Experimental powder mill

A pulverizer and skin grinding technology, applied in grain processing and other directions, can solve the problems of difficult installation and maintenance, high price, complicated and complicated design, etc., and achieve the effects of stable operation, low price and improved screening efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

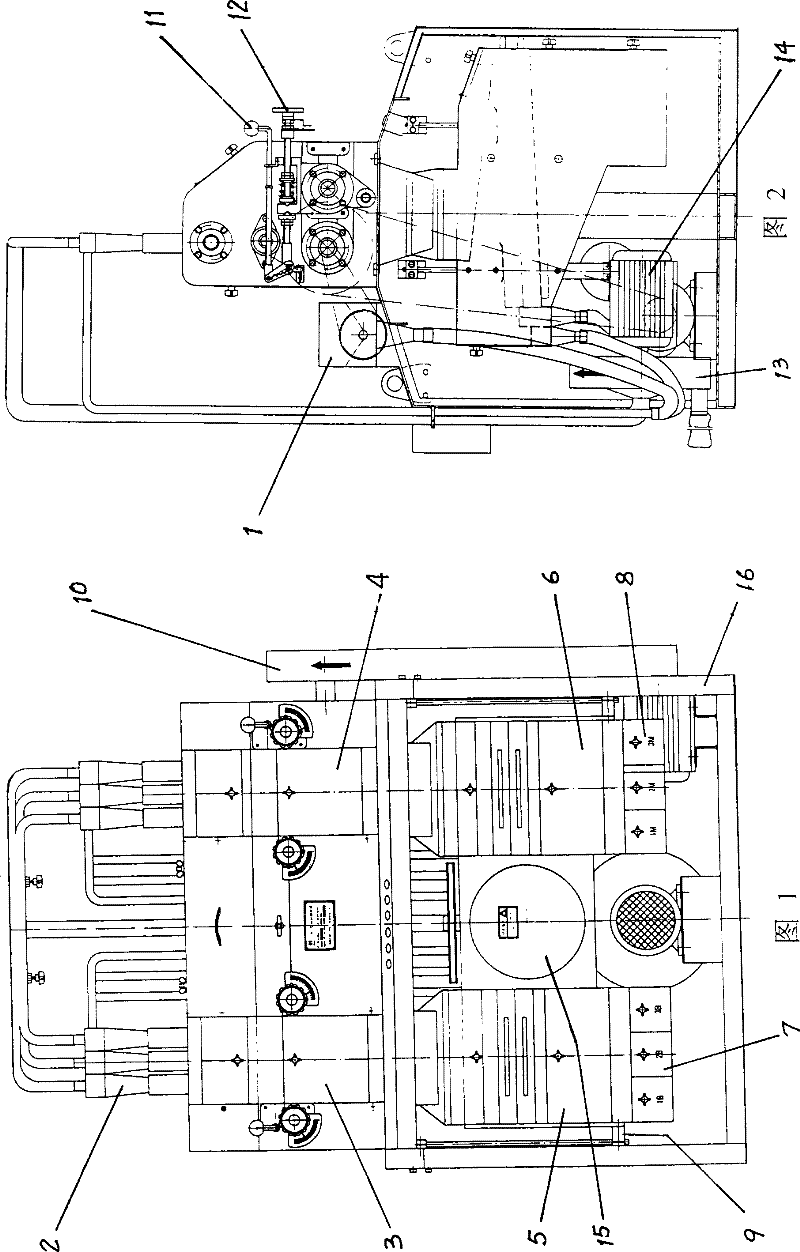

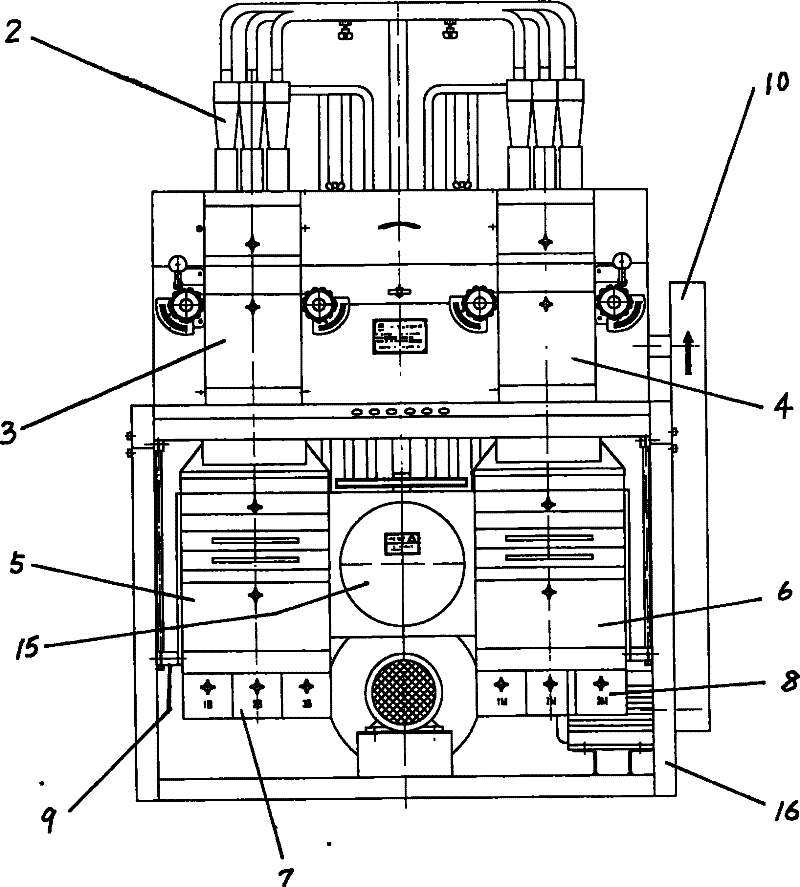

[0019] The present invention will be further described below in conjunction with the accompanying drawings. exist figure 1 , figure 2 In the feed structure 1, there is a forced feeding screw shaft with adjustable flow rate and a feed flow display. It changes the self-flow feeding controlled by the plugboard into a screw controllable feeding. On the one hand, it makes the "arching" during the feeding process "The material blocking phenomenon is completely solved, and on the other hand, it is convenient to adjust and display the feed flow rate; the air transport lifting mechanism 2 has six air supply pipes, and the middle sections of the six air supply pipes can be integrated, and the two ends are separated. Mechanism 3 or core grinding mechanism 4 and sieve body mechanism, and the cleaning chains to prevent material "arching" are installed in the six lifting and converting material ports; the skin grinding gear roller in the skin grinding structure 3 becomes a three-stage sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com