Material cutting device of reinforced bar-straightening and material-cutting machine

A cutting-off and reinforcement technology, applied in the field of machinery, can solve the problems of large waste of material, high labor intensity, and low work efficiency, and achieve the effects of reducing noise, ensuring stability, and preventing rigid impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

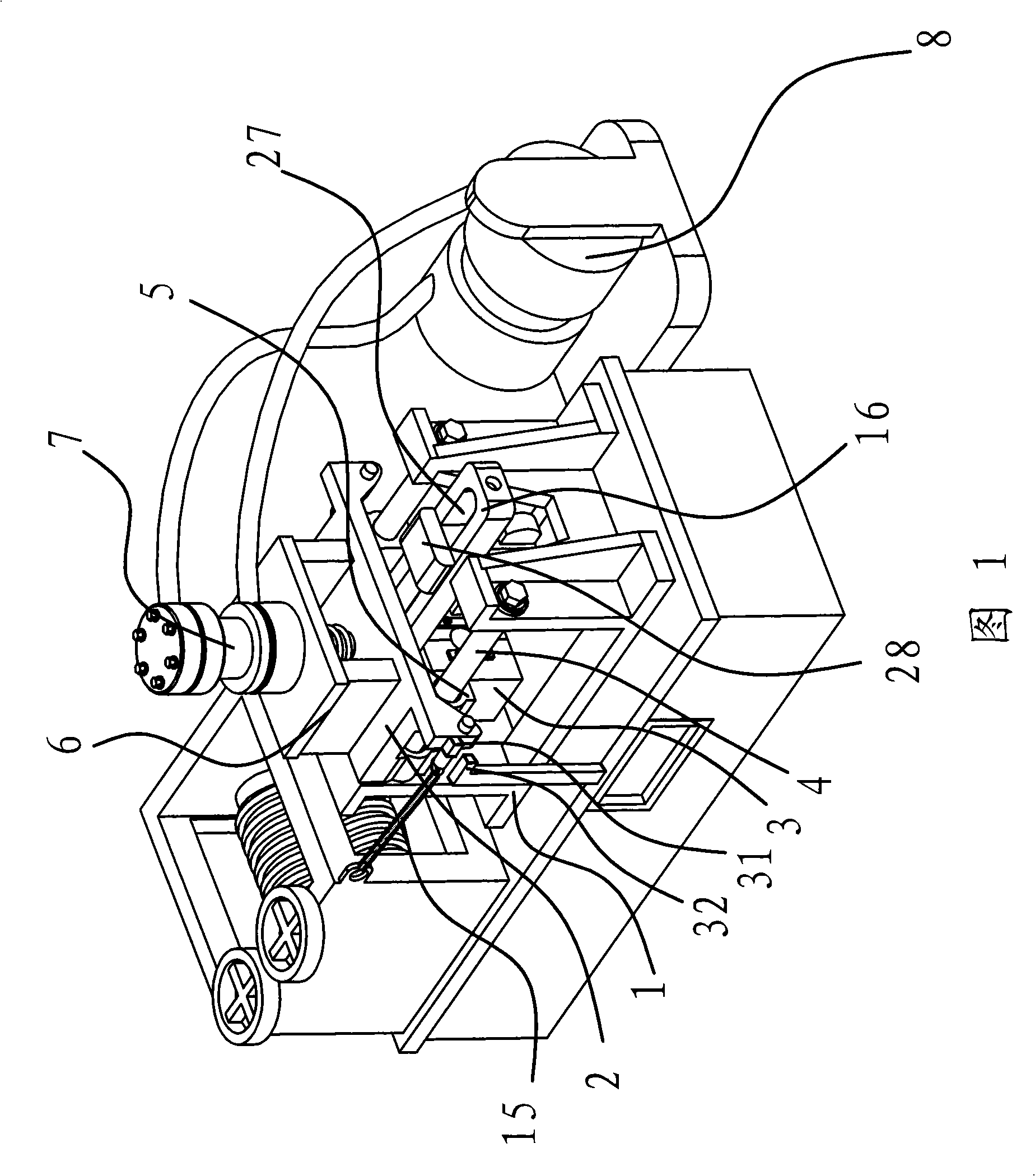

