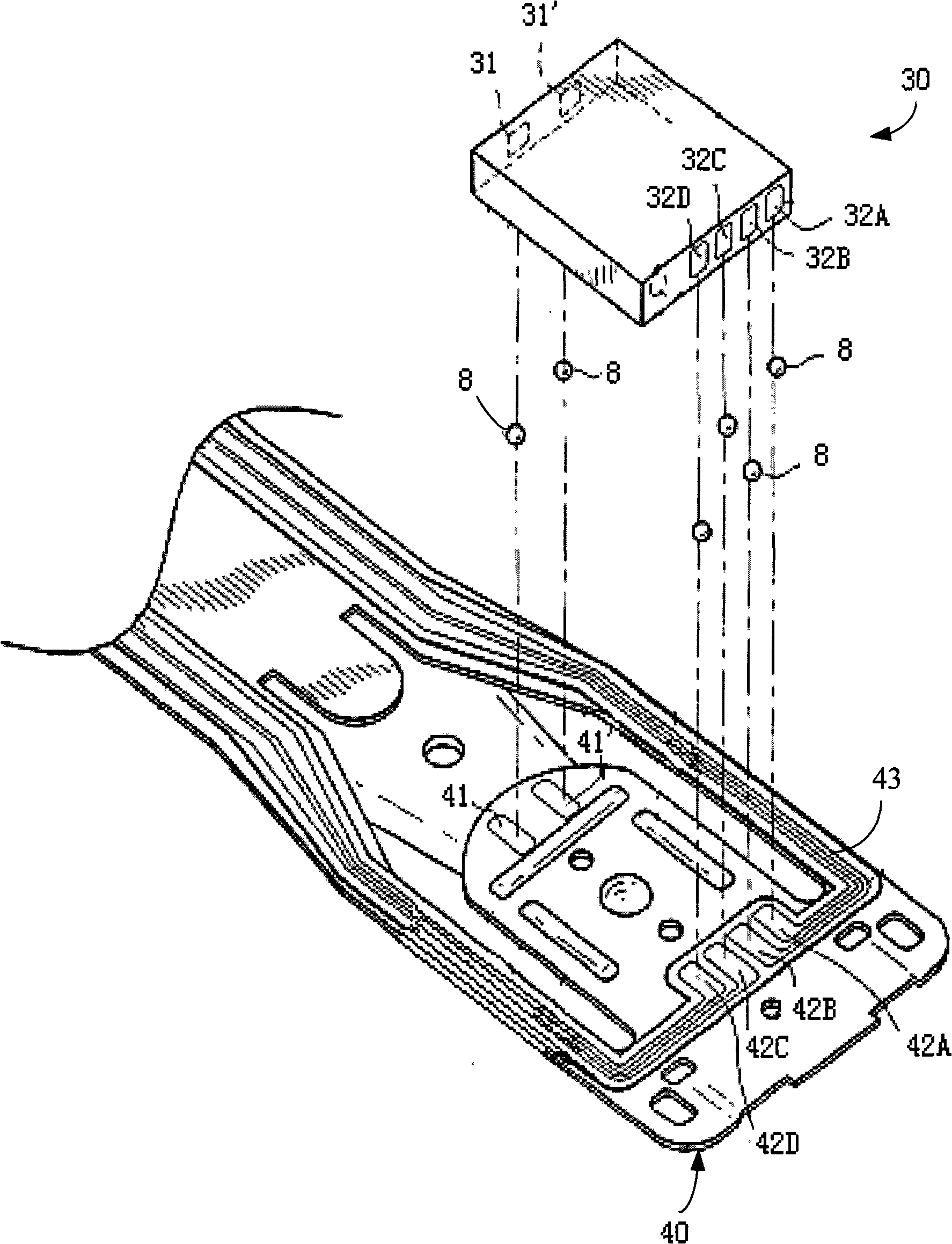

[0052] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. Refer to the accompanying drawings in detail below, Figure 4 It is a perspective view of the disk drive unit of the present invention, and FIG. 5 is a partially enlarged perspective view of the head gimbal assembly of the disk drive unit. In order to facilitate the understanding of the construction and configuration principles of the HGA and the disk drive unit, known components and characteristic components of the present invention will be described below.

[0053] Such as Figure 4 As shown, the disk drive unit includes a set of disks 904 spaced apart from each other and a HGA with a HGA 901 . The disk 904 rotates around a spindle motor. The HGA 901 includes a HGA 100 and a suspension 200 . The HGA 901 is connected to the driving arm 903 . The head actuator arm assembly rotates around an axis of the actuator arm 903 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com