Method for improving migration velocity of smoke in electric precipitator and device

A technology of driving speed and electrostatic precipitator, which is applied in the direction of external electrostatic separator, electrode structure, electrostatic separation, etc., can solve the problems of poor performance of electrostatic precipitator, low driving speed of smoke and dust, and high operating cost, so as to improve performance, The effect of increasing the speed of soot drive and improving the ion transport rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

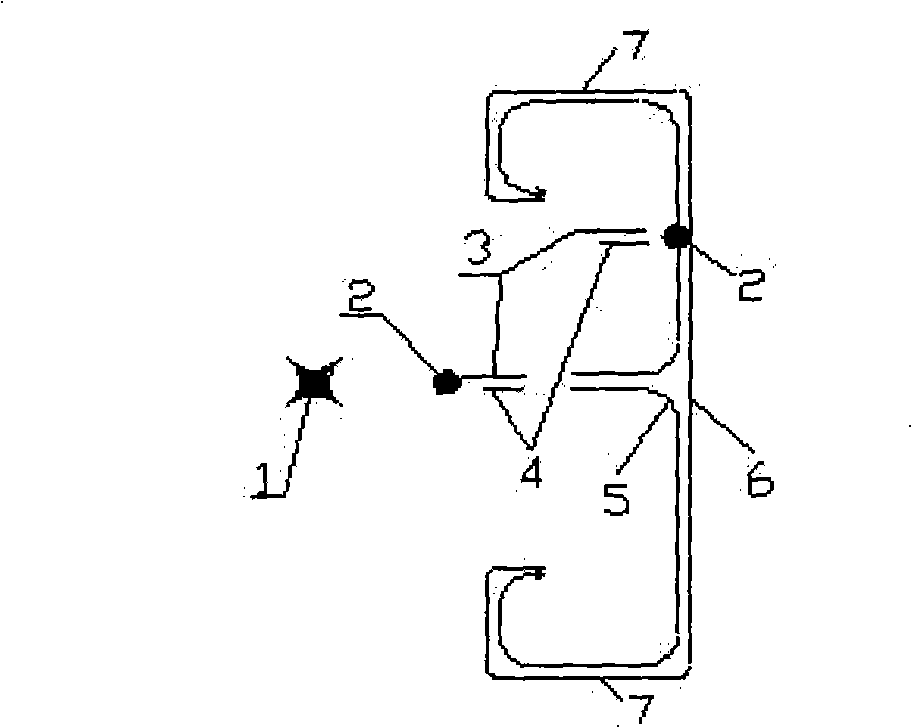

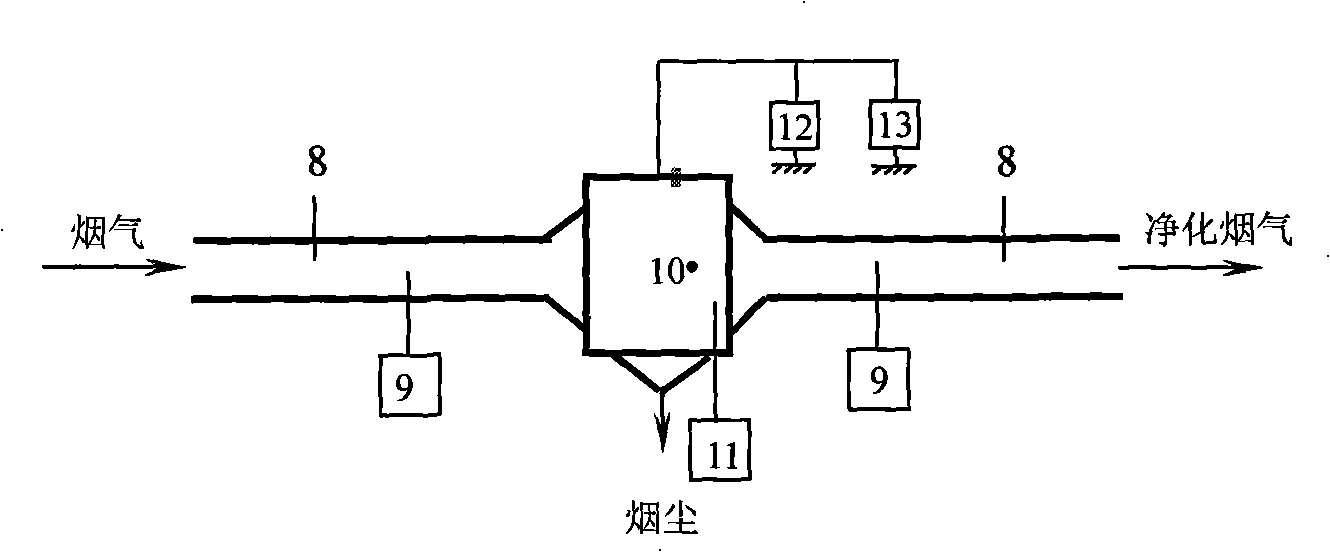

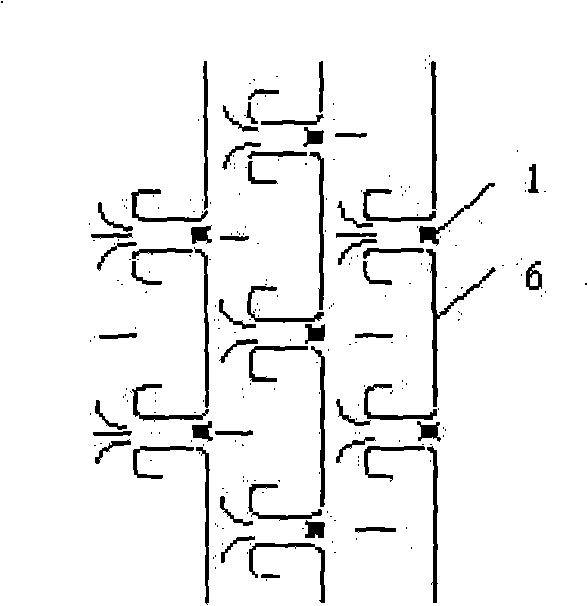

[0025] Such as image 3 As shown, the discharge electrode is placed in the gap between two adjacent dust-collecting plates facing the flue gas flow, that is, the discharge electrode 1 is set in the middle of the gap between the side plates 7 of the two adjacent dust-collecting plates 6 and close to the gap At the outlet end, the direction of the smoke and dust driving speed is the same as that of the flue gas flow. The distance between the sides of the two dust-collecting poles facing the airflow direction is about 30% of the width of the dust-collecting poles. Apply a DC voltage of 20-56kV between the discharge electrode and the dust collector. The metal discharge electrode and the dust collection electrode are adopted, and the gap between the dust collection electrode corresponds to the center line of the dust collectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com