Vehicle maintenance prompting system

A vehicle and system hardware technology, which is applied in vehicle maintenance, vehicle maintenance/repair, registration/instruction of vehicle operation, etc. It can solve problems such as delayed maintenance, early maintenance of vehicles, and dislocation of maintenance time and maintenance time, and achieves low price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

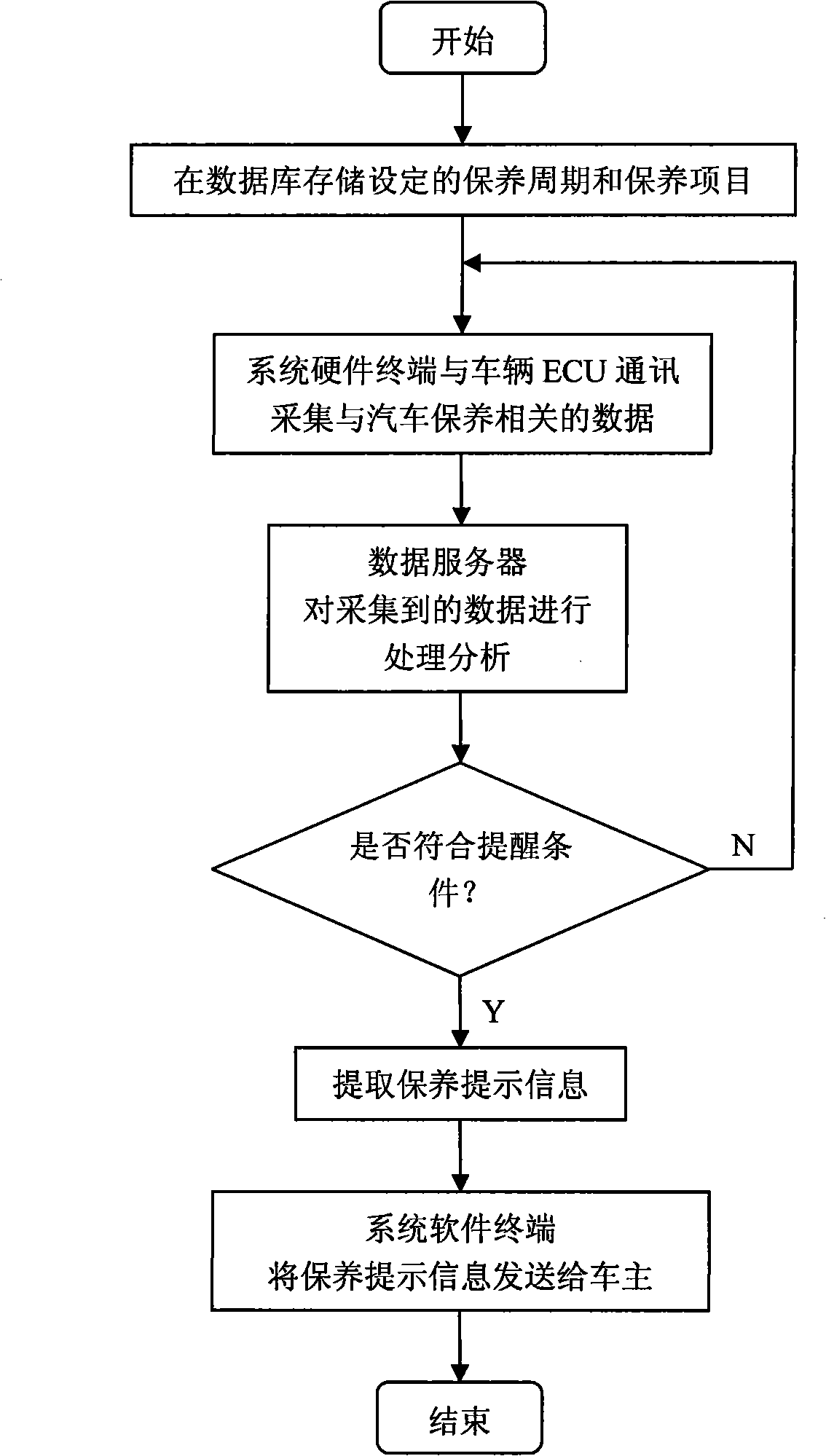

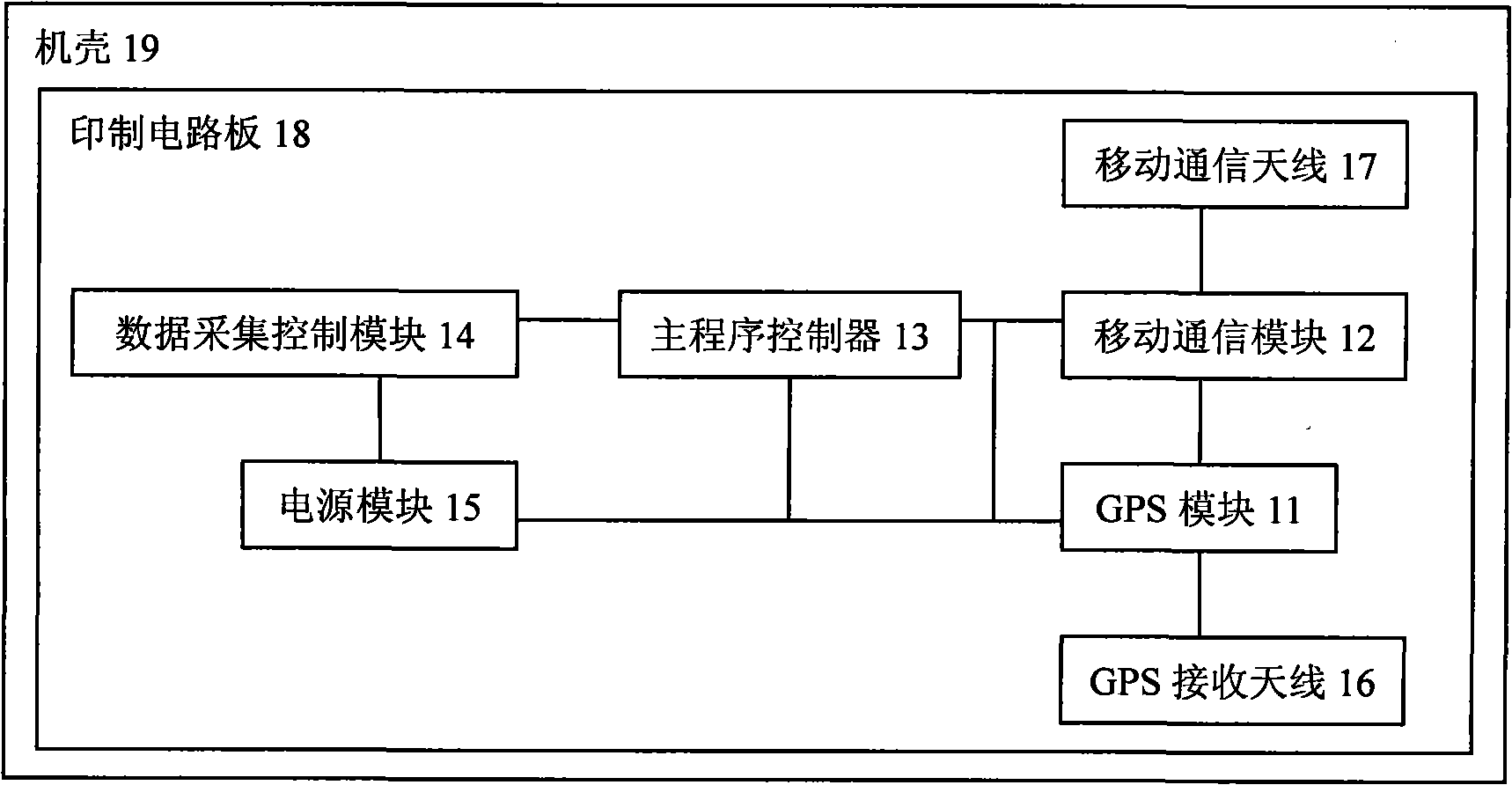

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings.

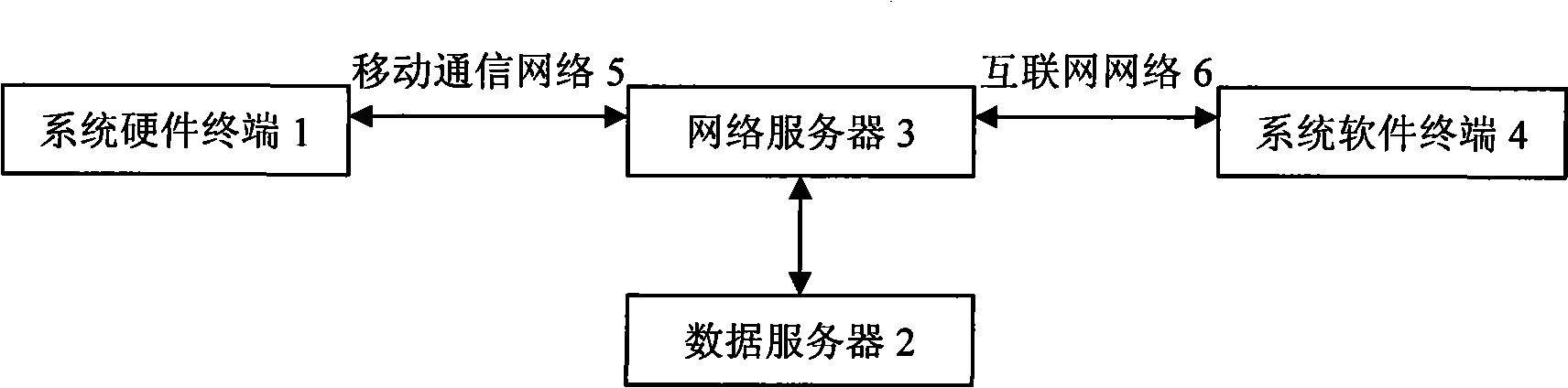

[0037] figure 1 The structure of the vehicle maintenance reminder system according to the present invention is shown, which includes: system hardware terminal 1; data server 2; network server 3; system software terminal 4; mobile communication network 5;

[0038] The system hardware terminal 1 has the ability to collect vehicle driving-related data and wireless communication capabilities, and is used to collect parameter information related to vehicle maintenance, store the collected parameter information related to vehicle maintenance, and send the collected parameter information through the mobile communication network 5 Parameter information related to vehicle maintenance.

[0039]The data service terminal 2 has a database for storing parameter information related to vehicle maintenance, receives the parameter information related to vehicle maintenance from the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com