Improved process of steam generator for malacia protection of enamelling bare wire as well as apparatus

A steam generator and bare wire technology, applied in electrical components, circuits, conductor/cable insulation, etc., can solve the problems of enameled wire scrapping, unfavorable enameled wire, bare wire oxidation, etc., and achieve the effect of saving electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

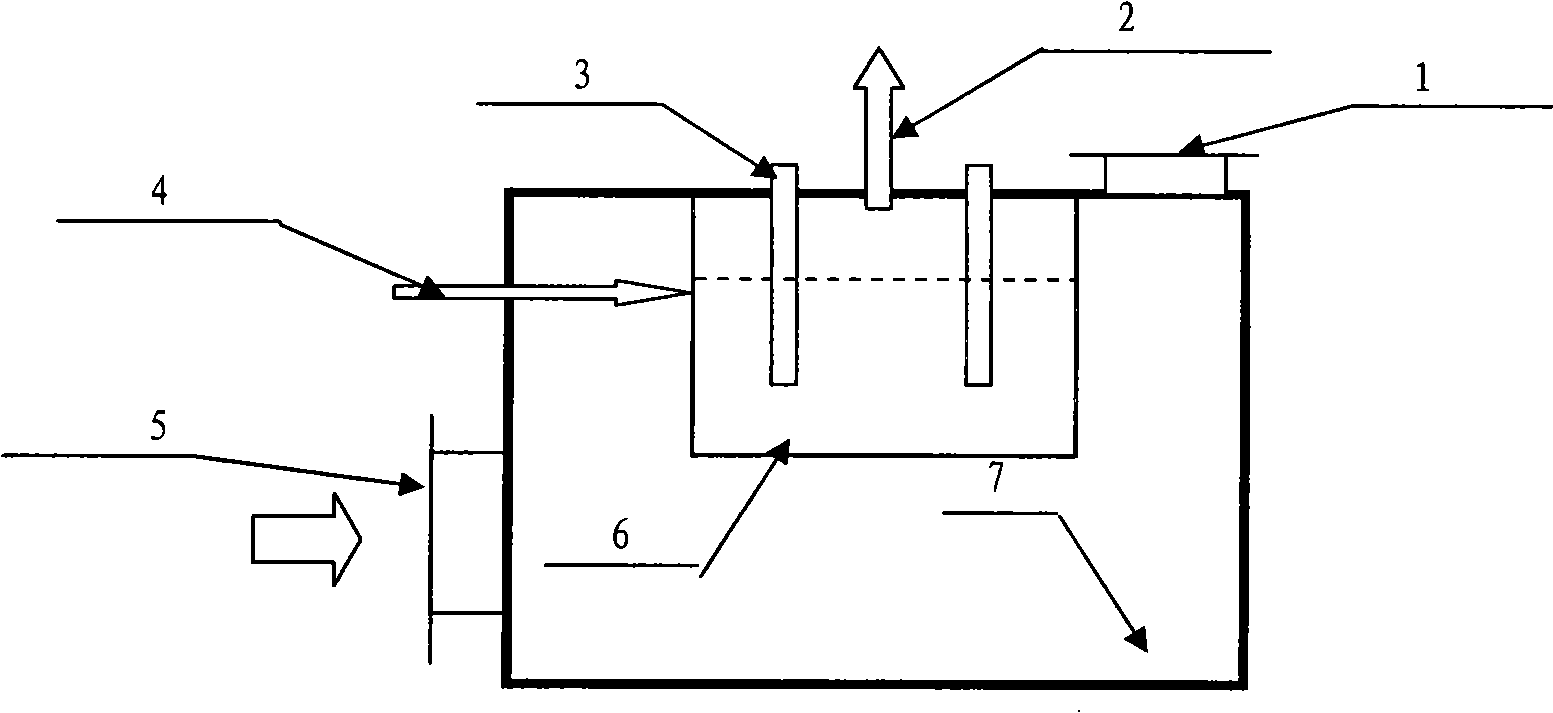

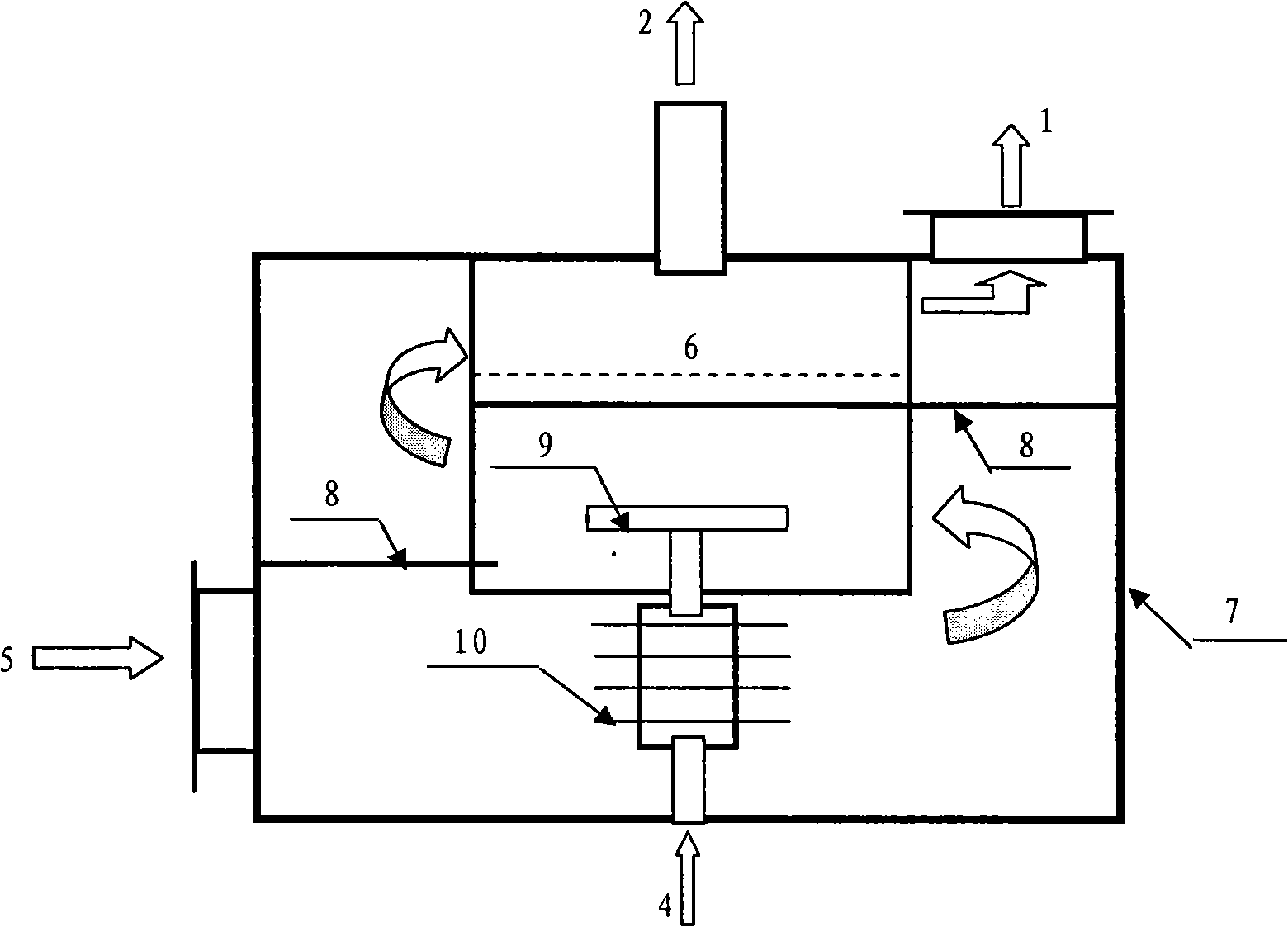

[0020] exist figure 2 In the present invention, the improved device of the steam generator for softening and protecting enameled bare wires does not change the position of the exhaust gas outlet (1) and the steam outlet (2), and firstly changes the exhaust gas inlet (5) from the bottom to the side, " The T"-shaped water inlet pipe (9) is arranged at the bottom of the inner water tank (6) and the outer bladder (7). The "T"-shaped water inlet pipe (7) at the bottom of the inner water tank (6) is closed at both ends of the horizontally placed water inlet pipe, and a row of small holes is punched at the bottom as the water outlet. The heat collecting sheet (10) is thick and wrapped; the inner water tank (6) is arranged in the middle of the outer tank (7), and two staggered heat insulation boards (8) are arranged along the bottom and the middle of the inner water tank (6), so that the The inner part of the outer bladder (7) is separated into a closed channel with opposite directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com