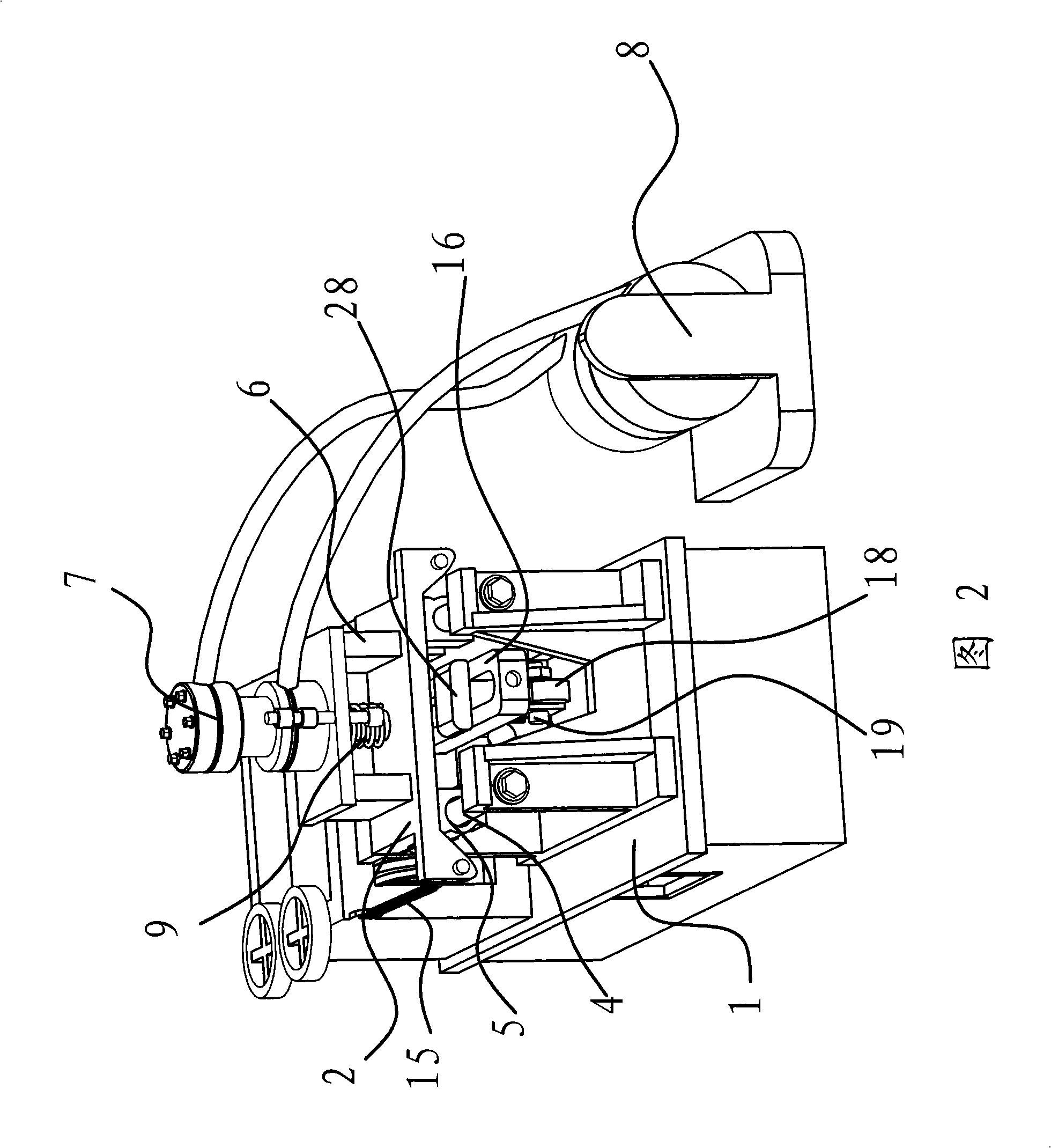

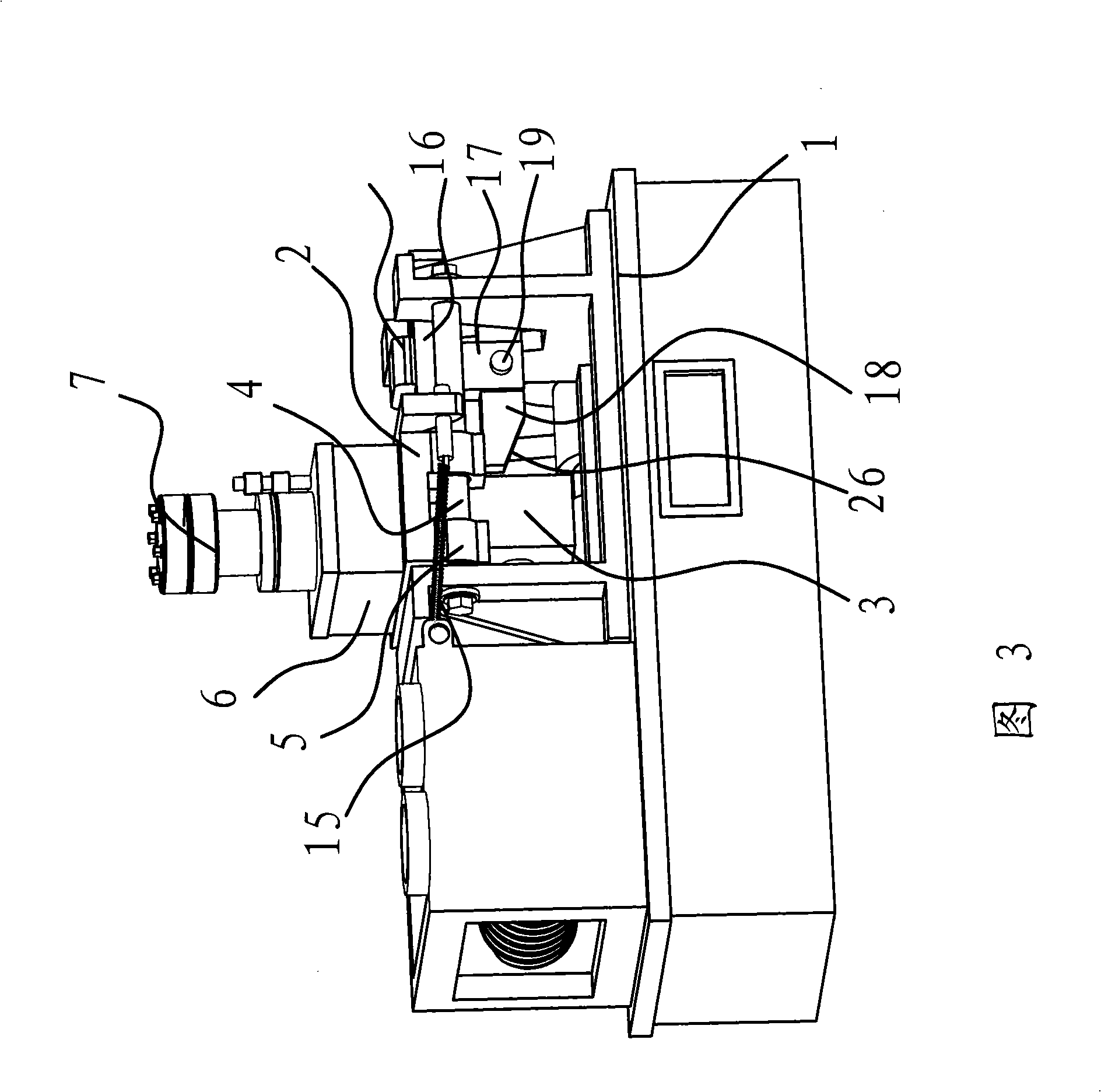

[0029]As shown in Figure 1, Figure 2, Figure 3, Figure 4 and Figure 5, the cutting device of the steel bar straightening and cutting machine includes a machine base 1, a slide table 2, a cutting mold 3, a driving mechanism and a length-setting mechanism, On the base 1, there are two horizontal guide rails 4 arranged in parallel. The guide rails 4 are cylindrical guide rails. Each guide rail 4 is equipped with two linear bearings 5, and a flat slide table is set on the linear bearings 5. 2. In this way, the slide table 2 can move back and forth along the guide rail 4. A support base 6 is fixed on the slide table 2, and a drive mechanism is installed on the support base 6. The drive mechanism is a hydraulic cylinder 7 fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com