Industrialized production process of benzoic anhydride

A technology of phthalic anhydride and industrial naphthalene, which is applied in the field of fixed-bed gas-phase catalytic oxidation to produce phthalic anhydride, can solve problems such as easy blockage of nozzles, insufficient and uniform mixing of naphthalene and air, and incomplete vaporization of industrial naphthalene, so as to avoid clogging, easy control, and high efficiency. Yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The 40,000 tons / year production plant of producing phthalic anhydride with industrial naphthalene is example below, introduces the present invention in more detail.

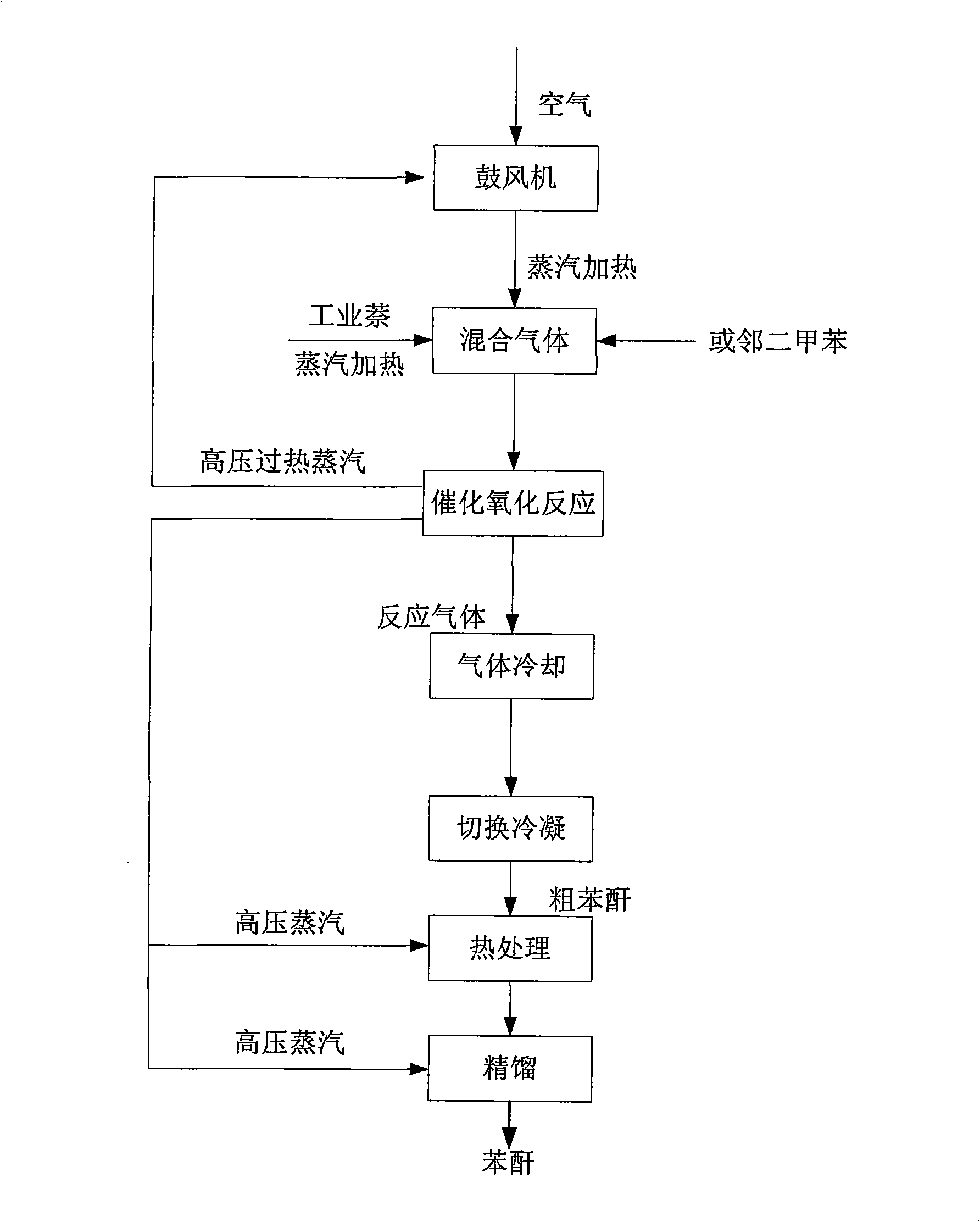

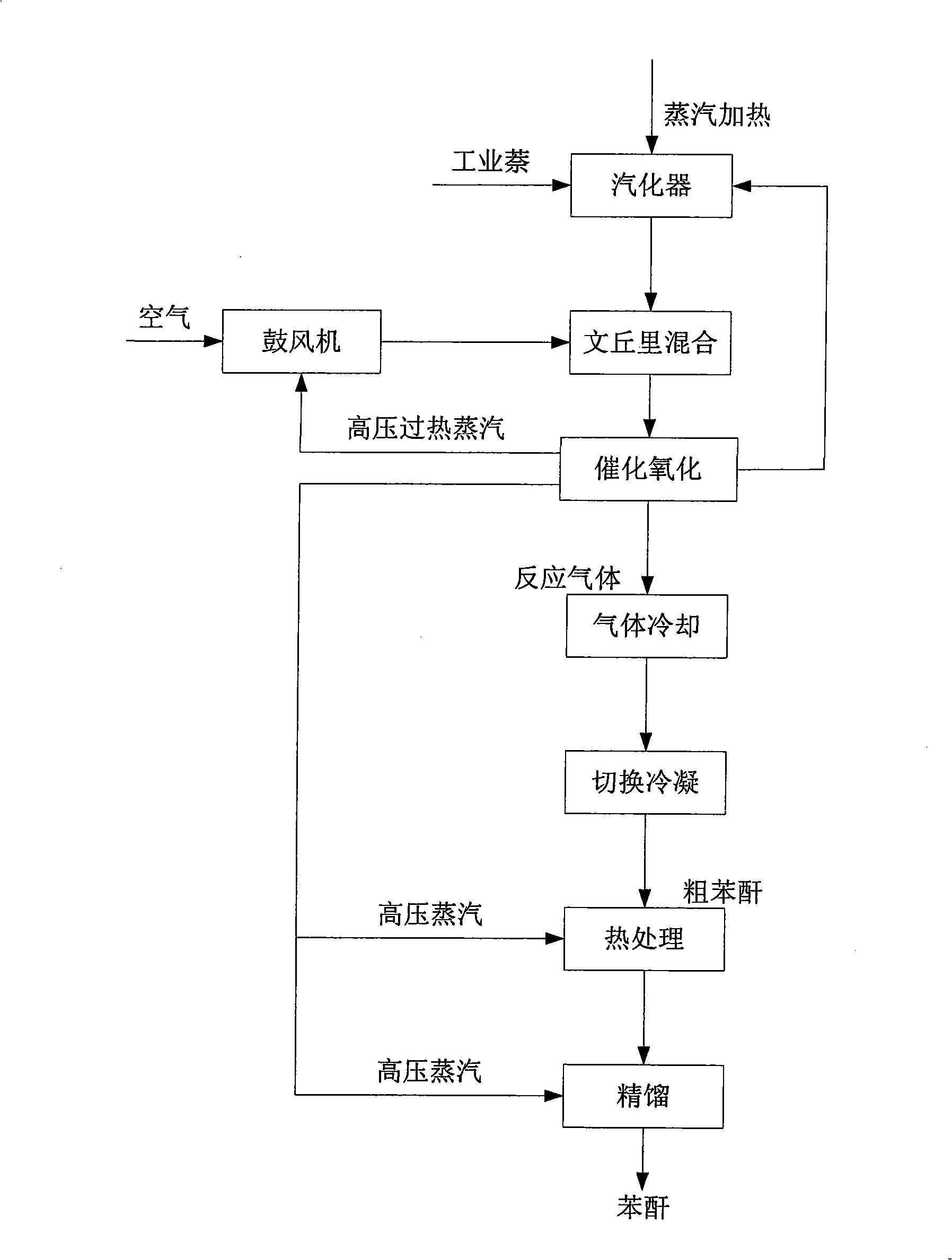

[0065] The technical process of industrial naphthalene of the present invention producing phthalic anhydride is as figure 2 shown.

[0066] After the industrial naphthalene is heated and completely vaporized in the vaporizer, it is mixed with the heated and pressurized air through the Venturi tube and enters the naphthalene-air mixer. The fully and uniformly mixed naphthalene-air mixture enters the fixed-bed catalytic reactor for catalytic oxidation to produce Phthalic anhydride.

[0067] In order to ensure that the product phthalic anhydride yield can reach 106%, one of the key processes is complete vaporization of industrial naphthalene and sufficient mixing with air, so different vaporization and mixing methods of industrial naphthalene have a direct impact on the yield of phthalic anhydride.

[0068...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com