Active energy ray-curable ink-jet ink

A technology of active energy rays and inkjet inks, applied in inks, printing, copying/marking methods, etc., can solve the problems of inaccessibility, large extension processability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

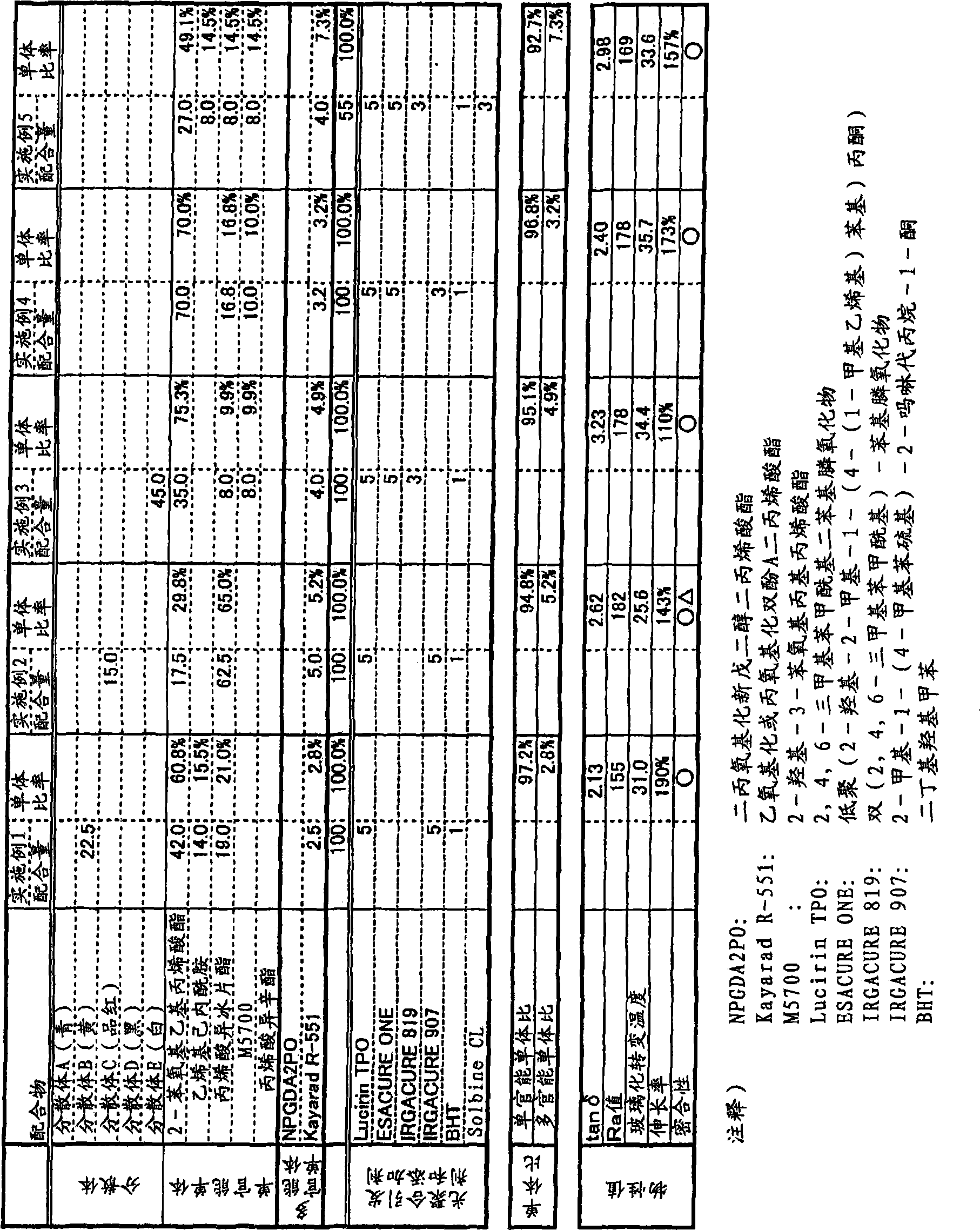

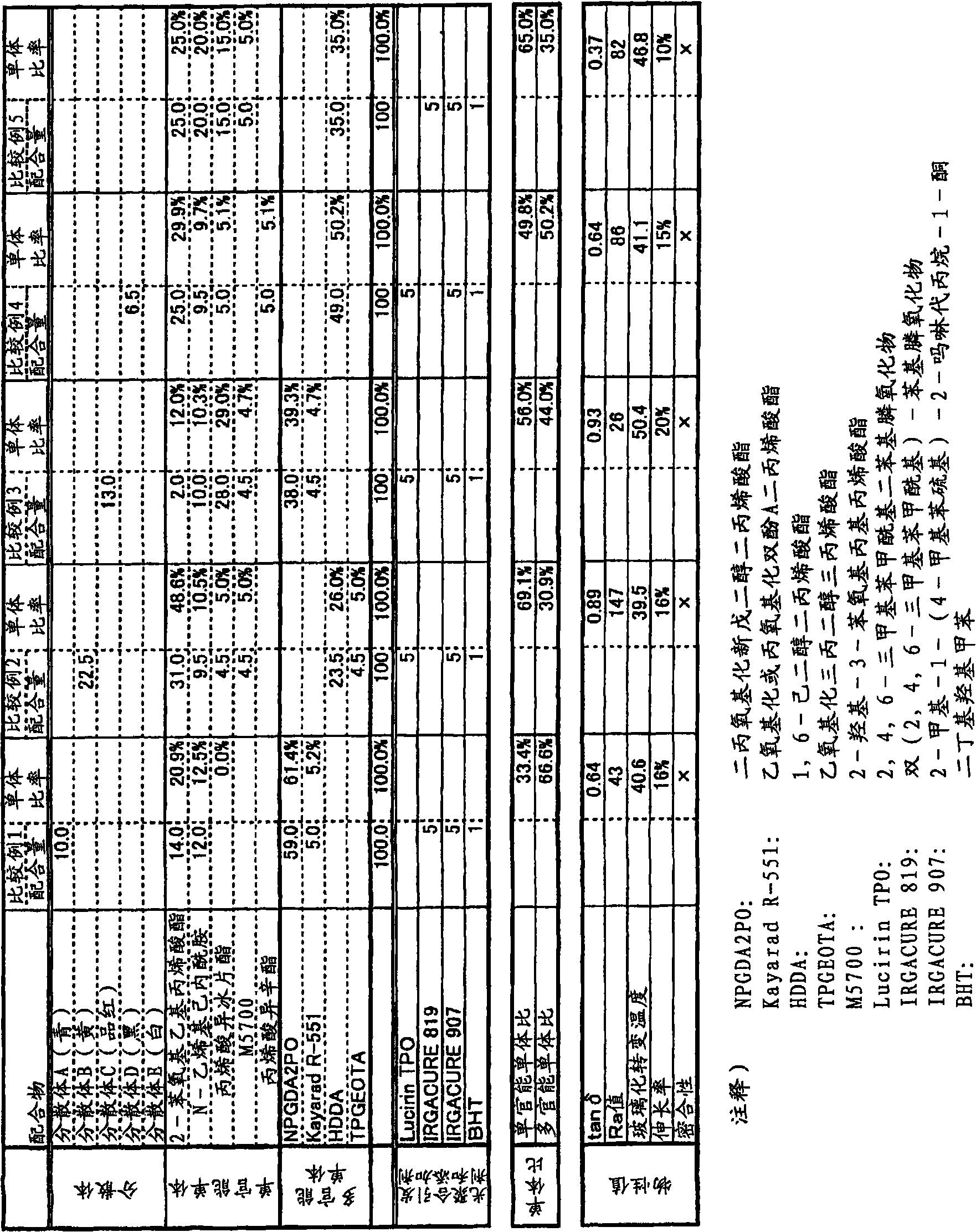

[0093] Add the ingredients in Table 1 sequentially from the top of the table while stirring. After stirring for 2 hours, it was confirmed that there was no dissolved residue, and the mixture was filtered with a membrane filter to remove coarse particles causing clogging of the inkjet head to prepare an ink. The ink was dispensed onto a polyethylene plate by an inkjet dispenser. Immediately after the ink was discharged, the 120W / cm high-pressure mercury lamp manufactured by Harrison Toshiba Lighting Co., Ltd. was used for ultraviolet curing at a conveying speed of 5m / min, an irradiation distance of 10cm, and 1Pass to obtain a coating film. After 24 hours, the coating film was slowly peeled off from the polyethylene plate, and the dynamic viscoelasticity was measured. In addition, in order to measure the Ra value, the ink was discharged onto a polycarbonate plate, and one minute after the ink was discharged, the polycarbonate plate was washed with isopropyl alcohol to remove th...

Embodiment 2~5

[0095] In the same manner as in Example 1, inks were prepared according to the description in Table 1, and printed and cured.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com