Magnetic field forming device

A magnetic field and forming body technology, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve problems such as cracks or gaps in the forming body 100, damage to the forming body 100, and prolongation of the production cycle time to achieve production cycle time Effects of shortening time, reducing impact, and suppressing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

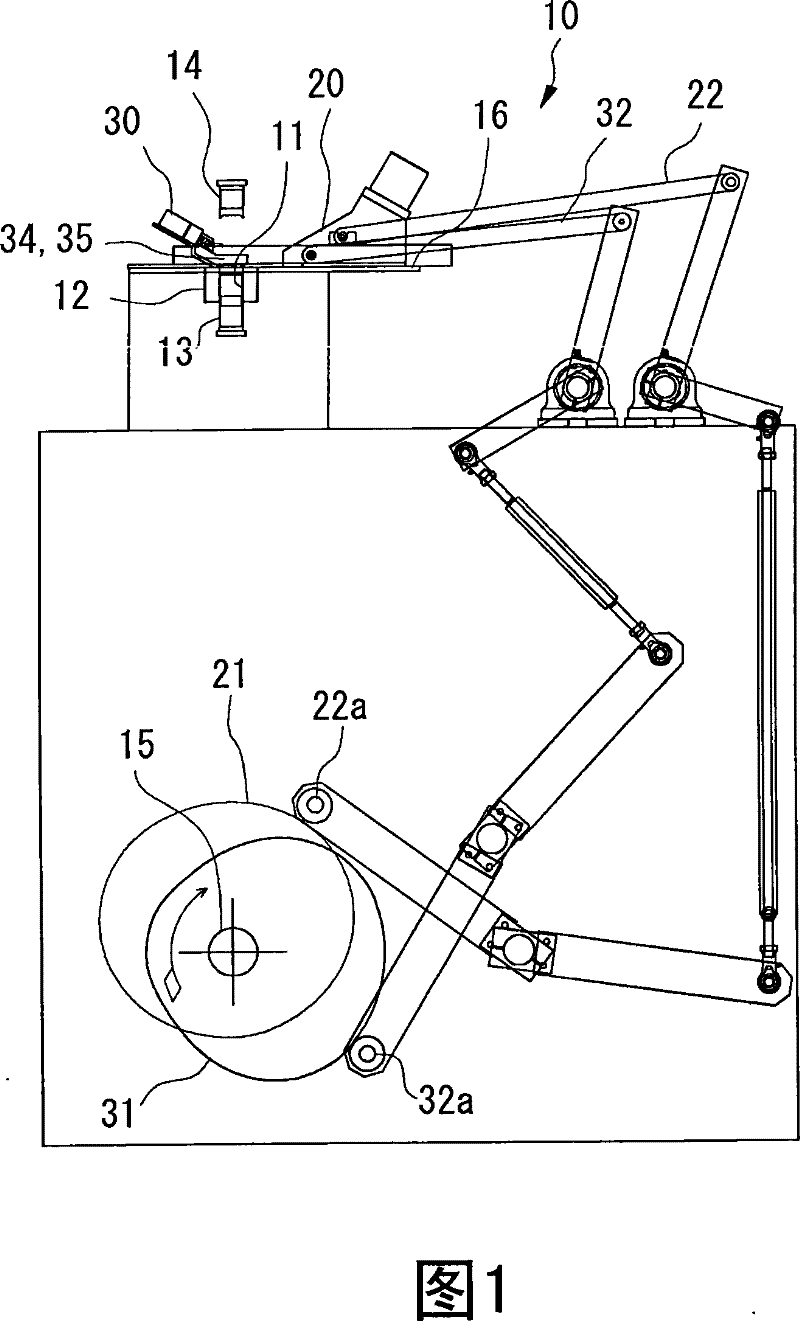

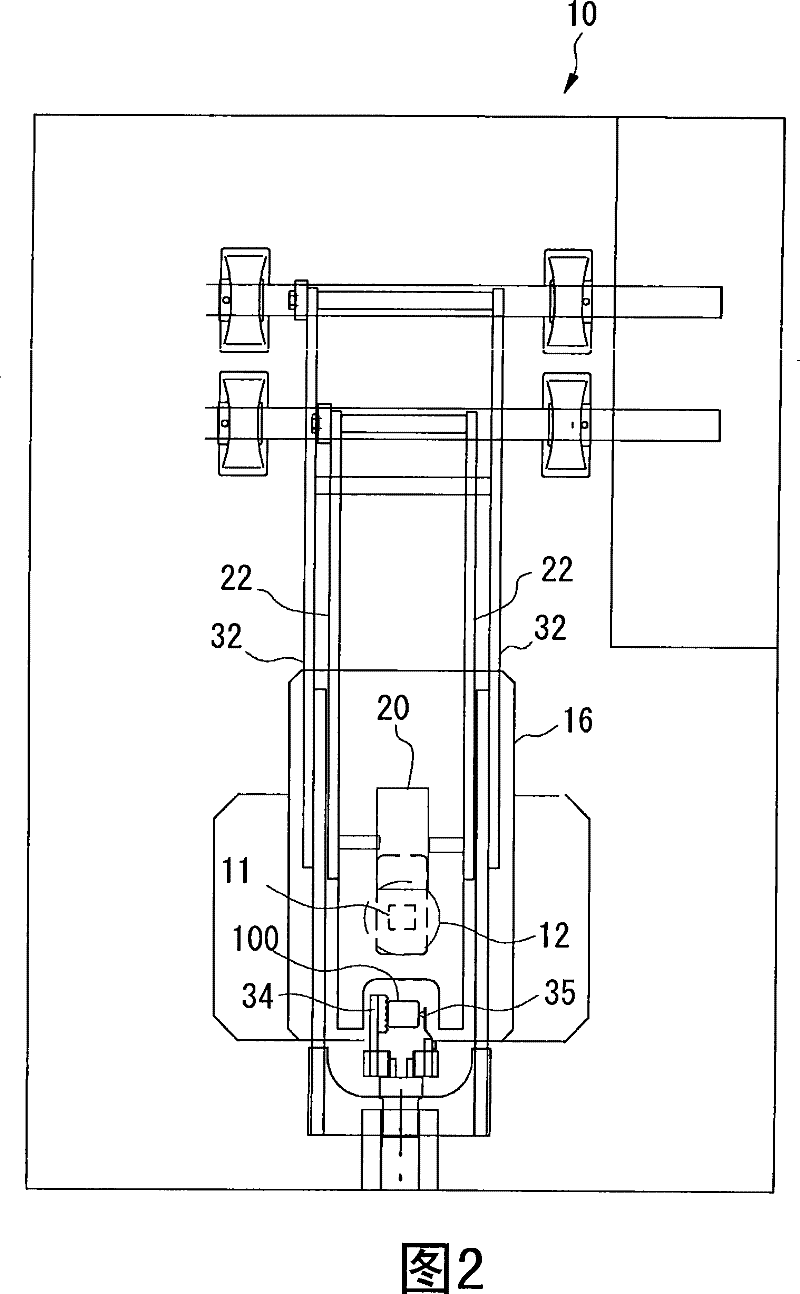

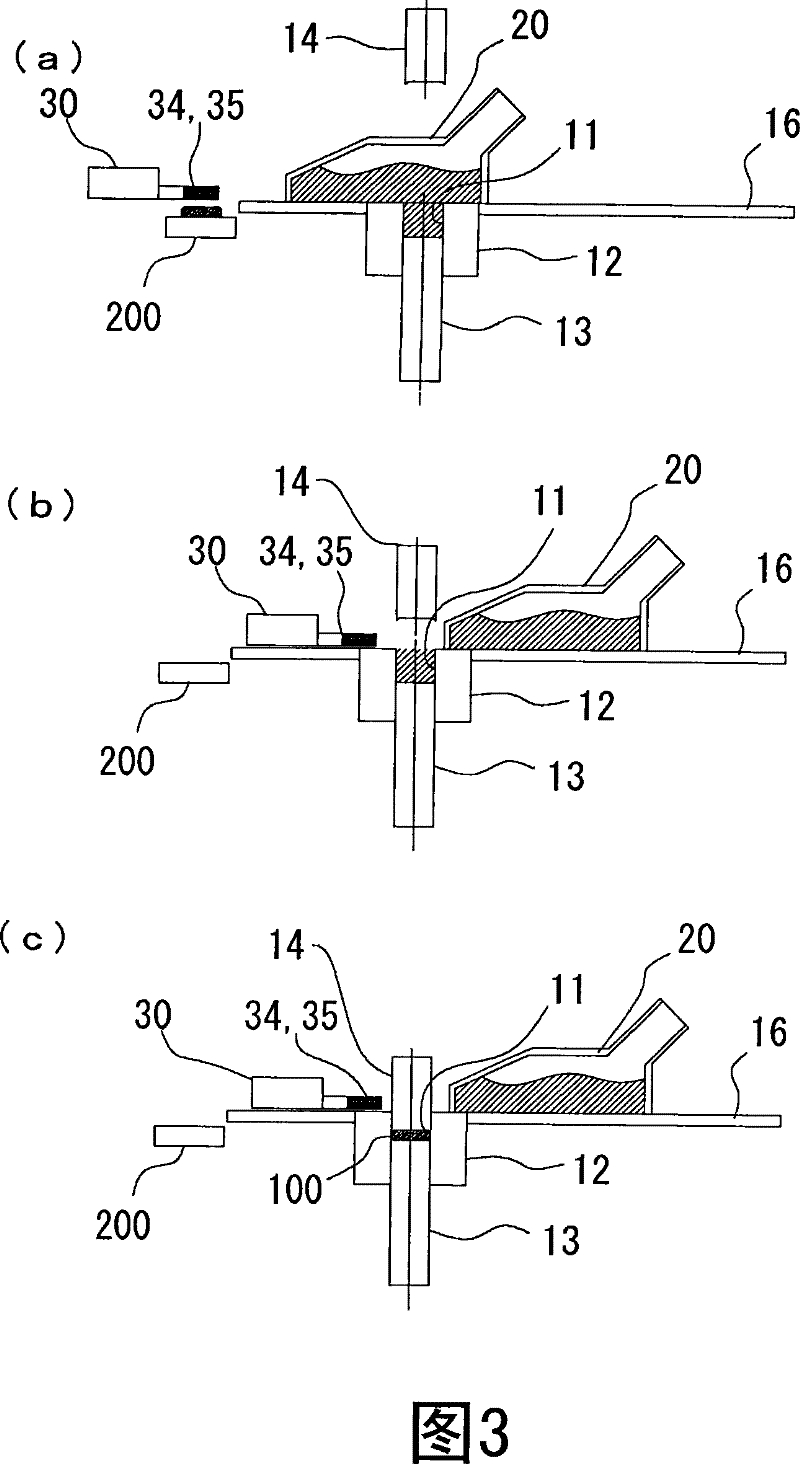

[0040] The present invention will be described in detail below based on the embodiments shown in the drawings.

[0041] The ferrite magnet obtained by sintering the molded body formed by the magnetic field shaping device of this embodiment is preferably set to have ferrite with a hexagonal crystal structure as the main phase. A substance that is at least one element among Pb and must contain Sr is represented by A, and a substance that is at least one element selected from rare earth elements (containing Y) and Bi and that contains La as an essential element is represented by R , and when Co, or Co and Zn is expressed as M, it contains A, R, Fe and M;

[0042] When by formula (1) A 1-x R x (Fe 12-y m y ) z o 19 (x, y, z are the number of moles) when expressing, then satisfy following condition:

[0043] 0.04≤x≤0.5

[0044] 0.04≤y≤0.5

[0045] 0.7≤z≤1.2

[0046] 1≤(x / y)

[0047] Such a ferrite magnet can be produced through the following steps.

[0048]In addition, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com